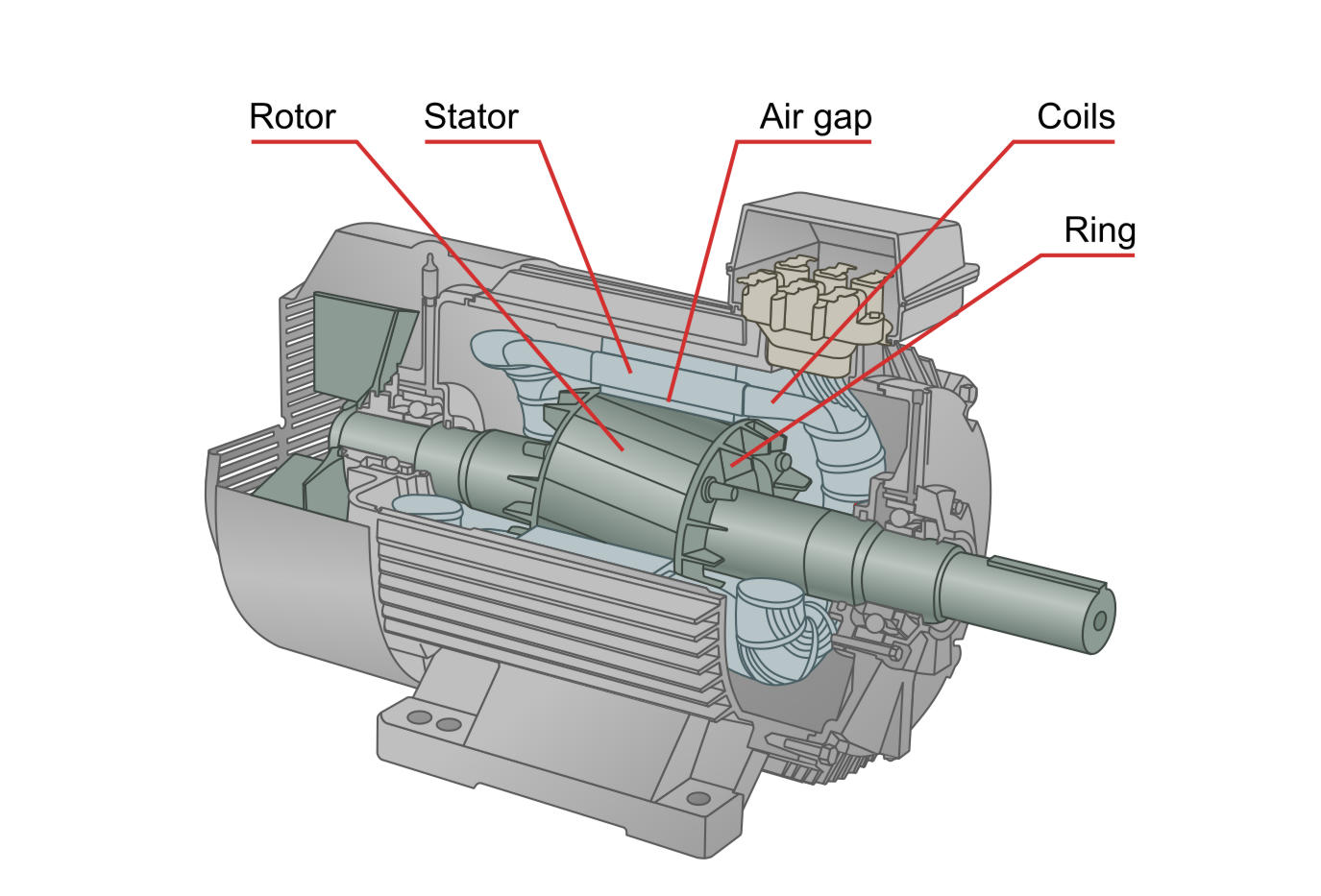

Asynchronous induction motors are probably the simplest and most robust of electric motors. The rotor is constituted by several conductive rods arranged parallel to the axis of the motor and by two conducting rings at both ends. The set is similar to a squirrel cage and is therefore also called a squirrel cage motor. The stator consists of a set of coils, so that when the three-phase alternating current passes through them, a rotating magnetic field is formed in the vicinity of the stator. This induces current in the rotor, which creates its own magnetic field. The interaction between both fields produces a torque in the rotor. There is no direct electrical connection between stator and rotor.

The line frequency of the alternating current determines the speed at which the magnetic field of the stator rotates. The rotor follows this field by turning more slowly, the difference in velocities is called slip. A normal slip is around 5%.

There are certain parameters and frequencies that must be identified:

- FL: Frequency of the electric power grid, usually 50 Hz (3,000 cpm) in the US 60 Hz (3,600 cpm).

- 2x FL: The alternating current is supplied as a sinusoid, in each cycle, each of the motor poles receives energy two times, once with a positive peak and another with a negative peak. This means that the most common vibration frequency that occurs is not the line frequency but twice the line frequency.

- P: Number of motor poles. The number of poles determines the motor turning frequency. The higher the number of poles, the slower the motor speed. Normally, the number of poles is an even number (2, 4, 6, etc.).

- NS: Synchronous speed. It is the speed of rotation of the magnetic field generated and the speed that the rotor tries to achieve but never reaches.

`sf "N"_"S" = (sf "2" xx sf "F"_sf "L") / sf "P" xx sf "60"`

- FS: Slip frequency.

`sf "F"_sf "S" = sf "N"_sf "S" - sf "RPM"`

- FP: Pole pass frequency.

`sf "F"_sf "P" = sf "P" xx sf "F"_sf "S"`

- WSPF: Winding Slots Pass Frequency.

`sf "WSPF" = sf "Number of stator winding slots" xx sf "RPM"`

- RBPF: Rotor Bar Pass Frequency.

`sf "RBPF" = sf "Number of rotor bars" xx sf "RPM"`

The most important thing to keep in mind when dealing with vibration related electrical problems is to look for amplitude increases and not just the presence of a peak or peak patterns. Once the problem has been detected by vibration, the next step should be to increase the monitoring frequency to detect a rising trend. In addition, some tests (surge testing, current analysis test, etc.) could be performed, but no action should be taken until the condition of the motor is known. Vibration is NOT the best way to monitor most electrical problems and this fact must be acknowledged.