In visual inspections for maintenance, the temperature is the physical quantity that expresses the level of heat of bodies or working fluids. Ambient temperatures are not generally measured.

Causes

The most common causes of high temperature detectable by visual inspection are:

- High friction.

- Poor heat dissipation.

- Over-lubrication.

- Coolant or cooling air blockage or blockage.

- Solar radiation.

- High electric current.

- Improper heat transfer in processes.

Cases

Through visual inspections the most common cases of high temperature that are diagnosed are:

- Shaft misalignment in couplings causing the high temperature in motor bearings and driven element.

- High vibration in bearings.

- Bad lubrication in bearings and gearboxes.

- Over-greasing of bearings causing sliding of rolling elements.

- Dirt in heat exchanger of cooling systems.

- Air filter obstruction in electric motors makes it difficult to cool.

- Working fluid or lubricants with changes in the process.

- Electrical control panels with short circuits.

Diagnosis

The detection of high temperature in visual inspections is by measuring parameters either by portable meters or by permanent temperature probes with data collection in the field. Also by temperature strips adhered to the surface of the inspection point. In less common cases, the high temperature is detected by radiation perceived by the inspector. It is not recommended to check high temperature to touch.

Points to consider:

- If the high temperature is diagnosed by its measurement, it is because an alert or alarm level has been exceeded. See Abnormal process parameters.

- If not, explain the reason for the diagnosis in your report.

- Make sure the type of temperature strip you are using. You may have an instant marker or maximum marker.

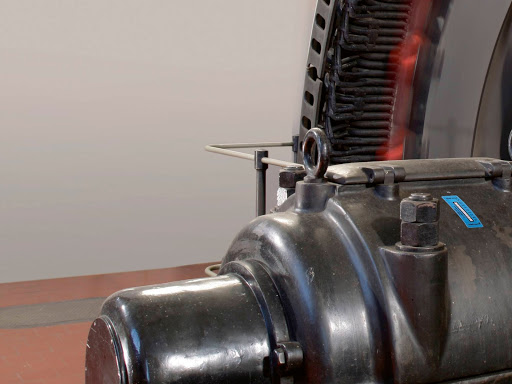

- High temperature can be diagnosed by discoloration. These cases are usually extreme.

- Trying to check the temperature by touch is a bad occupational hazard practice.

cloud_download

cloud_download