Stator eccentricity, stator support weakness or winding shorts

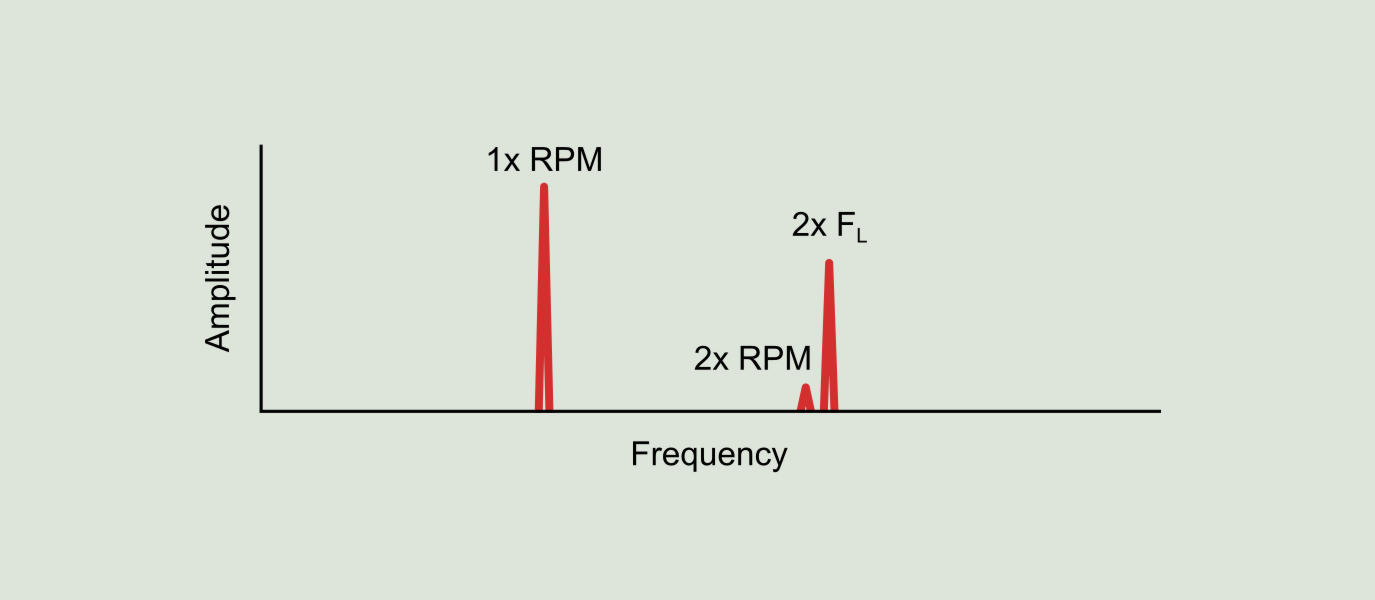

Stator problems generate high vibration at twice the line frequency (2x FL). The eccentricity of the stator produces an uneven stationary air gap between the rotor and the stator which causes a very directional vibration. The differences in the air gap should not exceed 5% for induction motors and 10% for synchronous motors. Loose foot and bent base plates (deformed) can produce an eccentric stator. Loose iron is due to weakness of the stator support.

Short-circuited stator windings can cause localized and uneven heating that can distort the stator itself. This produces a thermally induced vibration that can increase significantly over time, causing stator distortion and static air gap problems.

