Is Your Maintenance Program Missing a Structured Lubrication Strategy?

Transform Your Lubrication Practices with Lubrication-PM

Adopt a structured, data-driven lubrication management strategy that integrates seamlessly into your predictive maintenance program, dramatically improving reliability and efficiency.

- Reduce lubricant consumption by up to 30% by applying precise lubrication volumes.

- Enhance machinery reliability, extending asset lifespan and reducing unplanned downtime.

- Lower maintenance costs by optimizing lubrication tasks and technician productivity.

- Eliminate manual paperwork with real-time digital documentation and reporting.

Do You Recognize These Lubrication Challenges?

Traditional, manual lubrication processes often fail due to:

- Unstructured lubrication schedules causing over- or under-lubrication.

- Lack of traceability and inconsistent lubrication records.

- Inefficient lubrication routes, wasting technician hours and resources.

- Difficulty justifying lubrication costs and benefits to management.

Lubrication-PM replaces these outdated practices with a structured, data-driven solution, delivering measurable results.

Introducing Lubrication-PM: Structured, Integrated, Effective

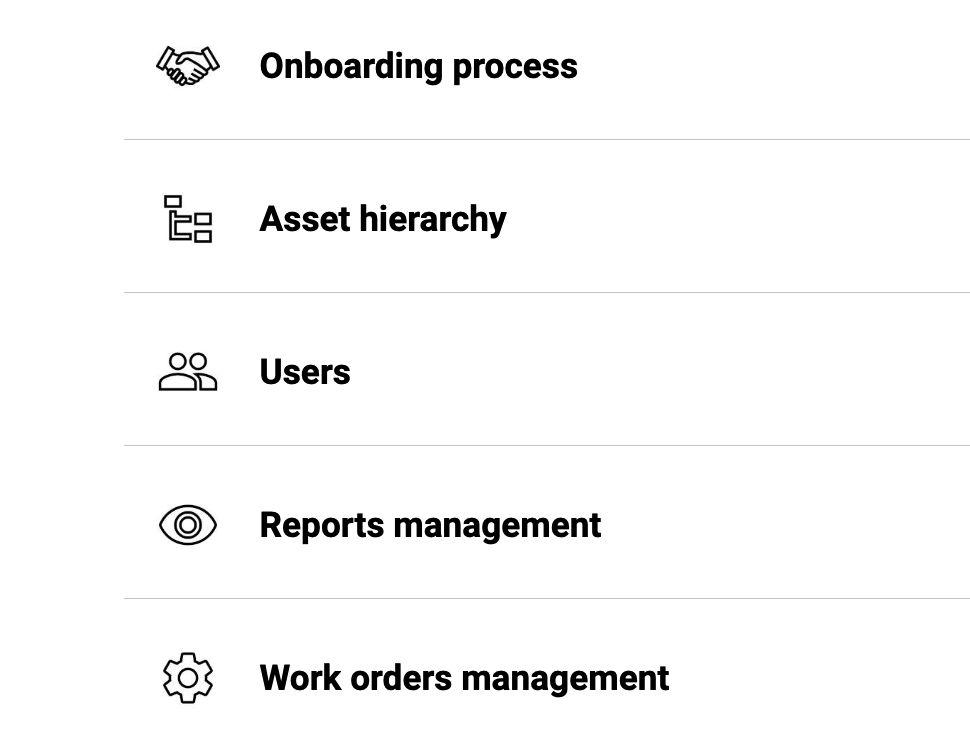

Lubrication-PM is a turnkey lubrication management service built upon the Power-MI platform, blending condition-based and schedule-based lubrication techniques tailored to your industrial assets.

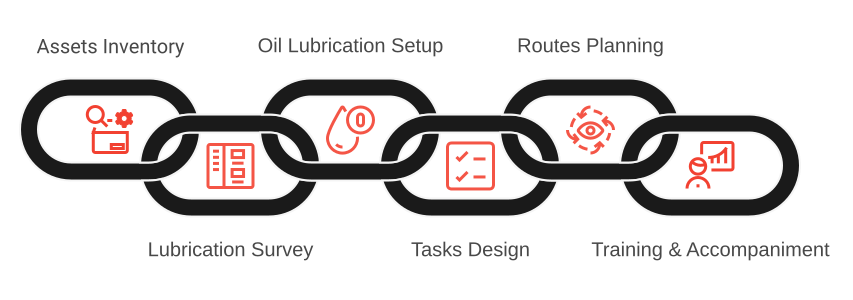

How Lubrication-PM Works:

