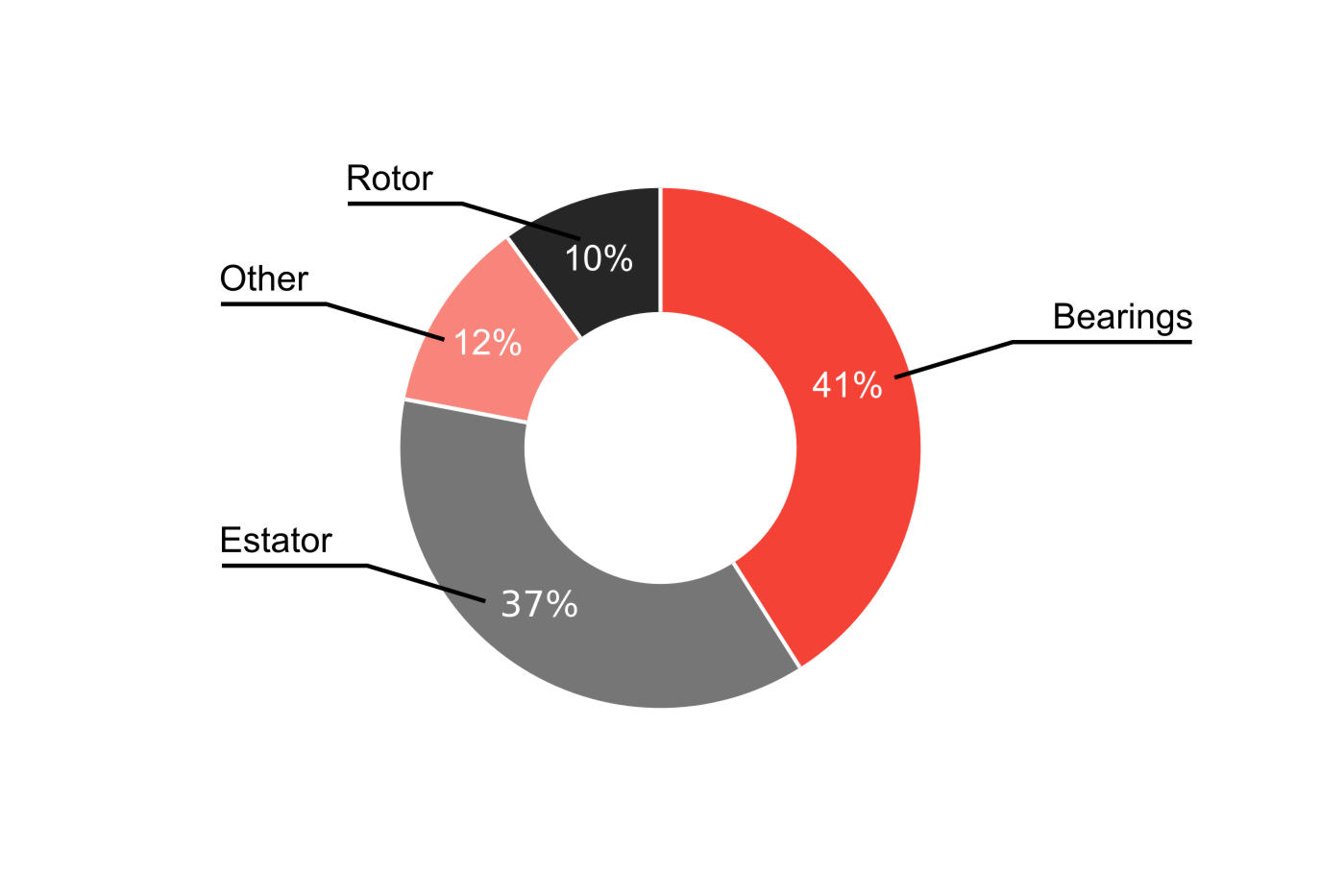

The main purpose of the application of specialized predictive techniques in electric motors is to detect problems in electrical rotating machines in such a way that production downtime due to unexpected outages are minimized. The other aspect involved is the reduction of costs by energy savings by having the appropriate tool to carry out acceptance tests after a costly repair and to be able to evaluate the efficiency of an electric motor or generator. When detecting electrical and mechanical problems in a rotating machine we can evaluate its condition and its operation efficiency since, in the majority of cases, the damage leads to a greater consumption of electrical energy and a decrease in reactive power, which is penalized by the electricity distribution companies. Studies conducted by the Electrical Power Research Institute (EPRI) in the United States in collaboration with General Electric show that the highest percentage of failure rates in electric motors (41%) is caused by electrical defects, even when a mechanical problem is the apparent cause.