Problems with pulleys can significantly impact the operation and lifespan of industrial machinery and systems. These failures can manifest in various ways, such as misalignment, excessive wear, overheating, and lack of lubrication. Early detection of these issues is essential to prevent further damage and ensure optimal performance.

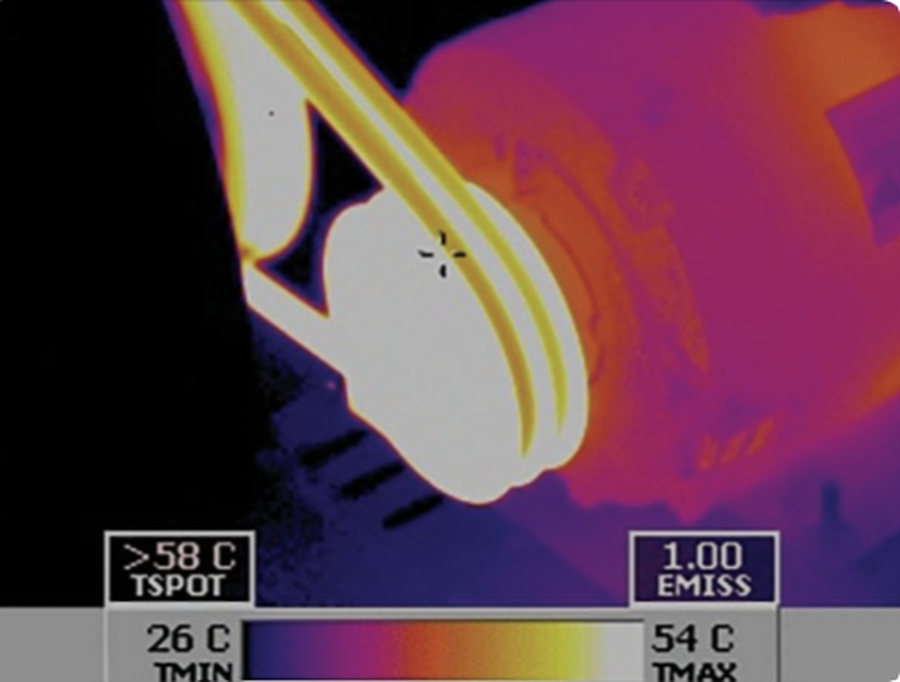

Infrared thermography proves to be a valuable tool in identifying pulley problems. This technique allows technicians to visualize temperature differences on the surface of pulleys, indicating irregular wear or areas of excessive friction. Additionally, thermography can detect hotspots that might be related to alignment or balancing issues.

A practical example of how infrared thermography can identify pulley problems is in inspecting belt drive systems. If a pulley is misaligned or if there's excessive friction due to a poorly adjusted belt, thermography can reveal abnormal temperature patterns on the pulley's surface. This enables technicians to take corrective measures before significant machine or system damage occurs.