Lubrication Management Application for Efficient Machinery Maintenance

Optimize your lubrication processes to enhance equipment performance

Proper lubrication is essential for maintaining the health and efficiency of industrial machinery. Ineffective lubrication management can lead to increased wear, unexpected downtime, and higher maintenance costs. Power-MI's Lubrication Management Application is specifically designed to streamline your lubrication tasks, ensuring every component receives the right lubricant at the right time. By effectively managing lubrication schedules and tasks, you can extend equipment lifespan, improve operational efficiency, and reduce maintenance costs.

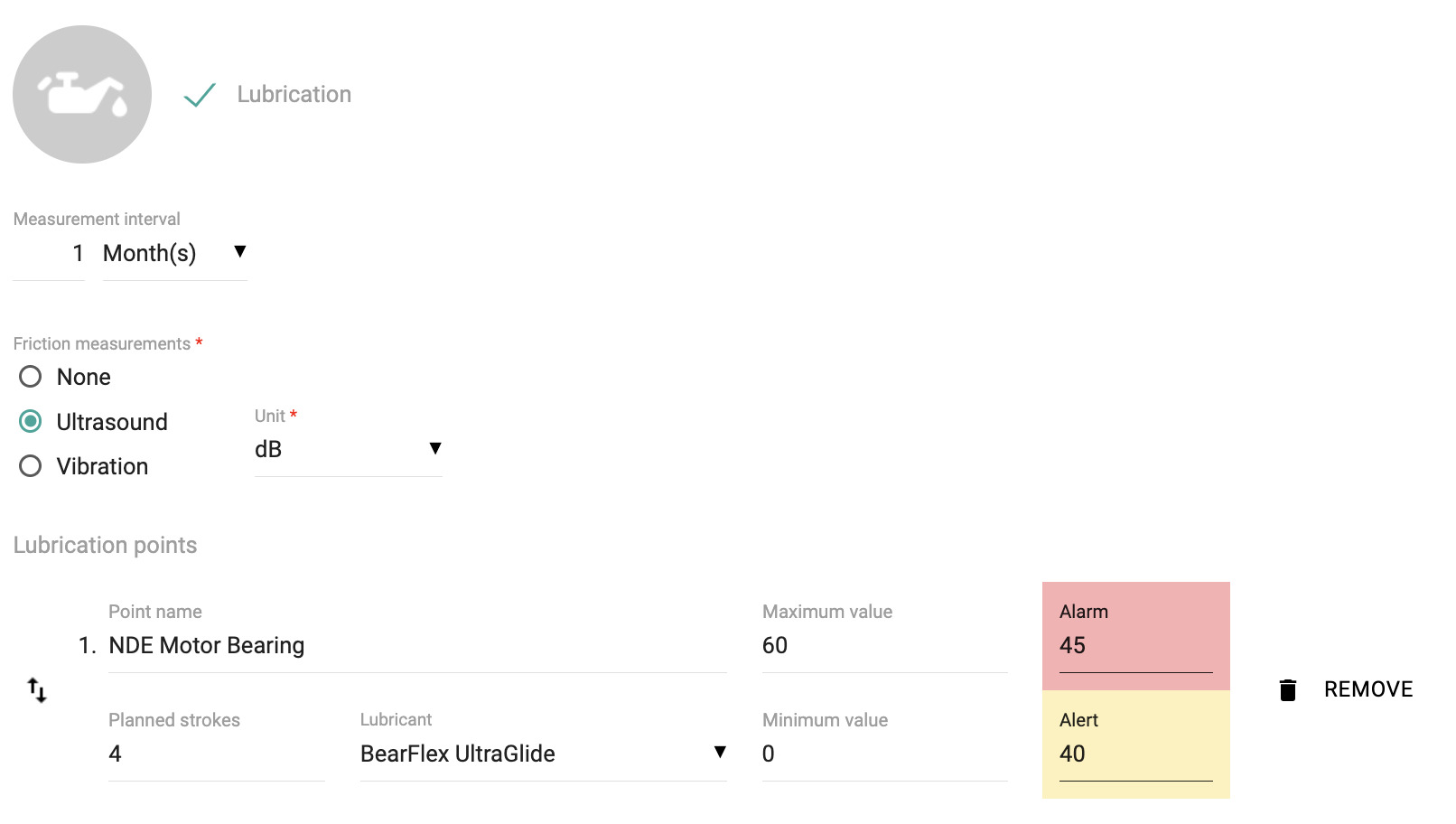

[1] Configure your lubrication plans with Power-MI

Set up lubrication tasks based on schedule or condition

Design your lubrication plans by configuring tasks that are triggered either on a regular schedule or based on equipment condition. This flexibility allows you to optimize lubrication intervals, ensuring machinery is serviced when needed without unnecessary maintenance.

