Linear measurements are those that involve a single dimension in a straight line in either the English or metric system.

There are drawings and specifications that provide dimensions and tolerances available. The type of linear measuring device to be used depends on the required tolerances and the accessibility of the dimension to be measured. Generally, dimensions with tolerances considered in fractions can be measured using steel rulers, while dimensions with tolerances considered in tenths or thousandths require greater measurement precision.

Vernier scale

The Vernier system is used in various measuring instruments such as Vernier calipers, Vernier micrometers, Vernier height, and depth calipers, Vernier gear teeth, and Vernier protractors; In addition, many industrial types of machinery use the Vernier system. Because the Vernier scale is basic to a variety of precision instruments, a full understanding of the Vernier is a requirement for their applications and handling.

A Vernier is a combination of two scales: the main scale and a Vernier scale. The main scale can be divided into inches, centimeters, or both. The principle for the use of both scales is the same. It is important to note that the Vernier is a non-fractional decimal instrument, so it provides the ability for precision. In the figure, we see a caliper or caliper.

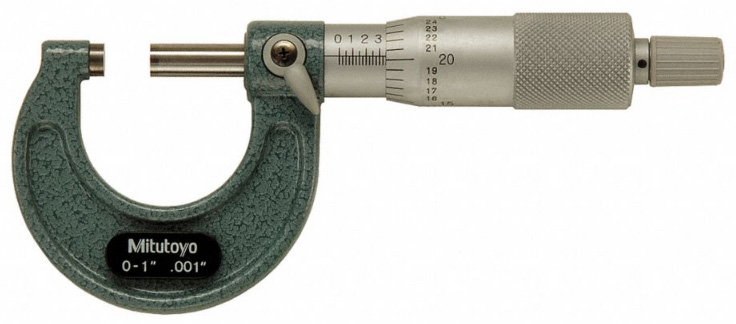

Micrometer

It is an extremely precise mechanical device. They are commonly used to measure thousandths of an inch, but there are also micrometers with which you can measure up to ten thousandths of an inch.

Micrometers are available in multiple sizes and shapes for special purposes, but the same principle is used to obtain readings. Outside, inside and depth micrometers are available. Some incorporate indoor and outdoor metering in the same unit. They are available with various measuring tips (which are normally hardened to prevent wear). These tips can be flat, rounded, pointed, or sharp. Micrometers can also be available or custom made. It takes a little training to use these accessories, but experience consistently produces more accurate results.

Dial indicator (dial)

It is also known as a dial, a stylus, a dial gauge, or a zipper watch. It is used when you want to scan the inspected surface. This measuring instrument consists of a graduated dial, usually calibrated in thousandths of an inch. There is a wide variety of measurement ranges and resolutions. It acts by thrust, the variation of the surface can be seen with the deflection of an indicator needle. Deflection occurs as the gauge or inspected part moves.

The dial indicator can be equipped with a number of mechanical arms or clamping devices so that it can be clamped to a fixed (rigid) object, thereby allowing measurements against a reference. A common use is clamping it to a lathe to check for horizontal and circumferential dimensional variations, and to check shaft alignment.