Bearings are machine elements with a limited lifespan. Their lifespan depends on multiple factors, ranging from design and manufacturing to installation conditions, maintenance practices, and operating conditions.

Bearings bear the majority of the loads during rotational and reciprocating movements. They are among the most frequently replaced components, often prematurely, causing losses in time, production, and money. In other cases, bearing failures can lead to catastrophic machine damage.

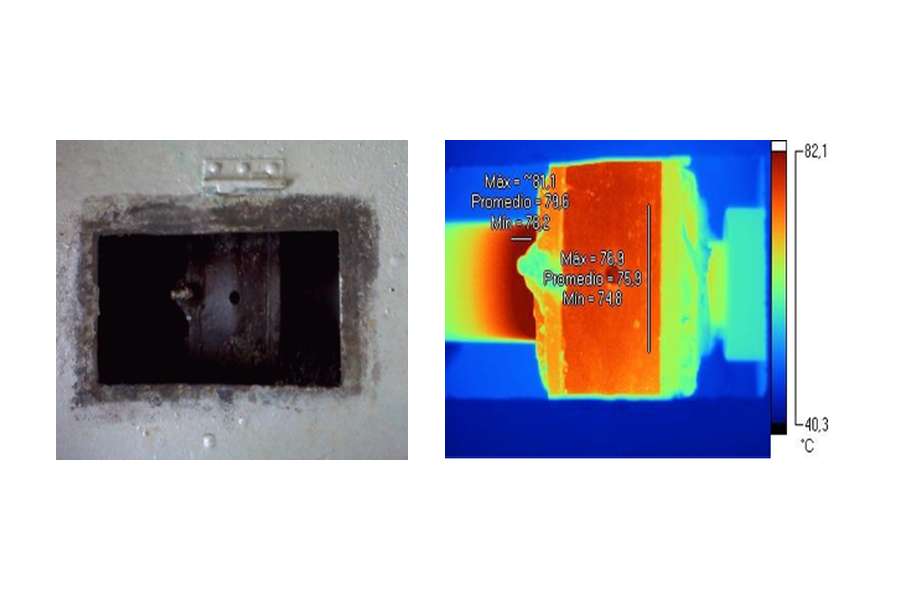

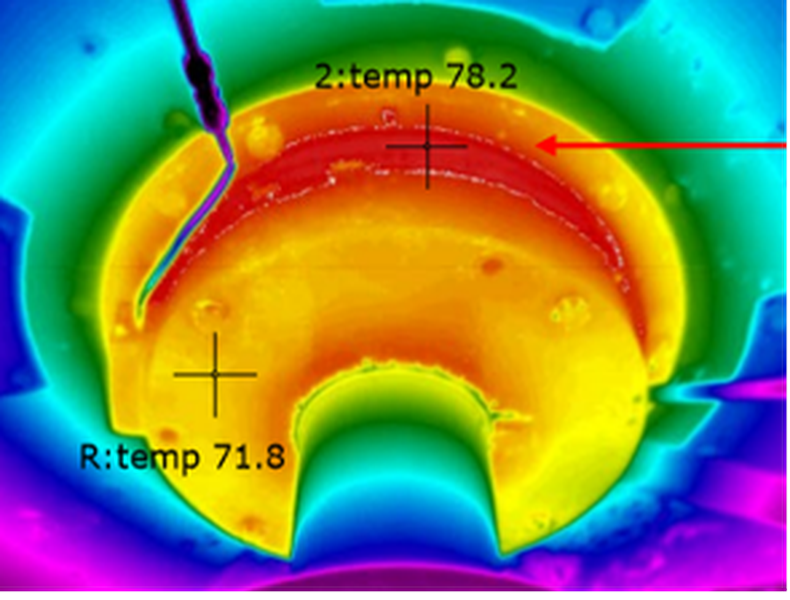

An increase in bearing temperature is an indicator of bearing failure. Rolling element bearings have a normal operating temperature range of 140 to 155 degrees Fahrenheit when installed in pumps. A bearing temperature of 180°F is typically considered an alarm point, and if it reaches 190°F, the pump should be shut down.

