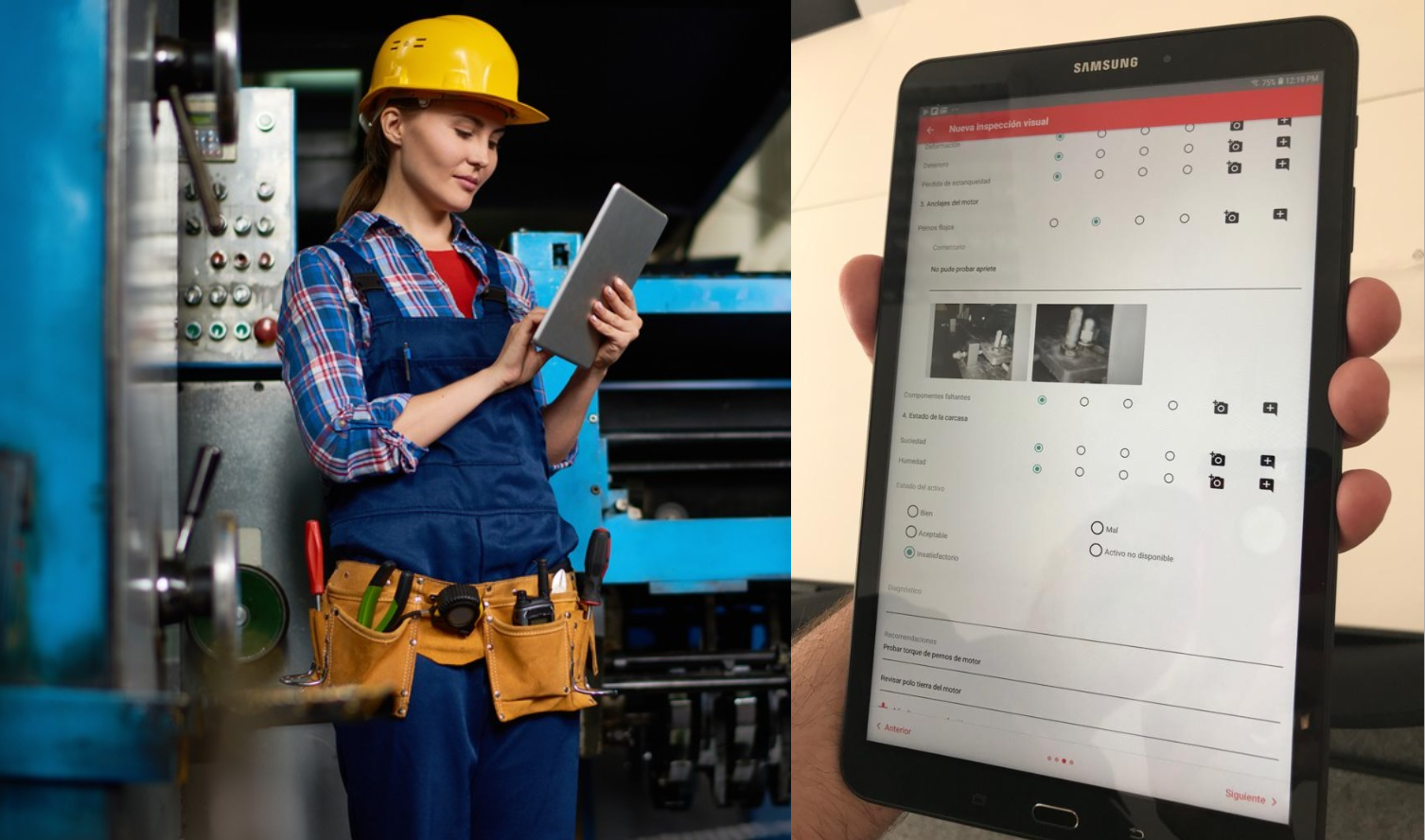

The digital collection implies the direct computerization of the data without going through the paper. Therefore, it is necessary to equip the inspectors with tablets or cell phones for data collection. This means that previously paper-based visual inspection forms or templates are available on inspectors' tablets.

The first step of visual inspections' digital transformation is to configure or design the paper templates to a digital format for data collection. This is possible through the Power-MI cloud software and its application for visual inspections.

