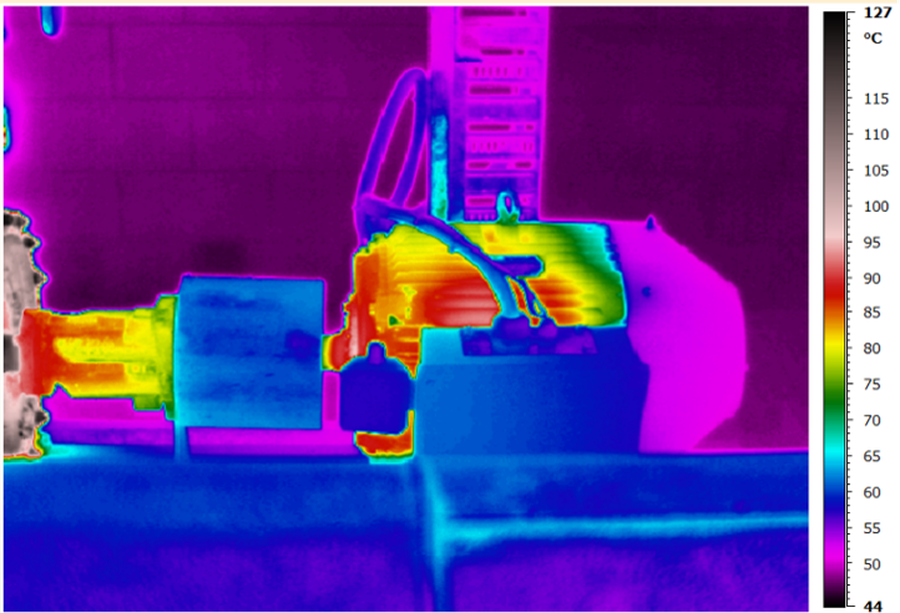

Coupling wear refers to the gradual deterioration of the contact surface between two joined mechanical components, such as shafts and bearings. This failure can be caused by constant friction, vibrations, or misalignment. As the coupling wears down, the efficiency of energy transmission decreases and there may be an increase in heat generation in that area. Infrared thermography is an effective tool to identify this type of failure, as it can detect areas with higher temperatures caused by the heat generated due to wear. This allows technicians to identify and address coupling wear before it leads to a complete breakdown, thus reducing downtime and repair costs.