Temperature indicating devices are used both to control process operations and to perform simple functional tests. Temperature is an indicator of the state of thermal insulation, high friction, poor lubrication, blockages in cooling systems, or poor ventilation, among others.

Bi-metallic thermometer

It operates based on two fundamental principles, the first is that the volume of metals changes with temperature. The change in the temperature / volume relationship is known as the "coefficient of expansion." The second principle is that different metals have different coefficient of expansion. Bi-metallic thermometers use these principles by having two thin sheets of metal with different coefficients of expansion and rolling them together. The extent of deflection that takes place is proportional to the square of the length and the change in temperature, and inversely proportional to the thickness. The thermometer provides a direct reading of the surface temperature of pipe or components. Temperature readings should be taken in close proximity to the measurement area.

Digital pyrometer

The pyrometer, which offers direct reading of temperature, is used when the temperature that needs to be measured exceeds the limits of mercury or other thermometers. The probe tip is placed on the part and the temperature that is read is on the surface. The pyrometer provides more accurate readings than surface gauges.

Temperature-sensitive crayons

Temperature-sensitive crayons are often used to obtain an approximate temperature. A mark is made with the crayon on the metal in the area that is being checked; For example, when using a 500 ° F crayon, the part temperature is at least 500 ° F when the mark melts. This measurement should usually be made within 1 ”(25.4 mm) of the base metal adjacent to the weld. The marks should not be made directly on the weld, due to its possible contamination. The use of each of the crayons is based on the maximum temperature at which it is melted, so it may be necessary to have a set of them, depending on your specific needs. The value of the temperature at which the crayon melts is usually indicated on a label and, depending on the temperature, the crayon has a distinctive color.

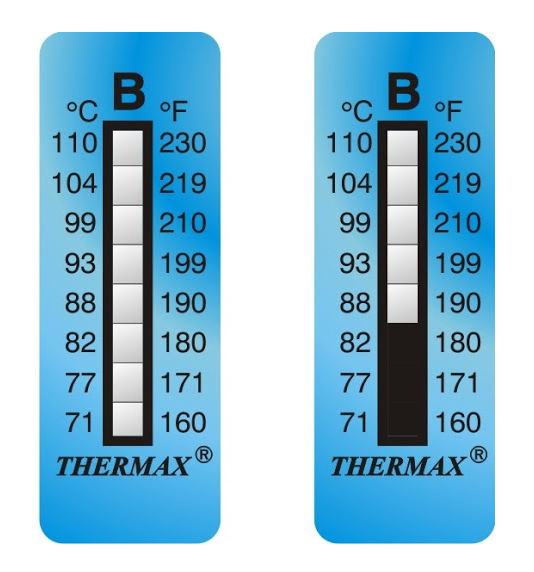

Temperature strips

Temperature measurement strips measure the surface temperature of the measurement object in certain temperature ranges or as a maximum value. To control the temperature, simply stick the self-adhesive films on the measuring object.