If a machine's bearing operates above the optimal temperatures, it is highly likely that:

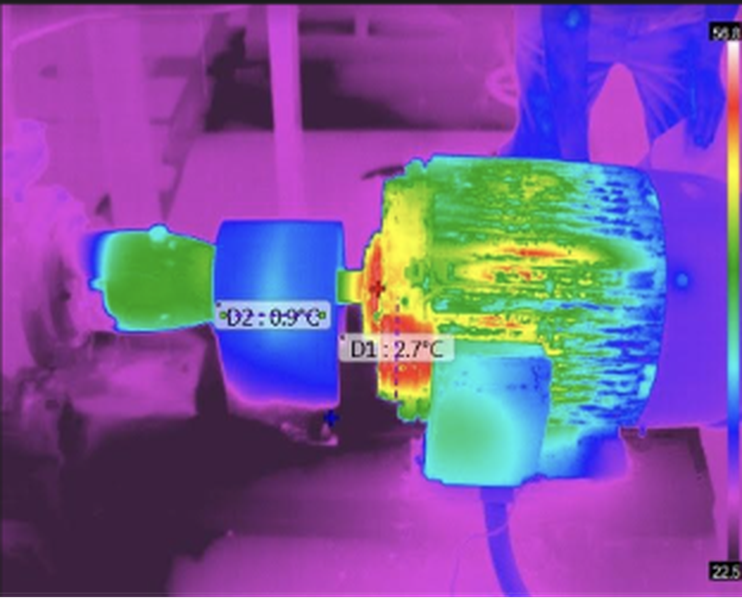

- Misalignment between shafts.

- Incorrect installation, such as shaft or housing misalignment, improper tolerances, or poor surface finish.

- Inadequate lubrication.

- Bearing sealing failure.

Checking the bearing temperature by hand or through the bearing housing is not an effective method for diagnosing the fault.

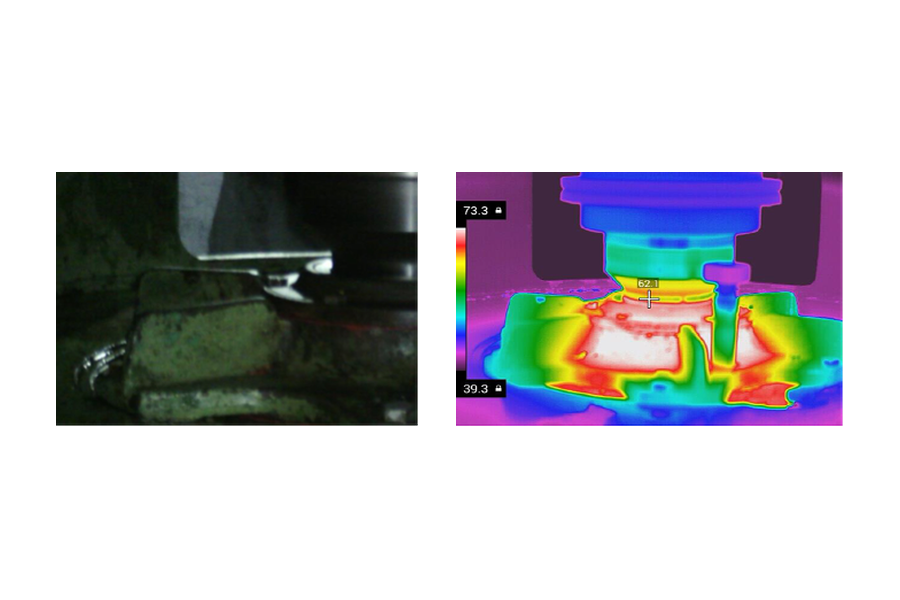

However, infrared thermography is effective in detecting and measuring the bearing operating temperature. It serves as a confirmation of diagnoses made using other predictive technologies such as vibration analysis.