Is Your Predictive Maintenance Plan Not Showing Results?

Revitalize Your Maintenance Strategy with Planeo-PdM in Just 30 Days

Achieve a customized Predictive Maintenance (PdM) plan specifically designed for your machinery fleet—backed by data, analytics, and practical methodologies.

- Save Over $60,000 compared to traditional consulting.

- Reduce Your Downtime by up to 45% through strategic, targeted maintenance.

- Lower Your Maintenance Costs by at least 25% using data-driven insights.

- Extend Your Asset Life by up to 30%, delaying costly equipment replacements.

Are These Predictive Maintenance Challenges Familiar?

- Your predictive maintenance strategy isn’t clearly defined or lacks measurable financial outcomes.

- You’ve invested in inspection devices (vibration, ultrasound, thermography), yet results remain below expectations.

- External consultants provided complex templates that created more confusion than clarity, stalling your progress.

- You outsourced condition monitoring but never received a clear maintenance plan, leaving your team without actionable guidance.

If you’re facing any of these issues, Planeo-PdM is exactly what you need.

Planeo-PdM: Your Path to a Clear, Actionable Maintenance Plan

Planeo-PdM is a structured, agile, and straightforward service powered by Power-MI’s proprietary AI algorithms and analytics, specifically designed to deliver results within 30 days.

How Planeo-PdM Works:

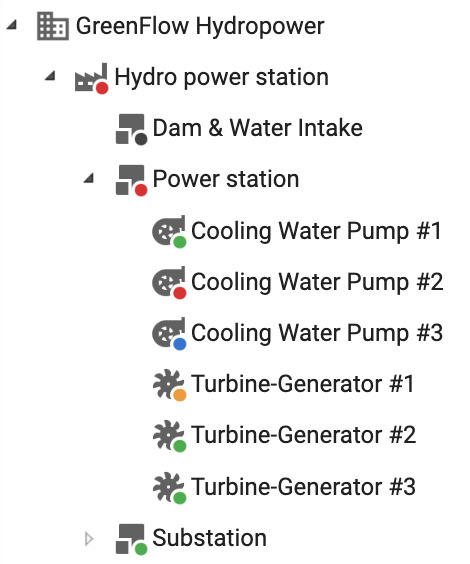

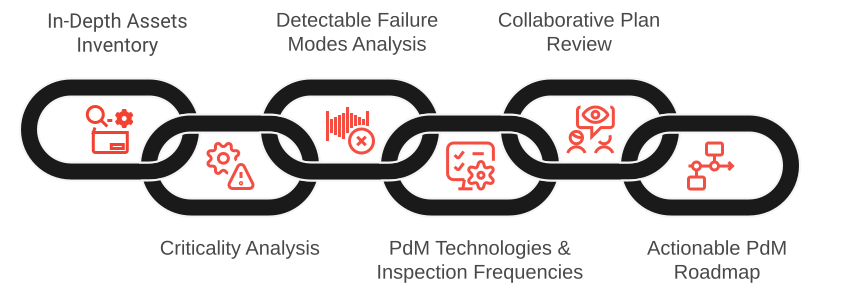

1. In-Depth Asset Inventory

Comprehensive mapping of your equipment to accurately reflect your operational reality.