Two configurations need to be tailored for each asset: parameters and inspection guidelines.

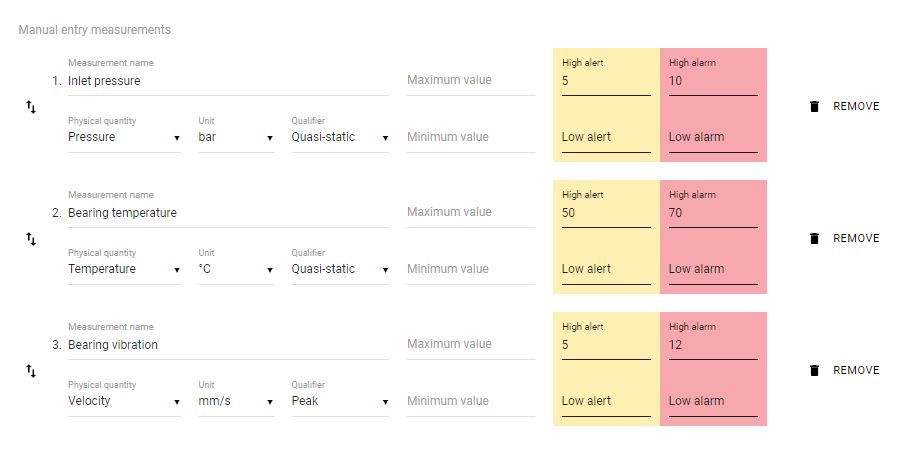

Parameter collection settings

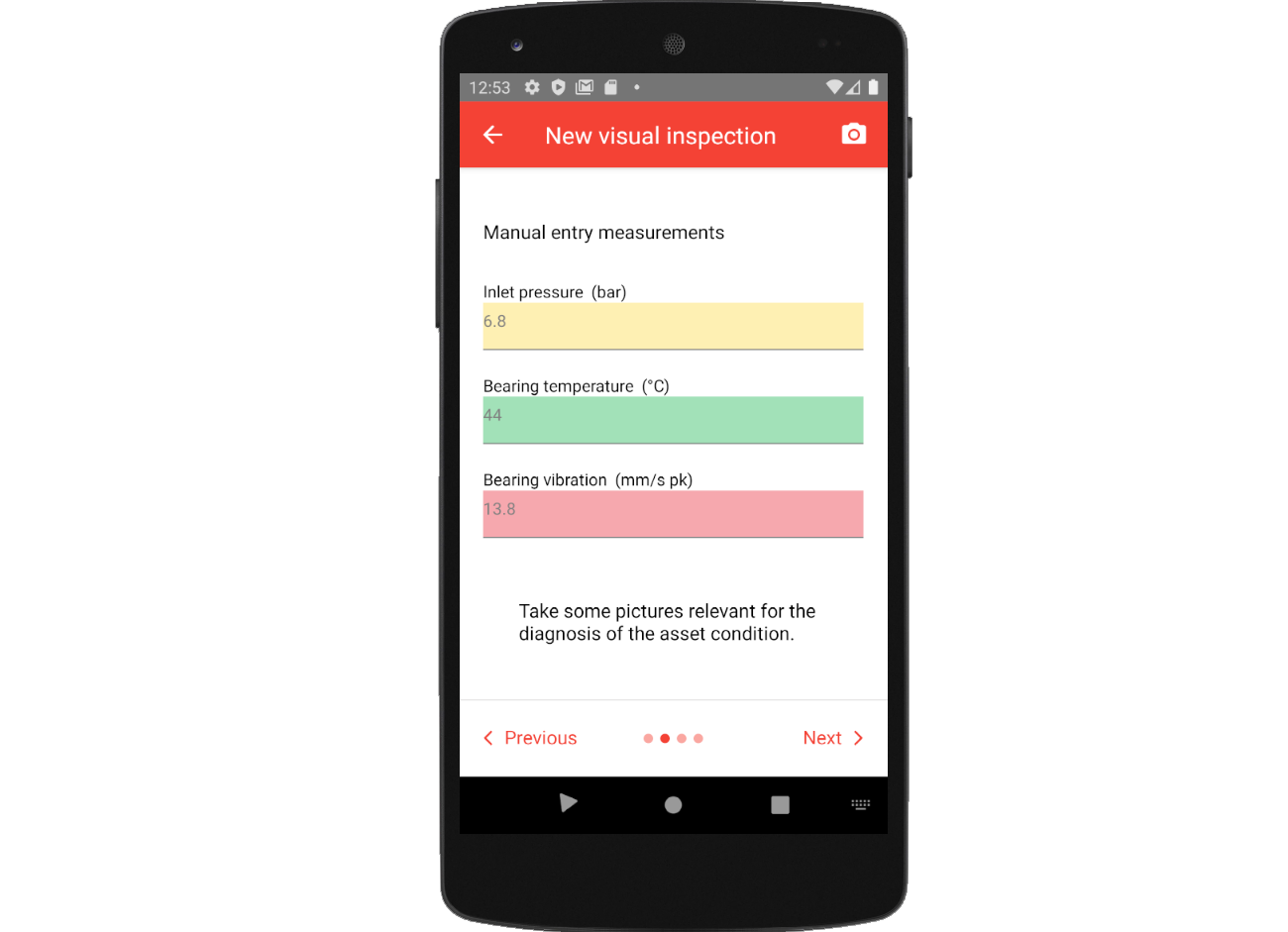

The parameters for digitizing visual inspections must be collected with manual data entry on the tablet and an automatic on-site evaluation regarding the pre-configured acceptable limits. Depending on the status of the parameter readings, the inspector might make additional checks. Therefore, the administrator of visual inspections must configure the following for each parameter:

- Name of the measure.

- Physical magnitude.

- Unit in which it will be collected.

- Amplitude type.

- Minimum and maximum value to display trend.

- Alert and alarm levels.