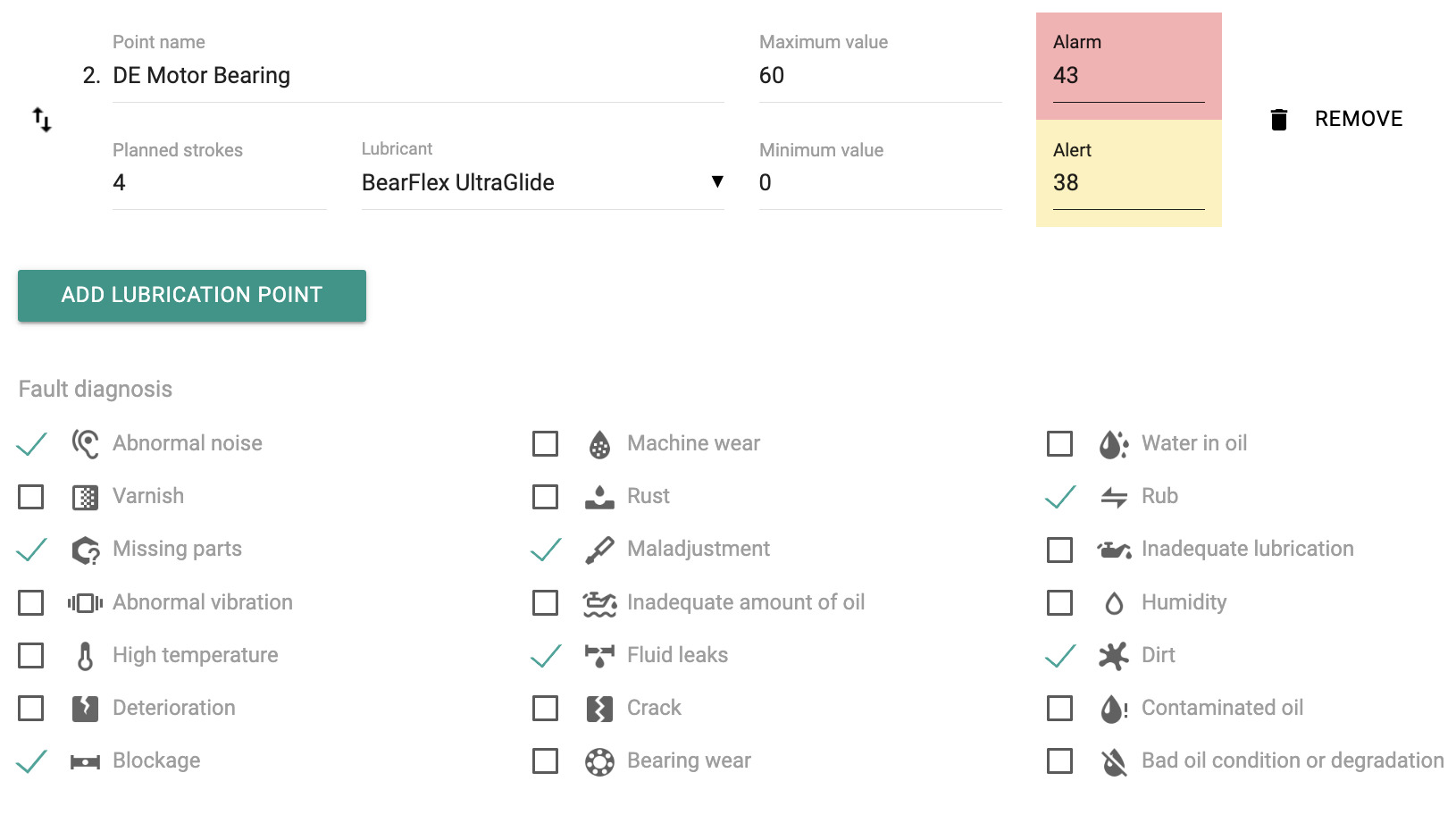

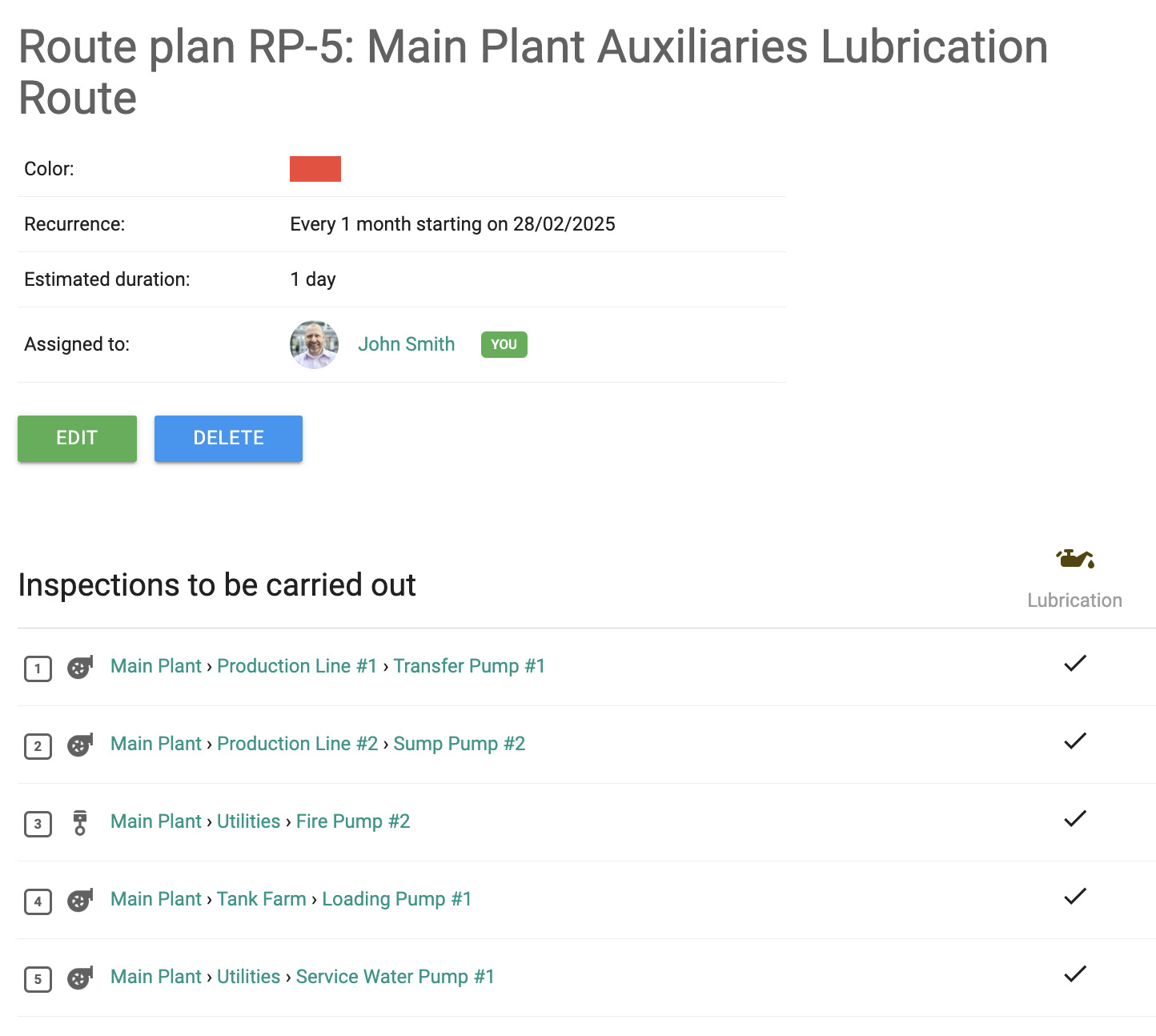

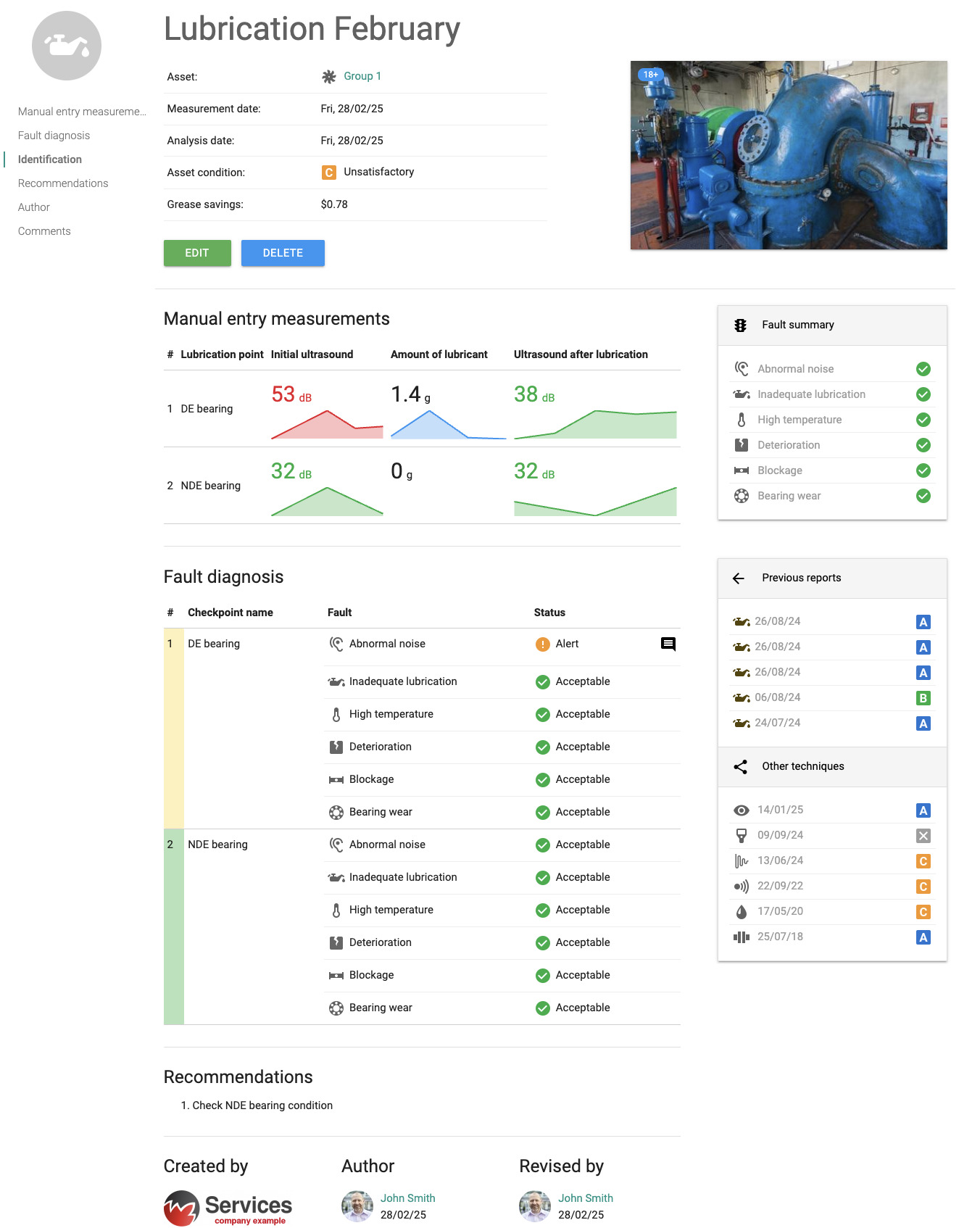

Define lubrication points and checklist

Specify every lubrication point on your equipment with detailed instructions, including lubricant type, application method, and quantity. By providing precise guidelines, you ensure that technicians perform lubrication tasks correctly every time.

Create efficient lubrication routes and calendars

Organize lubrication tasks into optimized routes and schedules, improving technician productivity and ensuring no lubrication point is overlooked. Assign tasks to team members and manage calendars directly within Power-MI.