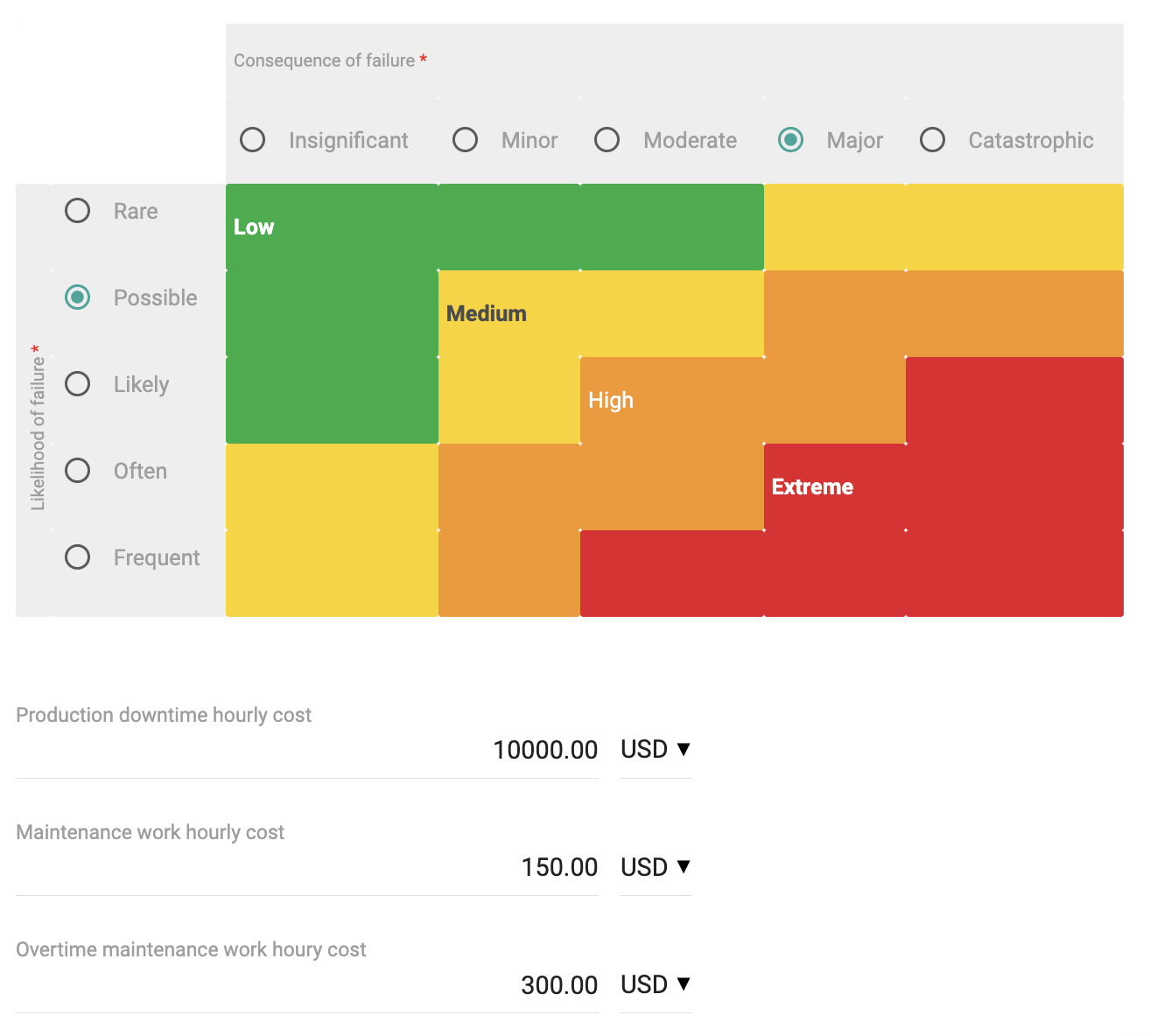

2. Criticality Analysis

Clear prioritization of your most important assets based on risk, operational impact, and potential cost savings.

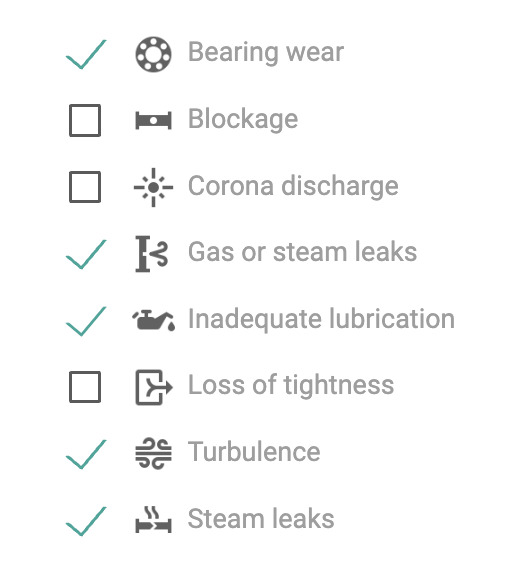

3. Detectable Failure Modes Analysis

Identify precisely what failures are measurable or observable, ensuring targeted monitoring.