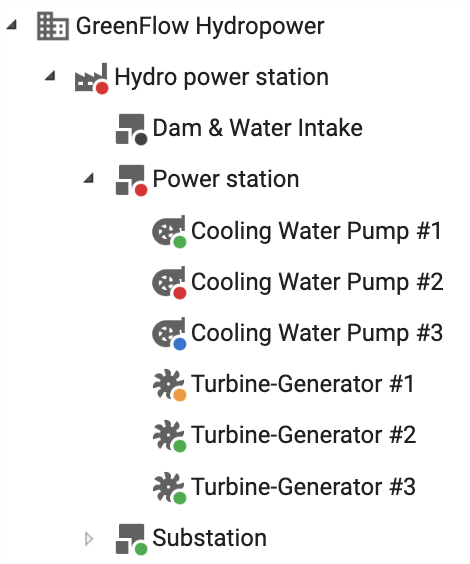

1. Assets Inventory

Detailed digital inventory of machinery assets and lubrication points, creating a robust lubrication foundation.

2. Lubrication Survey

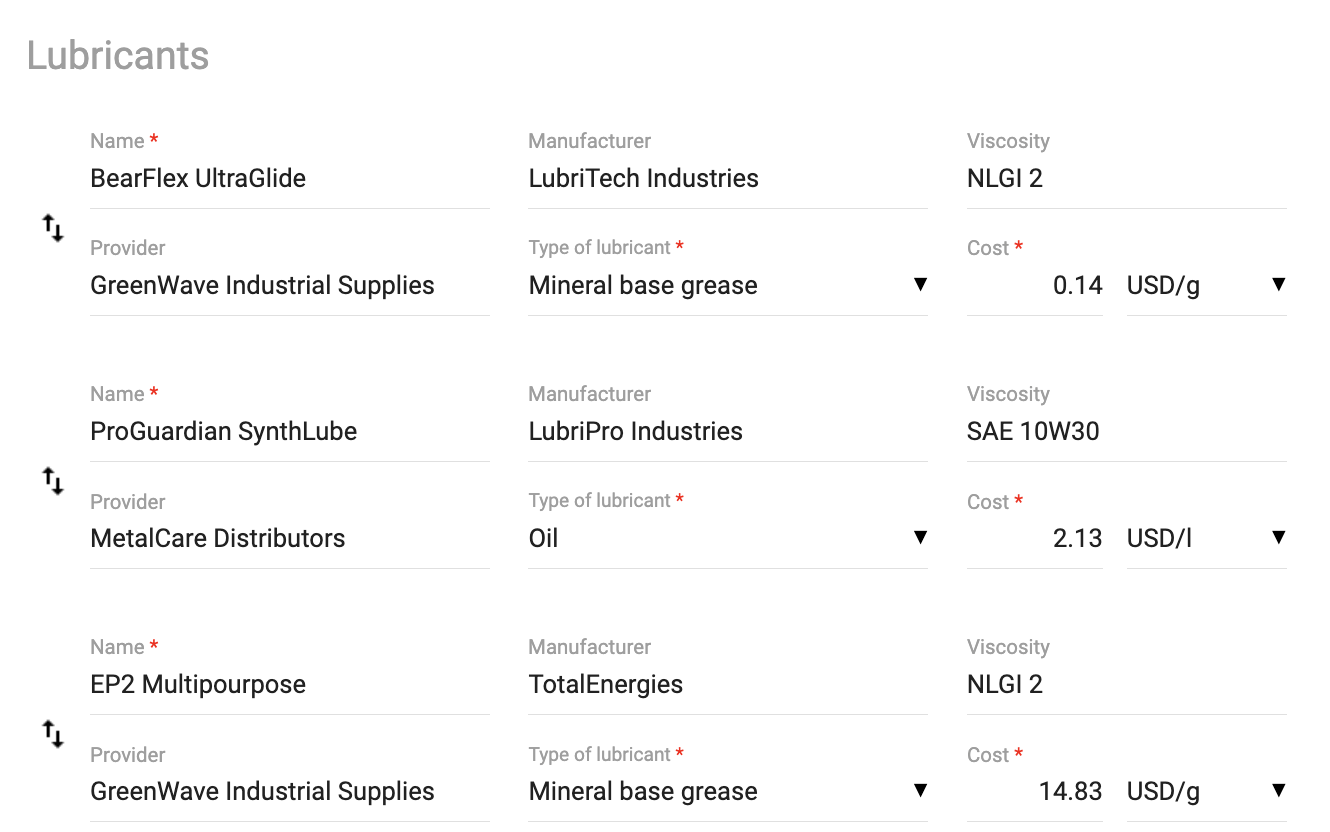

Comprehensive assessment of lubrication points, lubricant types, and precise quantities based on OEM recommendations and operational conditions.