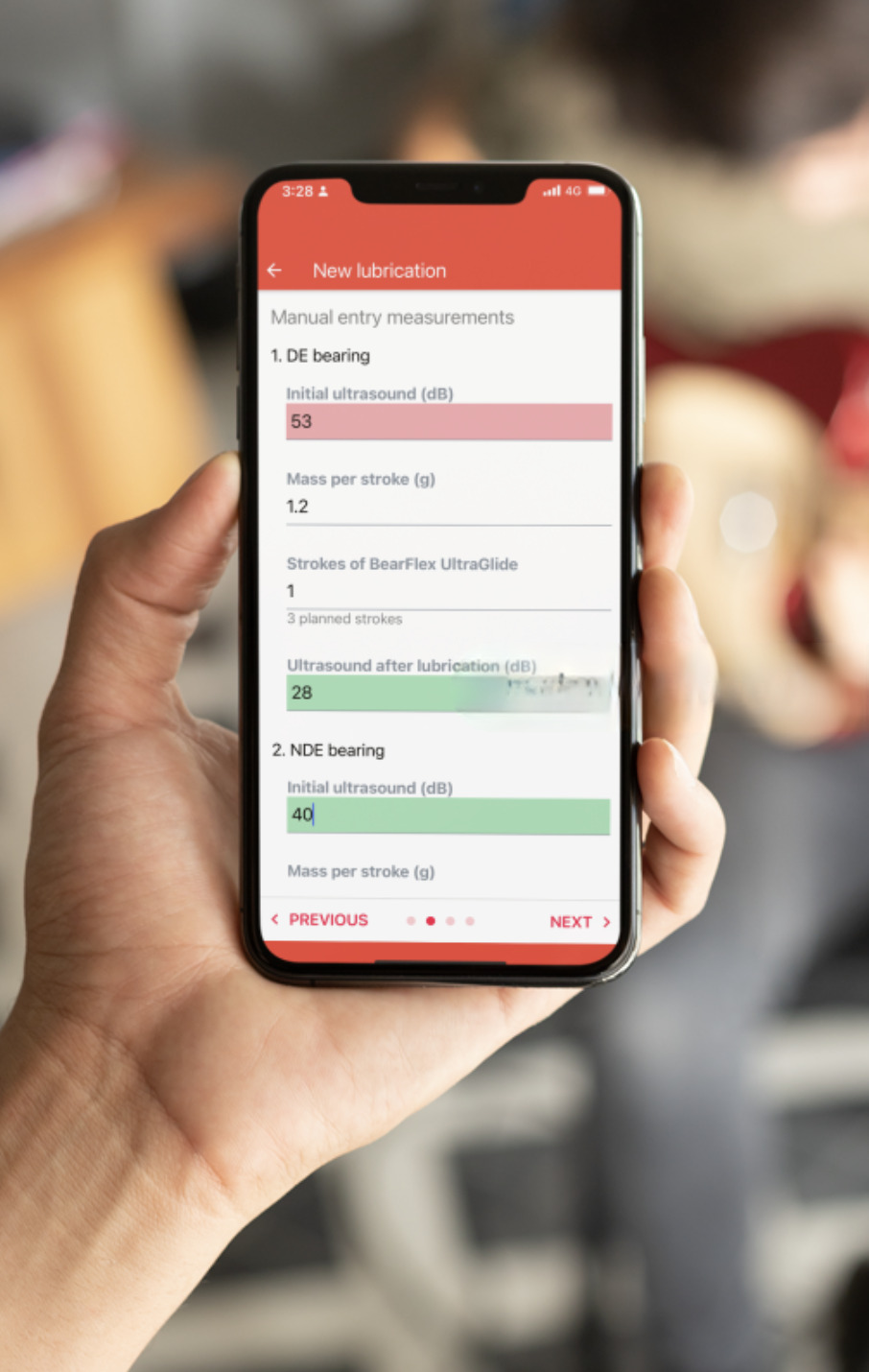

[2] Execute lubrication tasks with the mobile app

Power-MI synchronizes in real-time with our mobile application, enhancing the efficiency of lubrication activities.

User-friendly interface for quick data entry, mobile lubrication app for Android and iOS, and the ability to capture anomalies and field data ensure that technicians can record lubrication tasks accurately and efficiently.

[3] Integrate lubrication management into your maintenance strategy

Seamlessly incorporate lubrication management into your overall maintenance plan with Power-MI's advanced features.