Eccentric rotor

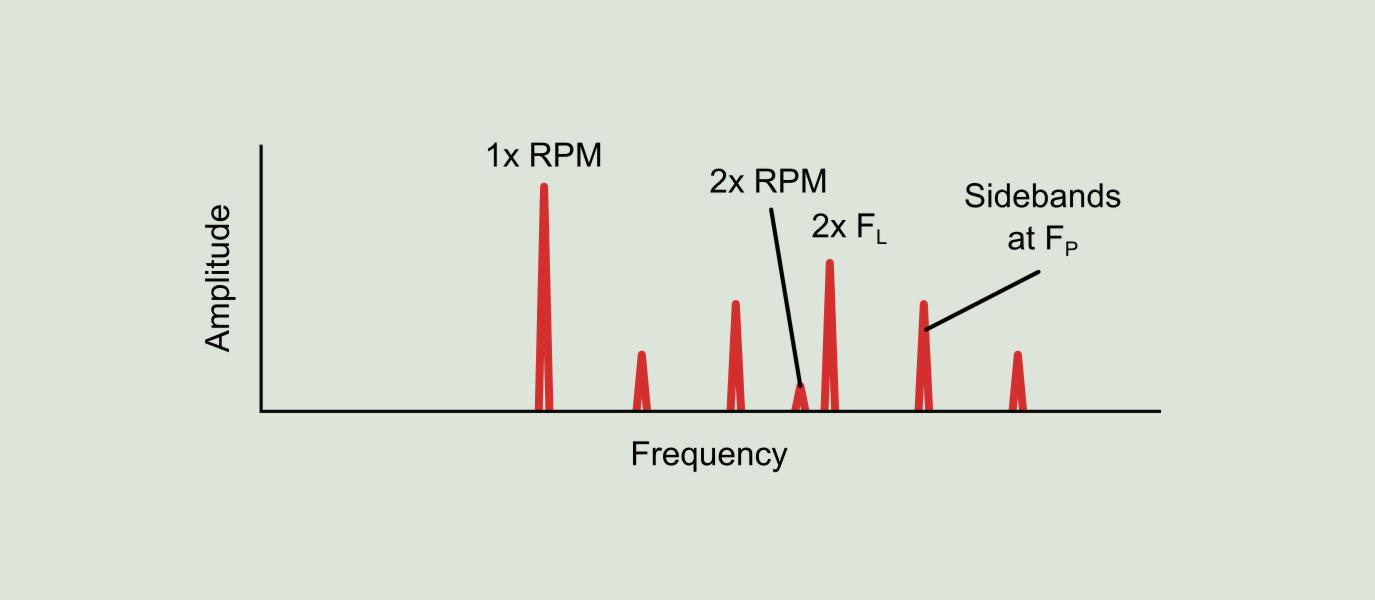

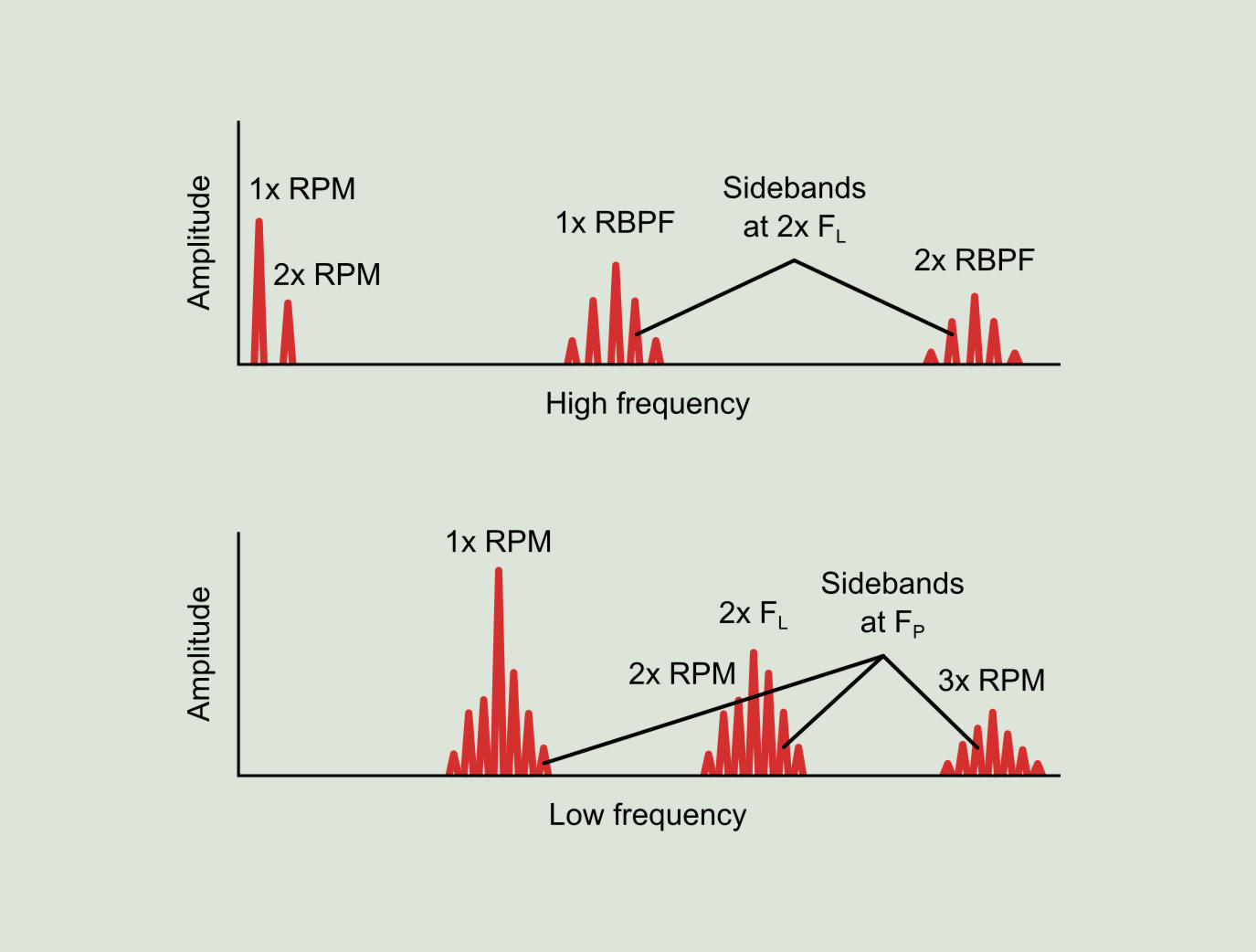

Eccentric rotors produce a rotating variable air gap between the rotor and the stator inducing a pulsating vibration, usually located between 2x FL and the nearest operating operating speed harmonic. Frequently it is necessary to "zoom in" the spectrum to separate 2x FL from the operating speed harmonic. Eccentric rotors produce 2x FL vibration surrounded by the side bands of the pole pass frequency (FP) as well as FP side bands around the operating speed. FP appears at low frequency since common FP values range from approximately 20 to 120 CPM (0.3 ~ 2.0 Hz).

Broken rotor bars or short-circuiting end rings, or shorted rotor laminations

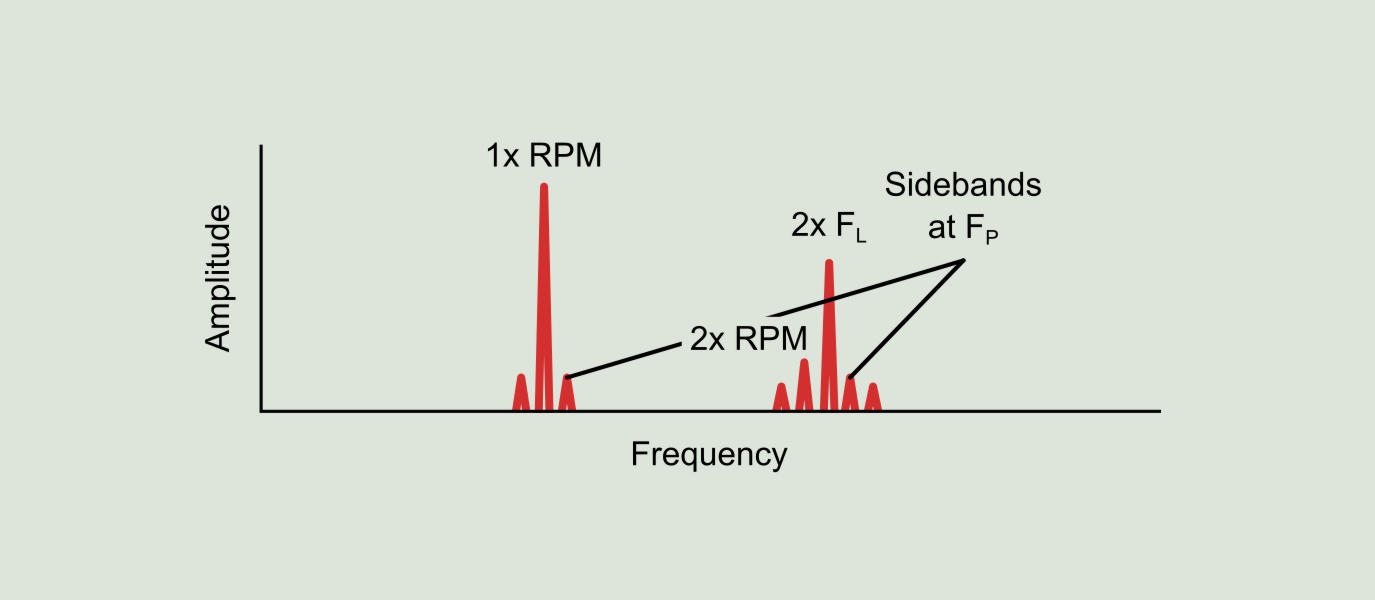

Broken or cracked rotor bars or short-circuiting end rings; bad joints between rotor bars and the short-circuiting end rings; or shorted rotor laminations will produce high vibration at the 1x RPM operating speed with pole pass frequency (FP) sidebands. In addition, these problems will frequently generate FP side bands around the second, third, fourth and fifth harmonic of the operating speed. Opened rotor bars are indicated by sidebands at twice the line frequency (2x FL) around the rotor bar pass frequency (RBPF) and/or its harmonics. Frequently, it will cause high levels at 2x RBPF with only a small amplitude at 1x RBPF. The electrically induced arc between the broken rotor bars and the end rings will often show high levels at 2x RBPF (with 2x FL sidebands); but little or no amplitude increase at 1x RBPF.

Phase problems (loose connector)

Phase problems due to loose or broken connectors can cause excessive vibration at twice the line frequency (2x FL), which will have side bands around it spaced at 1/3 of the line frequency (1/3 FL). Levels in 2x FL may grow significantly if left uncorrected. However, there may be cases in which the only symptom is an amplitude increase in 2x FL. This is especially a problem if the faulty connector only makes sporadic contact. Connectors with bad contact or broken should be repaired to avoid catastrophic failure.