Thermal insulation is a component that must be installed and maintained according to the requirements of each system. Failing to pay proper attention to thermal insulation can result in unnecessarily high energy consumption, increased environmental emissions, temperature losses, efficiency reductions, and economic losses.

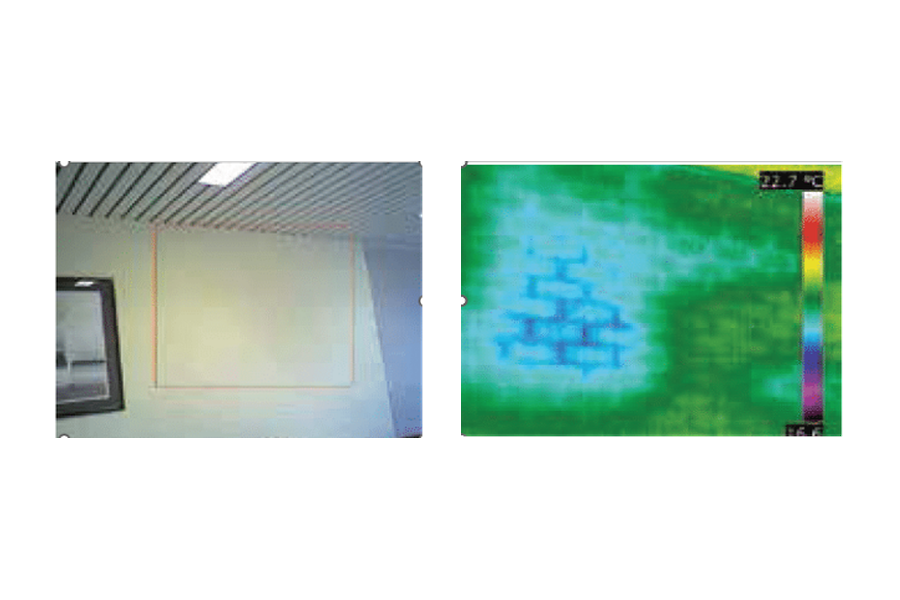

In the following thermogram, we observe a wall with a lack of insulation, the bluish colors denote a colder temperature than the rest of the wall.

Excessive condensation can lead to corrosion and affect buildings, electrical installations, service pipes, and expensive materials. Insufficient thermal insulation can cause vapor leaks and expose personnel in high-risk areas to elevated temperatures, compromising their safety.

For these reasons, thermal insulation must be considered from the correct selection of insulating materials, dimensions, and installation, taking into account thermal bridges' needs, proper fitting to pipe diameters, appropriate thicknesses for working temperatures, ensuring the vapor barrier, and scheduling inspection and correction actions.

Infrared thermography provides predictive information during inspections of thermal insulation systems, and it is the responsibility of Thermograph to contribute to reducing energy losses and preventing harmful emissions to the environment.

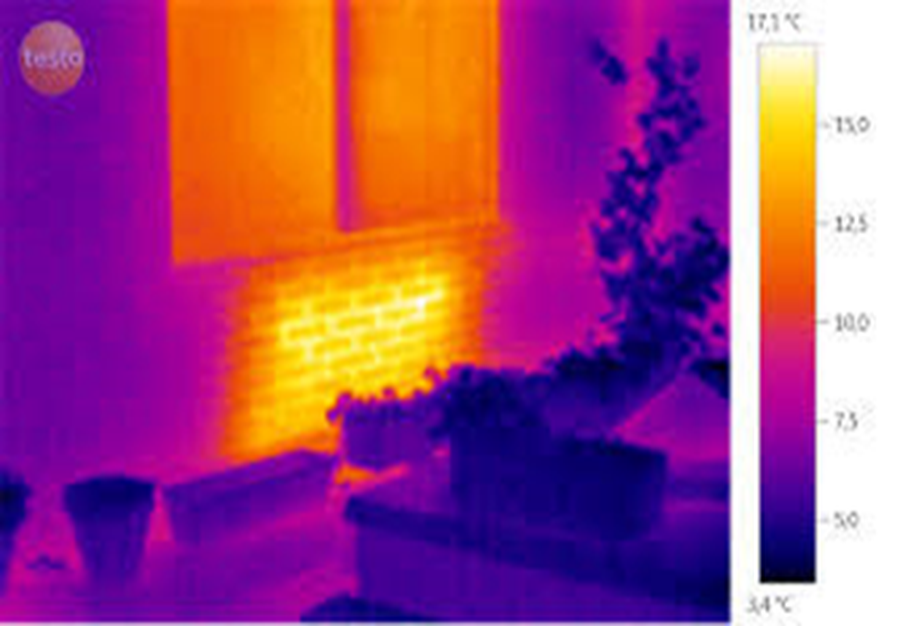

Refrigeration rooms operate 24/7 to maintain low-temperature conditions for food preservation. Due to this, their energy consumption is high, and their proper functioning is vital to avoid increasing the energy bill of these facilities. The thermal image clearly shows poor sealing of the doors and the escape of cold air to the outside, leading to extended system operation hours and reduced lifespan.

Similarly, the same happens with heat losses in heated spaces. These losses can significantly increase electricity bills due to entirely avoidable causes, which can be identified through Infrared thermography.

The ventilation nozzles are designed to propel air, either cold or hot, over long distances and at high speeds. In the thermal image, it can be observed that, in this case, the nozzles' fitting does not fulfill its function, and part of the hot air intended for delivery remains trapped in the false ceiling and does not reach the desired area. This results in a loss of the calculated air distribution within the room, based on its dimensions, and unnecessary energy overconsumption.