Shaft misalignment is a defect that increases loads on couplings, which are then transmitted to shafts and other machine components, resulting in premature wear on bearings and seals, high temperatures, excessive vibrations, loosening of machine anchoring, and high electricity consumption.

Misalignment is the second most prevalent defect in industry, accounting for approximately 50% of machinery downtime.

The primary justification for prioritizing alignment is the potential for energy savings. The hidden costs associated with misalignment, particularly unnecessary energy consumption, represent the most compelling argument for improving alignment.

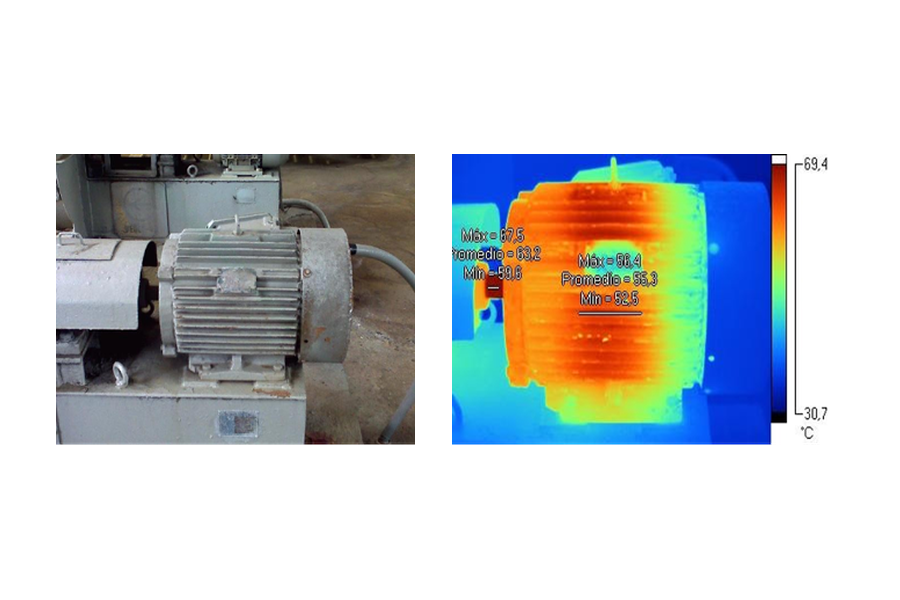

Next, we present a case study of a fan experiencing excessive current consumption, ranging from 2.7 to 3.9 amperes above the motor's rated current of 13 amperes.