3. Lubrication Setup

Selection and setup of optimal lubricants for specific asset conditions, ensuring maximum performance and reduced consumption.

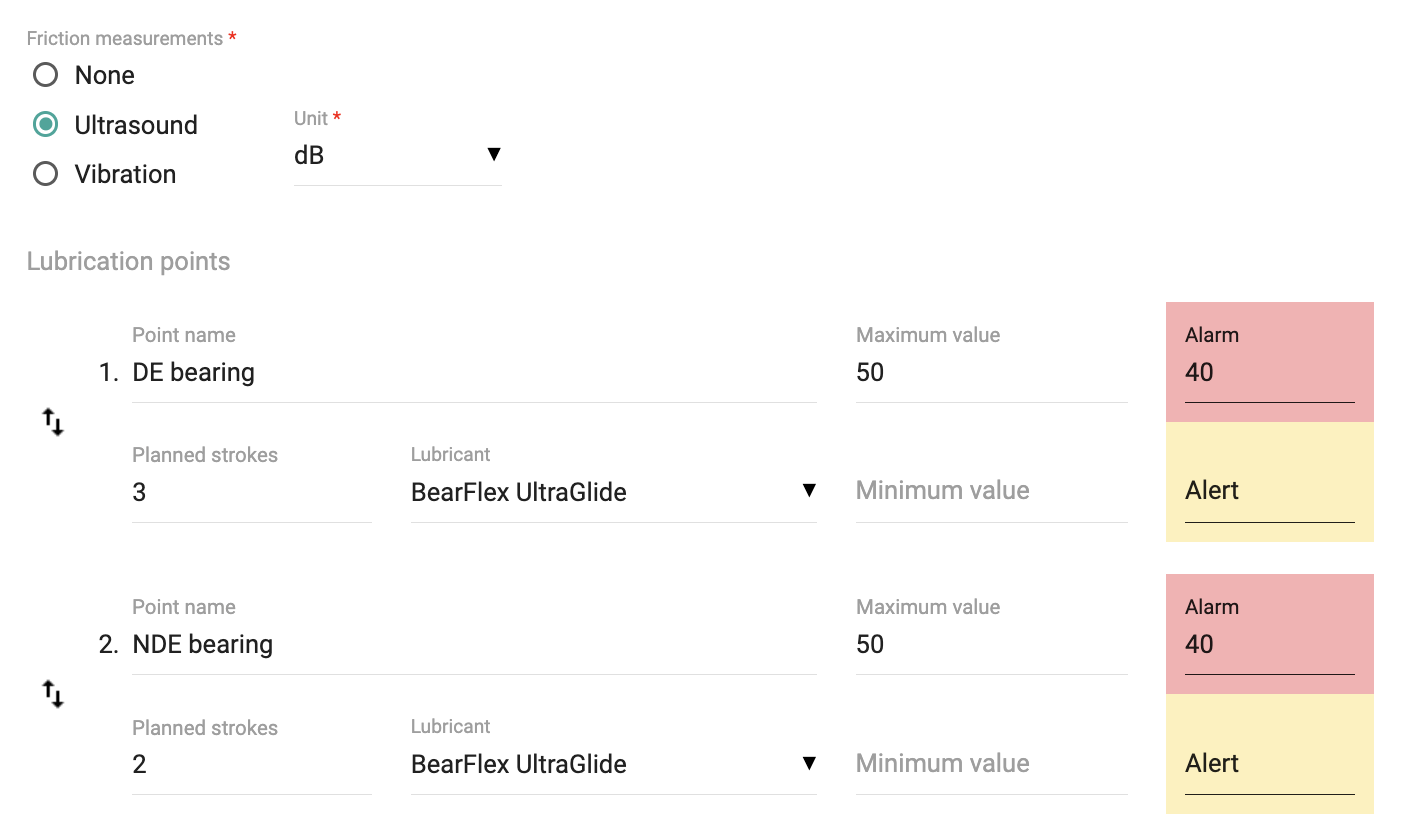

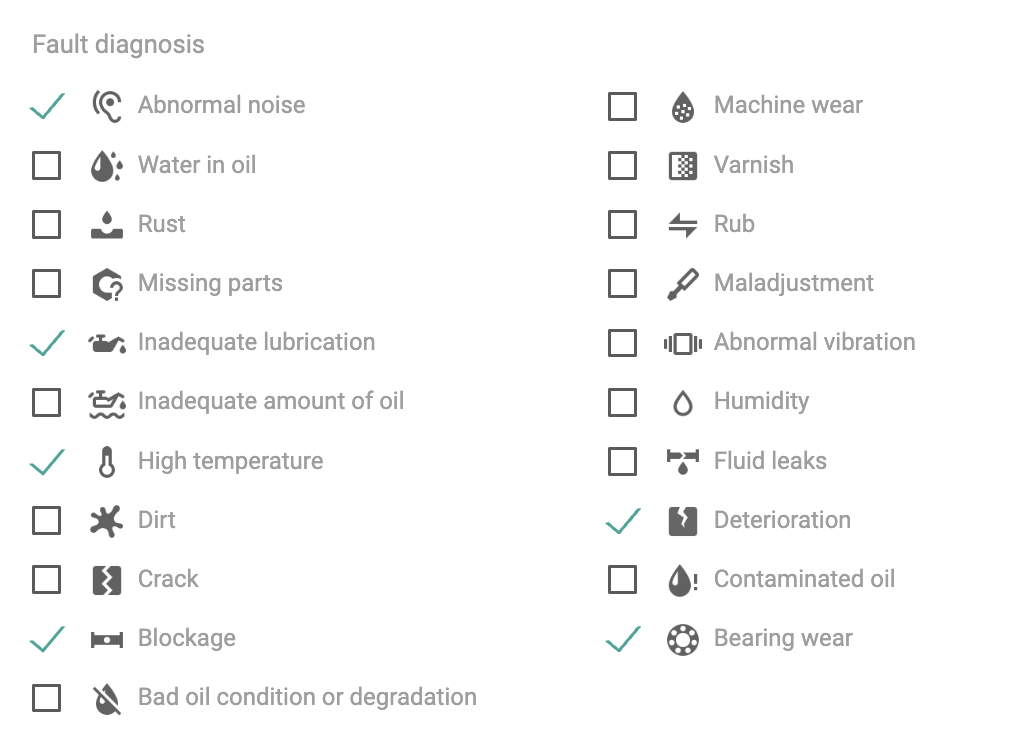

4. Tasks Design

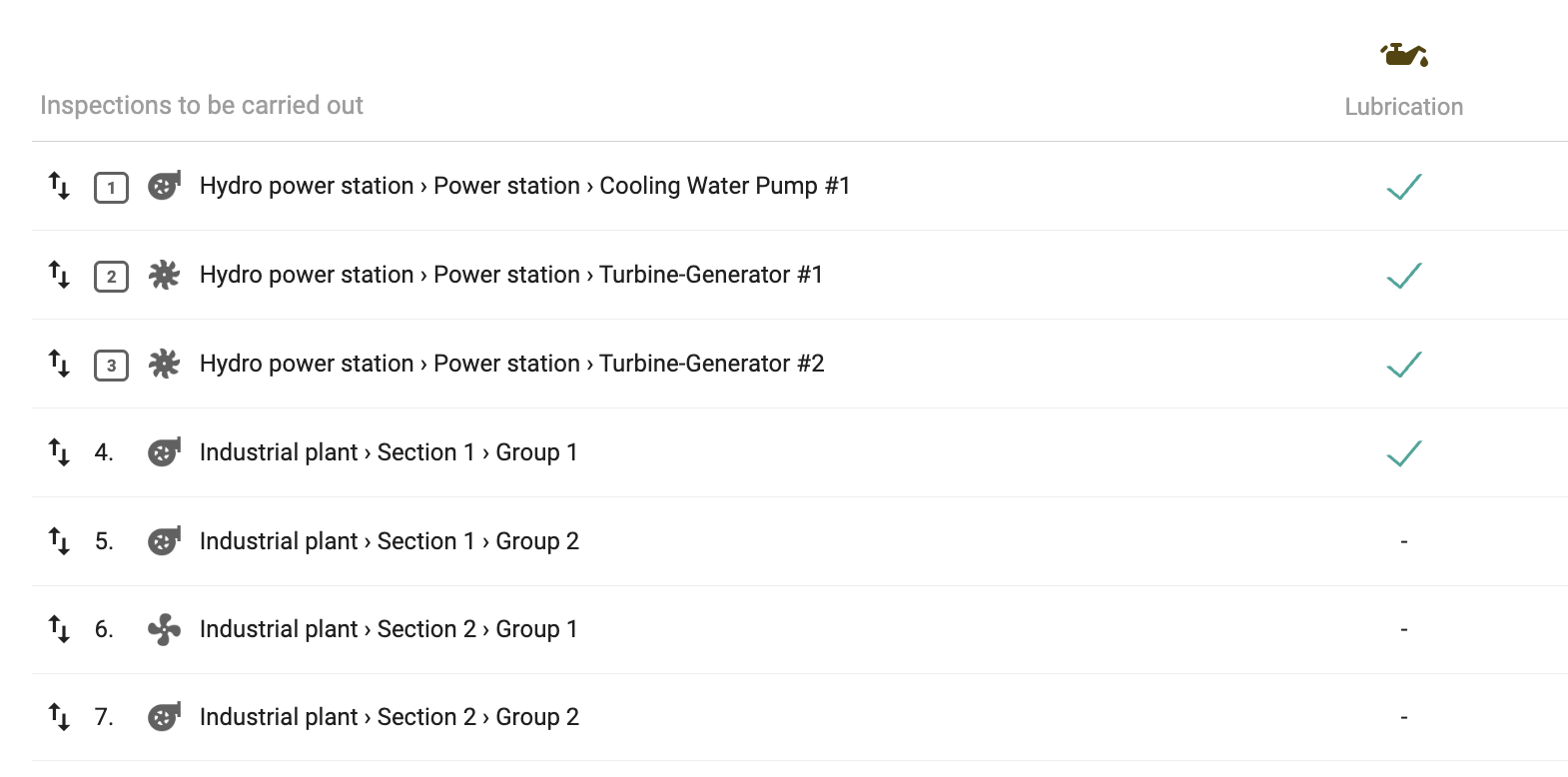

Creation of standardized digital checklists and procedures, integrating seamlessly into technician workflows for consistent results.

5. Routes Planning

Advanced algorithms optimize lubrication routes, significantly reducing technician travel time and missed lubrication tasks.

6. Training & Accompaniment

Complete training and two-week onsite accompaniment ensuring your team is fully proficient and confident using the digital lubrication system.

Why Choose Lubrication-PM?

| Aspect | Traditional Lubrication | Lubrication-PM |

|---|---|---|

