Friction problems, also known as rub in the industry, can have a negative impact on the performance and lifespan of machinery and industrial systems. Excessive friction between components can generate heat and premature wear, potentially resulting in breakdowns and costly repairs.

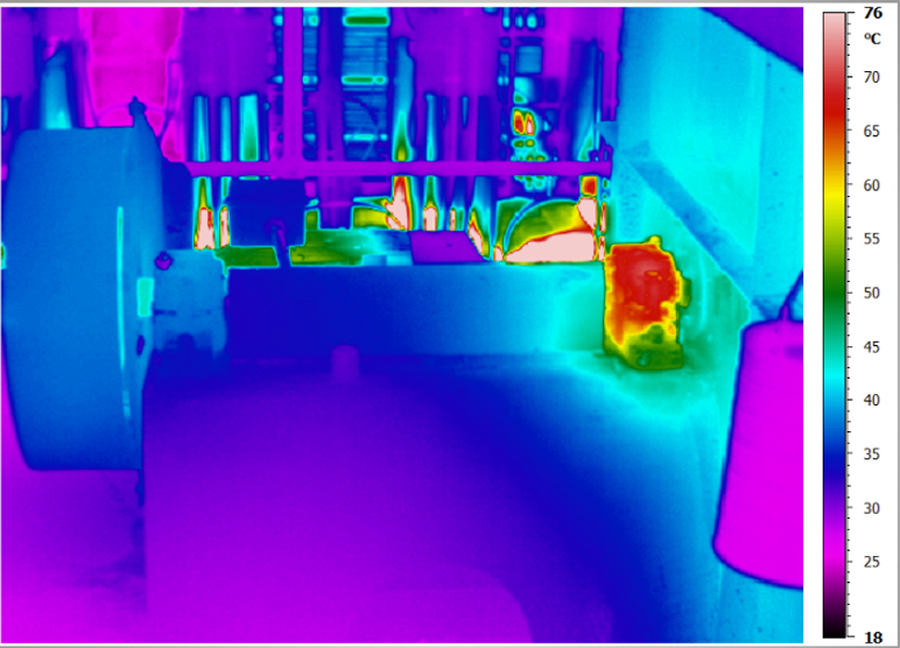

Infrared thermography emerges as an effective tool to identify friction problems. This technique allows professionals to detect temperature differences on the surface of components, revealing hot spots that could be experiencing excessive friction. By identifying these abnormal heat points, technicians can take preventive measures before they escalate into major issues.

A practical example of how infrared thermography can detect friction problems is in bearing inspection. If there is excessive friction or lack of lubrication in a bearing, thermography can show areas with elevated temperatures on its surface, indicating a potential friction issue. This enables technicians to take corrective actions before more severe equipment damage occurs.