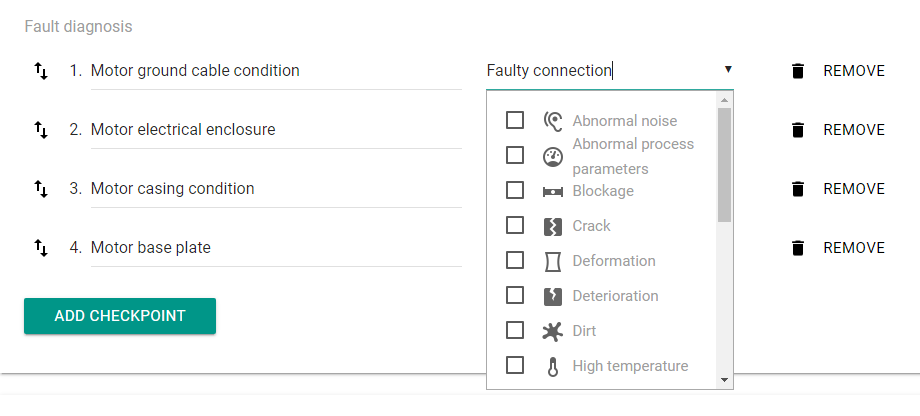

Setting up inspection guidelines

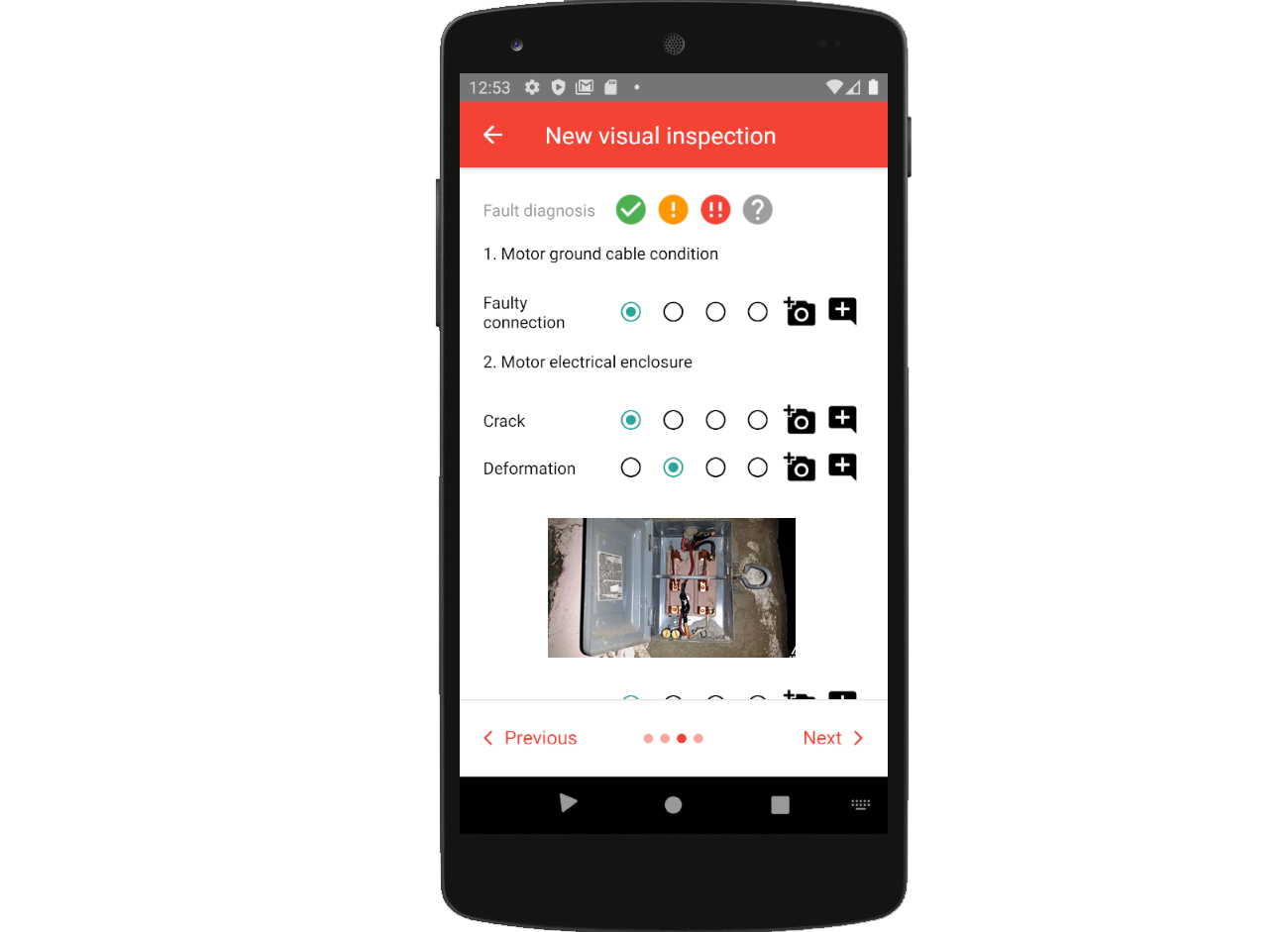

Inspection points and failures are defined in the inspection guidelines. These failures must come from a previous failure mode analysis of the asset. This is key to aligning visual inspections with the predictive maintenance plan.

The faults that can be associated with each inspection point are:

- Abnormal process parameters

- Obstruction

- Breaks

- Deformation

- Deterioration

- Dirt

- High temperature

- Humidity

- Leaks

- Loose bolts

- Bad connection

- Loss of tightness

- Lubrication problem

- Misadjustment

- Missing components

- Abnormal noise

- Corrosion

- Structural problems

Visual inspection application

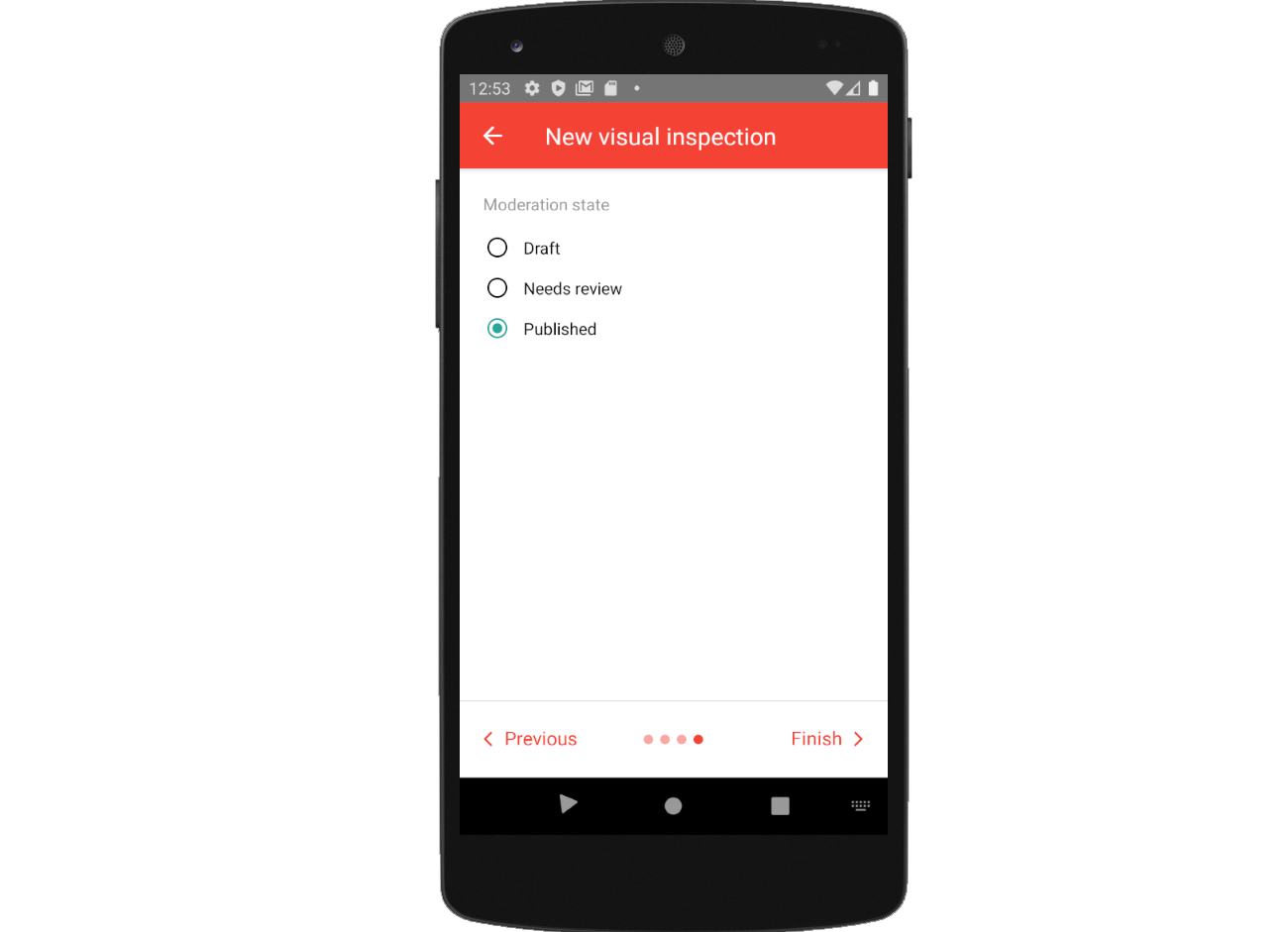

An essential element to digitize visual inspections is the use of an application or app to be able to collect data directly on a tablet or cell phone. Thus, the inspector can access the application instead of preparing his sheet or form of notes. Using the application, the maintenance department saves resources to digitize the inspections compared to digitizing the notes.

