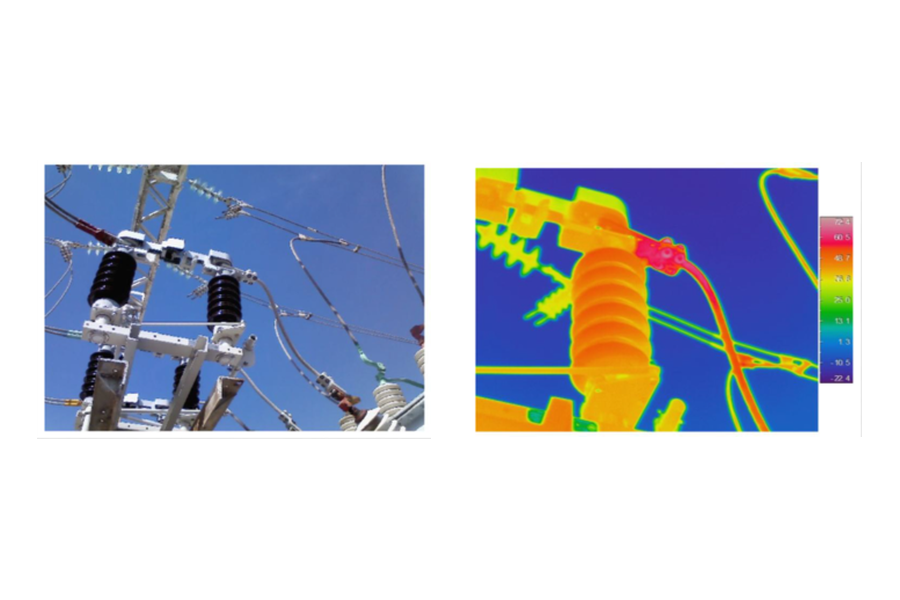

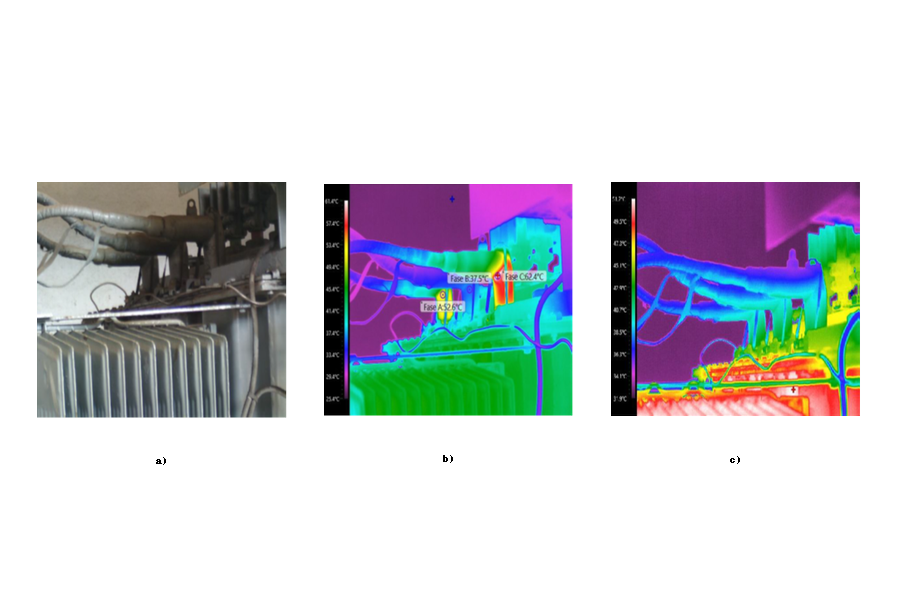

A faulty connection refers to an issue in connecting an electrical component, such as cables or connections in a circuit. This can happen when a connection is not properly secured, tightened, or soldered, leading to interruptions in the transmission of electrical energy. This type of failure can cause problems like fluctuations in electrical current, overheating, and in extreme cases, even short circuits or fires. Infrared thermography is a useful tool to identify these faults, as it can detect abnormal temperature changes in faulty connections, helping technicians locate and address the issues before they cause major damage or hazards.

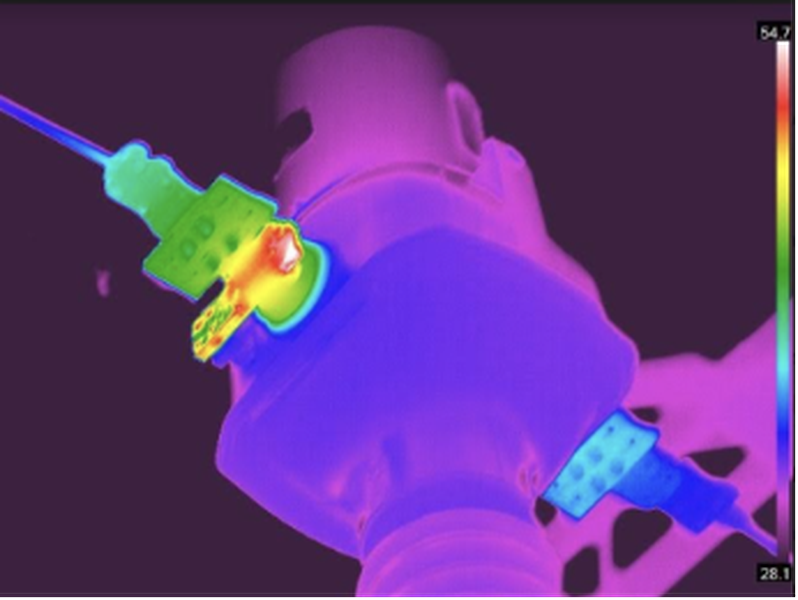

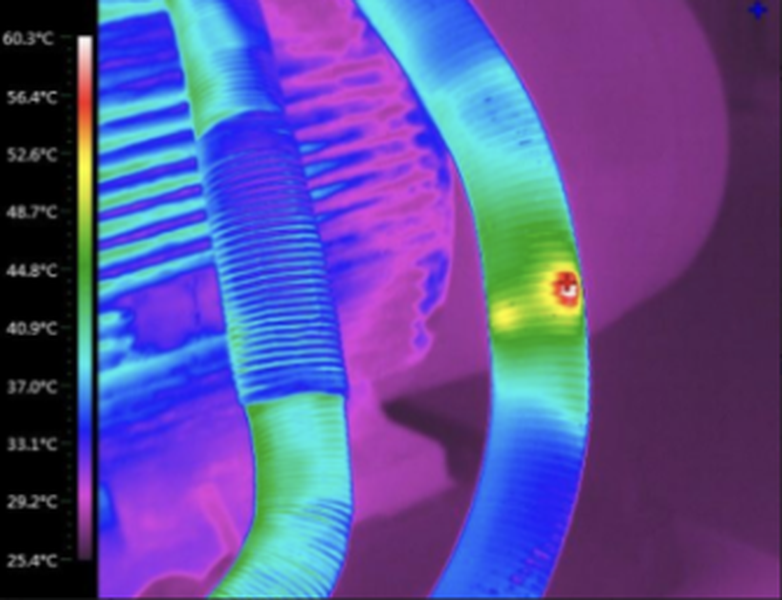

The costs of power transformer bushings typically account for around 4 to 9% of the total installed cost of the equipment. However, the failure of one of these bushings can be catastrophic and lead to the total loss of the transformer, resulting in significant financial losses. Bushings are often the weak link in the chain and also the second leading cause of such failures.