| Lubrication Efficiency | Inconsistent, manual methods | Optimized, algorithm-driven |

| Lubricant Usage | Often excessive, wasteful | Precisely calculated, up to 30% less |

| Task Documentation | Paper-based, error-prone, sometimes non-existent | Digital, instant, and reliable |

| Integration with Maintenance | Minimal or none | Fully integrated with PdM workflows |

| Reporting & Analysis | Slow, unclear ROI | Real-time data, measurable ROI |

Trusted by Industry Leaders

Clear, Measurable ROI with Lubrication-PM

Lubrication-PM provides immediate financial benefits:

- Up to 30% reduction in lubricant consumption.

- 20% decrease in downtime, enhancing overall equipment effectiveness.

- 25% improvement in maintenance productivity and resource allocation.

By implementing Lubrication-PM, you achieve tangible financial outcomes that justify your maintenance investments.

Our Commitment: Comprehensive Training and Guaranteed Success

Lubrication-PM is a turnkey service that includes complete implementation, technician training, and two-week on-site accompaniment. Our team ensures that your staff fully understands and confidently executes the lubrication plan before service completion.

Don’t Let Manual Lubrication Practices Limit Your Reliability

Continuing with informal or manual lubrication approaches means ongoing wasted resources, unnecessary downtime, and compromised asset reliability. Shift to a structured, data-driven lubrication strategy today.

Ready to Optimize Your Lubrication Strategy?

Request your personalized demonstration or consultation today:

Start leveraging the full potential of structured, data-driven lubrication with Lubrication-PM.