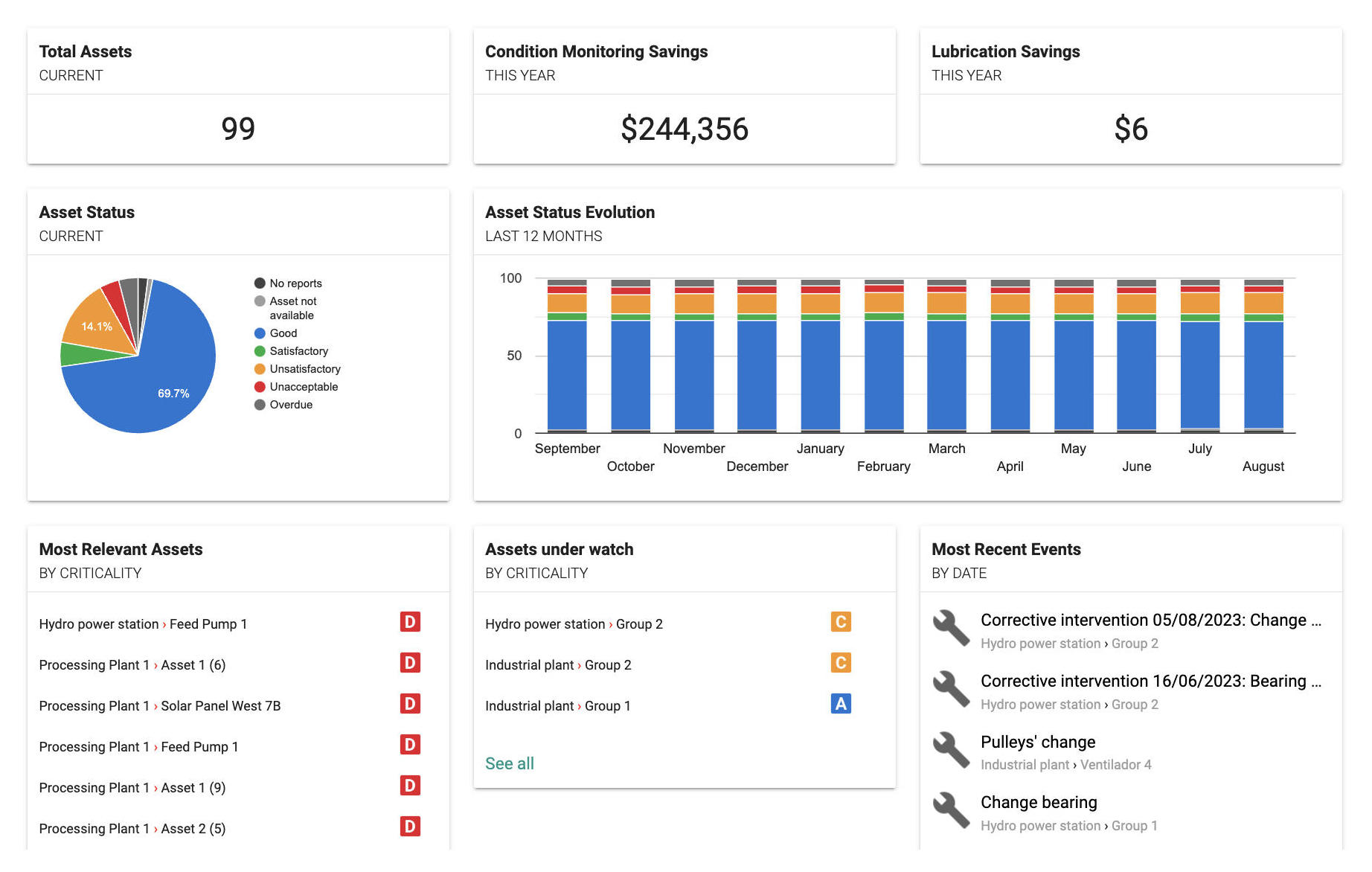

Automatic reporting and analytics

Simplify your reporting process with automatic generation of detailed lubrication reports. Track lubricant usage, task completion, and any anomalies detected for valuable insights.

Standardized procedures and documentation

Maintain consistency across all lubrication activities with standardized procedures and documentation, ensuring every task is performed correctly.

Real-time KPIs for lubrication management

Monitor key performance indicators in real-time, such as task completion rates, lubricant consumption, and equipment performance metrics.

Integration with existing maintenance systems

Integrate lubrication data seamlessly with your current CMMS or ERP systems via API for cohesive workflows and centralized data management.

Benefits of managing lubrication with Power-MI

-

done

Enhanced equipment reliability and uptime

Proper lubrication reduces wear and prevents failures, resulting in increased equipment reliability and minimized downtime.

-

done

Cost savings with condition-based lubrication

Quantify cost savings by optimizing lubrication intervals, reducing unnecessary maintenance and lowering overall costs.

-

done

Increased productivity with streamlined processes

Simplified workflows allow technicians to accomplish more in less time.

-

done

Accurate execution every time

Ensure correct lubricant application and adherence to procedures, minimizing errors.

-

done

Comprehensive reporting and insights

Access detailed analytics to monitor lubrication activities and drive continuous improvement.

-

done

Seamless integration and workflow

Integrate lubrication management with existing systems for unified maintenance operations.

Get started with Power-MI Lubrication Management Application