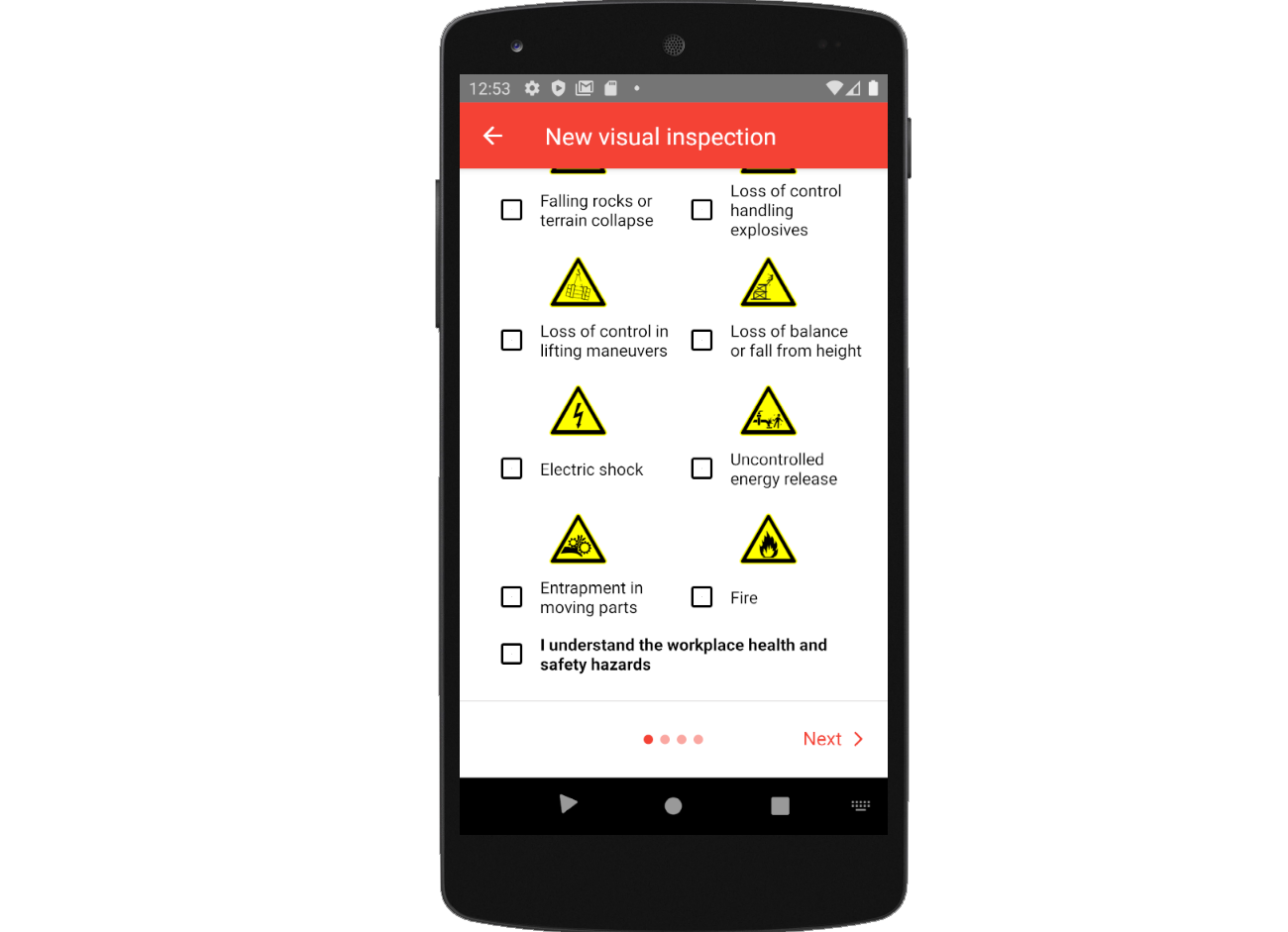

However, the application serves to collect data and faults. It also informs the inspector of the dangers to which it is exposed as determined in the risk assessment.

Power-MI has its visual inspection application fully integrated with the platform. That is, the settings made in Power-MI are automatically synchronized with the application. In the same way, the data collected is automatically downloaded to the platform.

The main features of the Power-MI visual inspection application are:

- Automatic configuration synchronization to the tablet or cell phone without the need to physically connect the devices.

- Automatic download of data, faults, photos, diagnoses, comments and recommendations to the Power-MI platform.

- Offline data collection, you do not need to be connected to the Internet to do the inspections.

- Notice of occupational hazards for the inspector at the time of visual inspection.

- Parameter entry with an automatic on-site evaluation of warning and alarm levels for the inspector.

- Quick execution of inspection guidelines with the possibility of adding comments and/or photos directly with the tablet or cell phone camera.