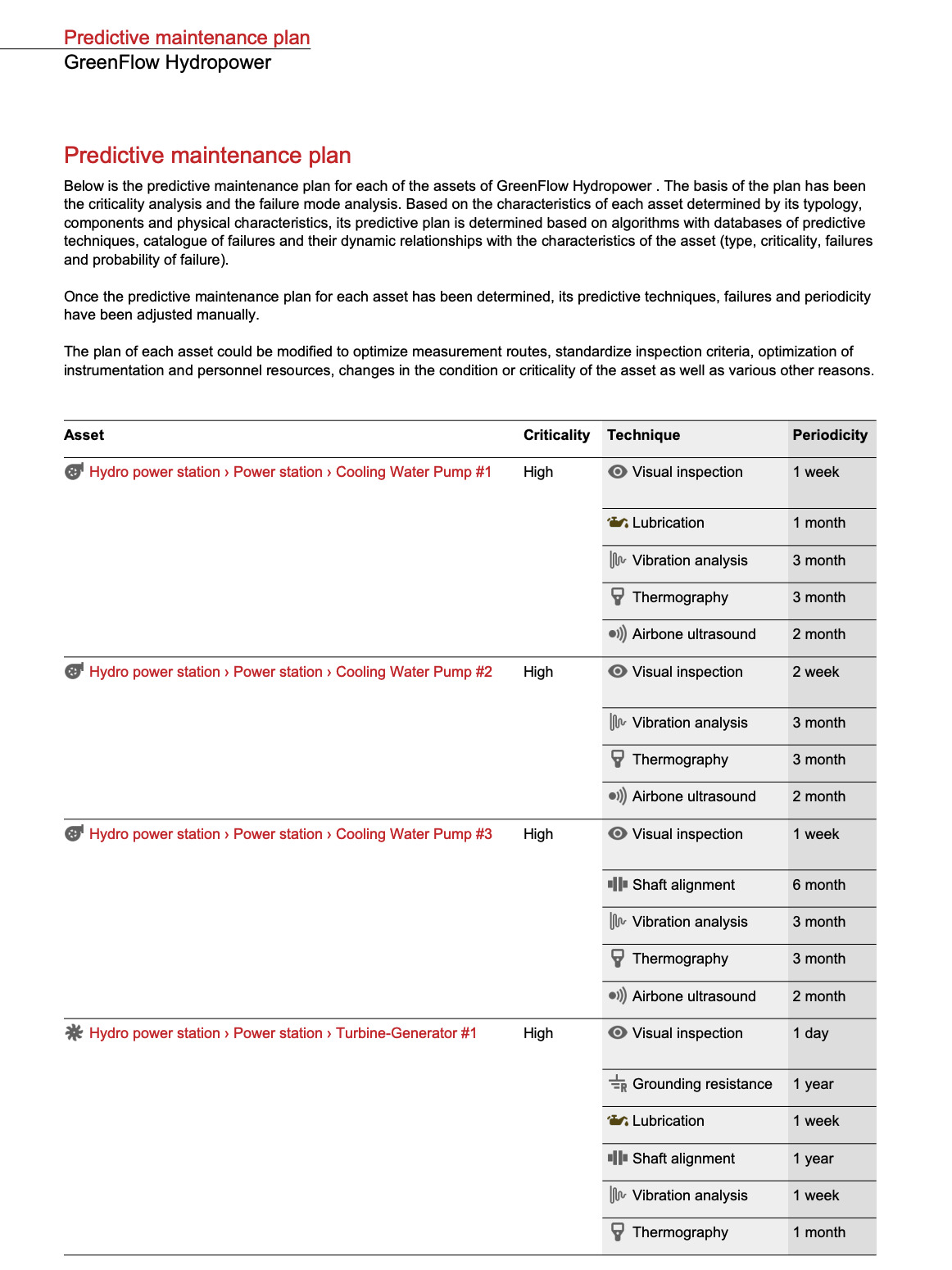

4. PdM Technologies & Inspection Frequencies

Optimal selection of condition-monitoring tools (vibration, ultrasound, thermography, etc.) and inspection schedules, personalized to your assets.

5. Collaborative Plan Review

Continuous engagement with your team to refine and validate the plan, aligning it closely with your operational goals.

