An electrical connection is faulty when the current flow is not continuous and generates dissipated losses in the form of heat.

Causes

The most common causes of poor connection detectable by visual inspection are:

- Poor selection of electrical connectors.

- Wear of the electrical connector material.

- Bad tightening of bolts or screws of the electrical connector.

- Cable splicing without electrical connector or solder.

- Bad sealing of connectors.

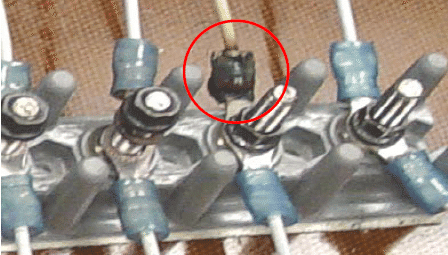

- Bad assembly or bad crimp.

- Use of incompatible materials.

- Corrosive environments.

- Impacts.

- Bad handling of electrical cables.

Cases

Through visual inspections the most common cases of faulty connection that are diagnosed are:

- Connections or terminals in electrical power panels.

- Electrical connection box in electric motors.

- Connections in power lines and transformers.

Diagnosis

Detection of faulty electrical connection in visual inspections is by direct observation of the connector or junction in bad condition, by abnormal noise, by temperature measurement (non-contact) on the connection or by measurement of abnormal current.