Tightness is the property of surfaces to keep two separate fluids. Usually one of the fluids is atmospheric air. Tightness is generally associated with pressure or vacuum tanks as well as waterproofing environments against water. When there is an exchange of fluids that should be separated or when the fluid is transferred to or from a tank or reservoir, you have a leakage failure.

Causes

The causes of loss of tightness are similar to those of Leaks since the tightness is lost by fluid leaks. The main causes of leakage detectable by visual inspection are:

- Wear or failure of seal, gasket, or gaskets.

- Defective joints.

- Mishandling of valves and drains.

- Degradation of the material in contact with the fluid.

- Welding fault.

Cases

Through visual inspections the most common cases of leakage that are diagnosed are:

- Pressure or vacuum tanks.

- Containers.

- Soil waterproofing.

- Pipelines.

- Heat exchangers.

Diagnosis

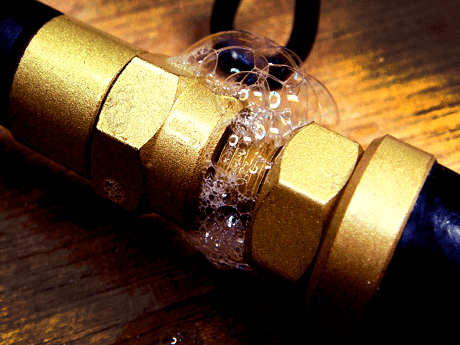

The detection of leakage in visual inspections is through pressure (or vacuum) readings, observation of the leak, abnormal noise, detection of condensed fluid outside its storage place, or the appearance of bubbles.

Points to consider:

- If you want to do tightness tests in visual inspections, make sure they are at specific inspection points and not as general as tank or pipe. Consider doing advanced leak testing outside of the visual inspection path.

- If a leak is detected that affects the tightness of an asset, select tightness as the main failure.

- Consider recommending advanced leak tests to confirm the diagnosis.

- Not all fluid leaks cause loss of tightness.

- Not all pressure variations are due to lack of tightness.