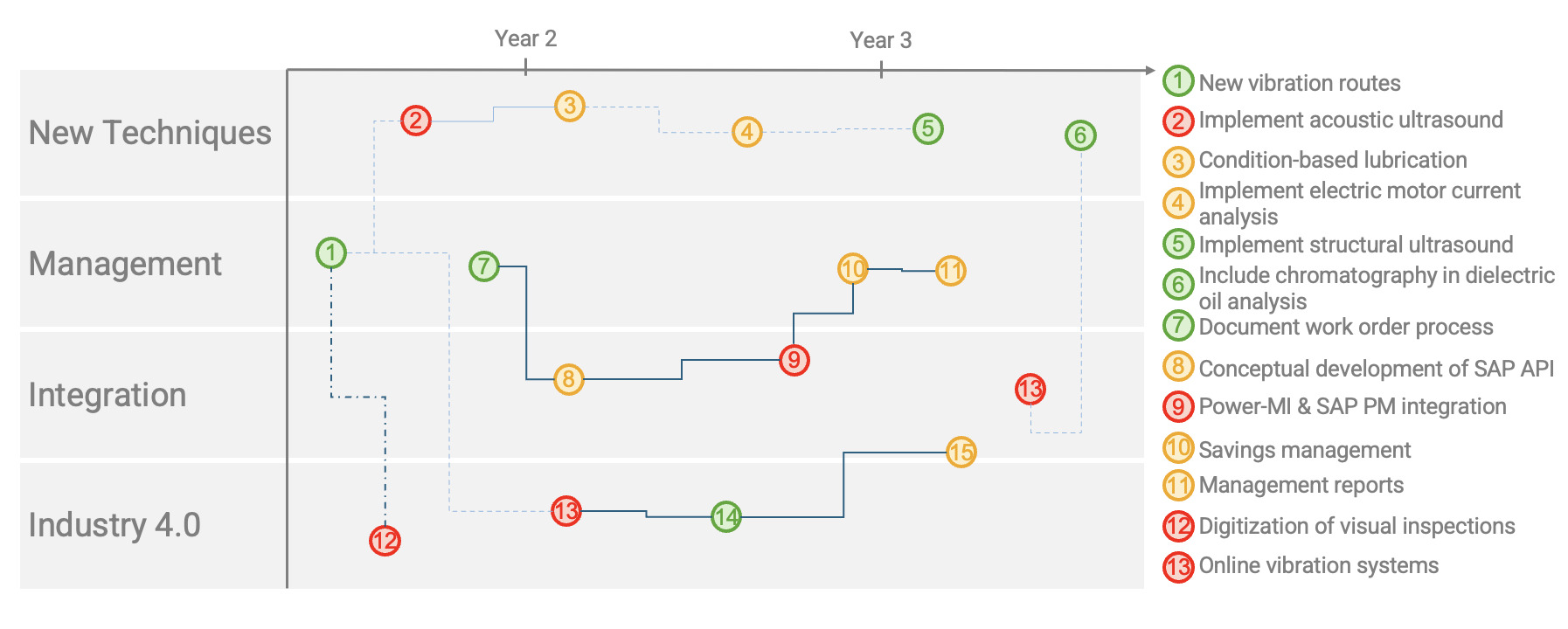

6. Actionable PdM Roadmap

Detailed, prioritized action plan guiding step-by-step implementation.

Why Clients Prefer Planeo-PdM

- Fast Implementation: Complete, actionable plan delivered in 30 days—no lengthy consultancy contracts.

- High ROI: Immediate financial impact through reduced downtime, maintenance costs, and extended asset life.

- Data-Driven Accuracy: Built on proprietary algorithms, analytics, and a structured process rather than generic templates.

- Continuous Support: Dedicated assistance to iterate the plan until you’re fully satisfied, including one year of Power-MI Enterprise platform access.

Trusted By Leading Companies

Clearly See the Financial Impact

ROI from Predictive Maintenance (Industry Benchmarks)

- Up to 45% reduction in unexpected downtime.

- 25% decrease in overall maintenance expenses.

- Asset lifespan extended by 30%, significantly reducing capital expenditure.

ROI from Choosing Planeo-PdM (versus alternatives)

| Scenario | Consulting Firm | Planeo-PdM |

|---|---|---|

| Speed of Implementation | 3-12 months | 30 Days |

| Costs | $80,000+ | Less than 30% |

| Actionable Results | Generic Plans | Customized |

| Deliverables | PowerPoint and Word templates | Ready to execute plan |

| Software Integration | Limited | 1-year Enterprise Power-MI ready to use |

| Follow-up Support | Limited | Ongoing until satisfied plus 6 months follow-up |

Don't Let Inaction Cost You

Every day without a structured predictive maintenance plan increases your risks:

- Escalating downtime and unplanned maintenance.

- Increased emergency repair costs.

- Shortened asset life leading to early replacement.

Act now to avoid these unnecessary expenses and disruptions.

Ready to Transform Your Predictive Maintenance?

Schedule your personalized demo or consultation now.

Unlock the Full Value of Predictive Maintenance Today.