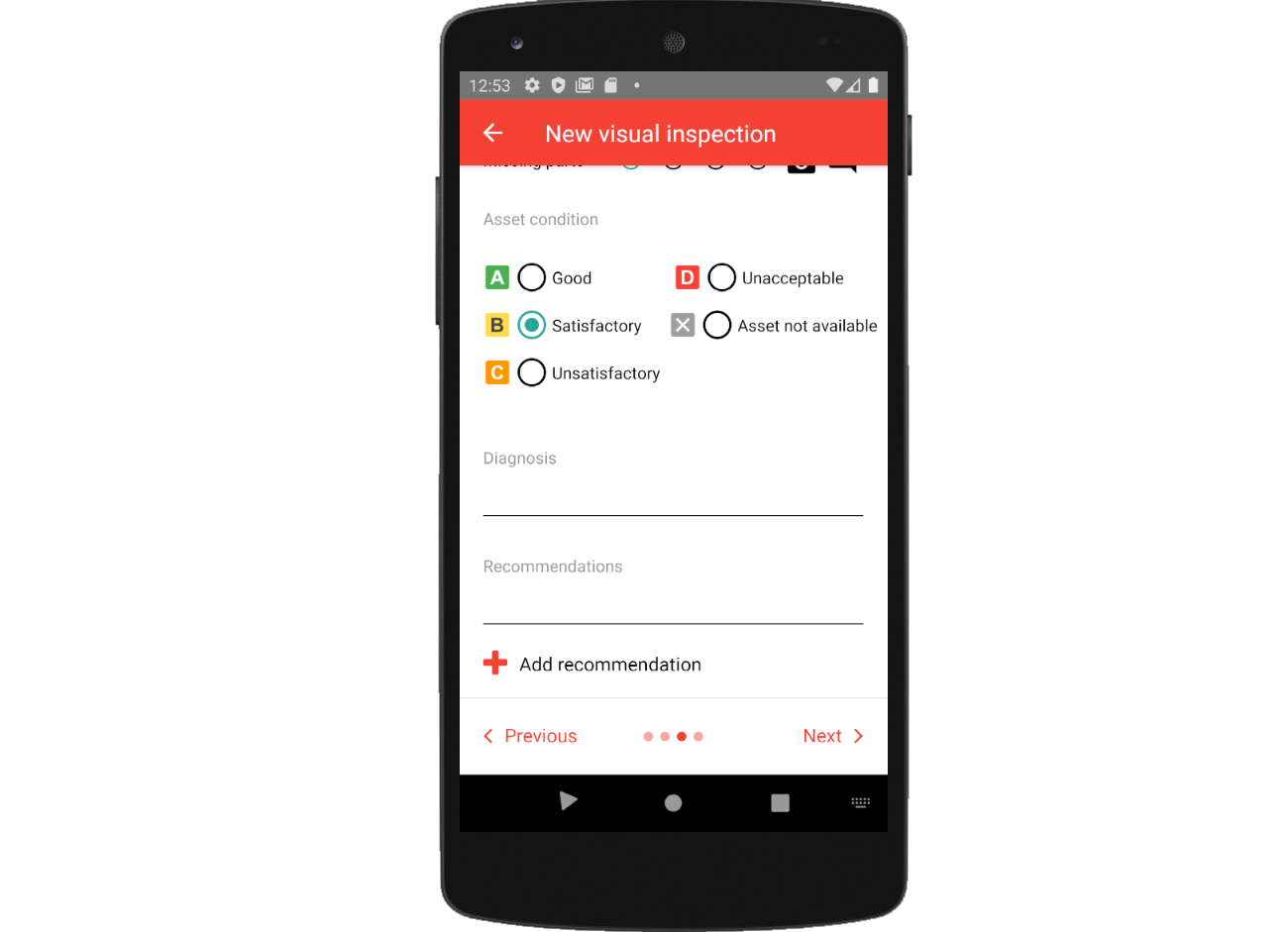

- Quick assessment of asset status.

- Diagnostic and recommendation entry.

- Automatic creation of work orders for the maintenance department.

- Automatic generation of visual inspection reports in Power-MI, downloadable in PDF format.