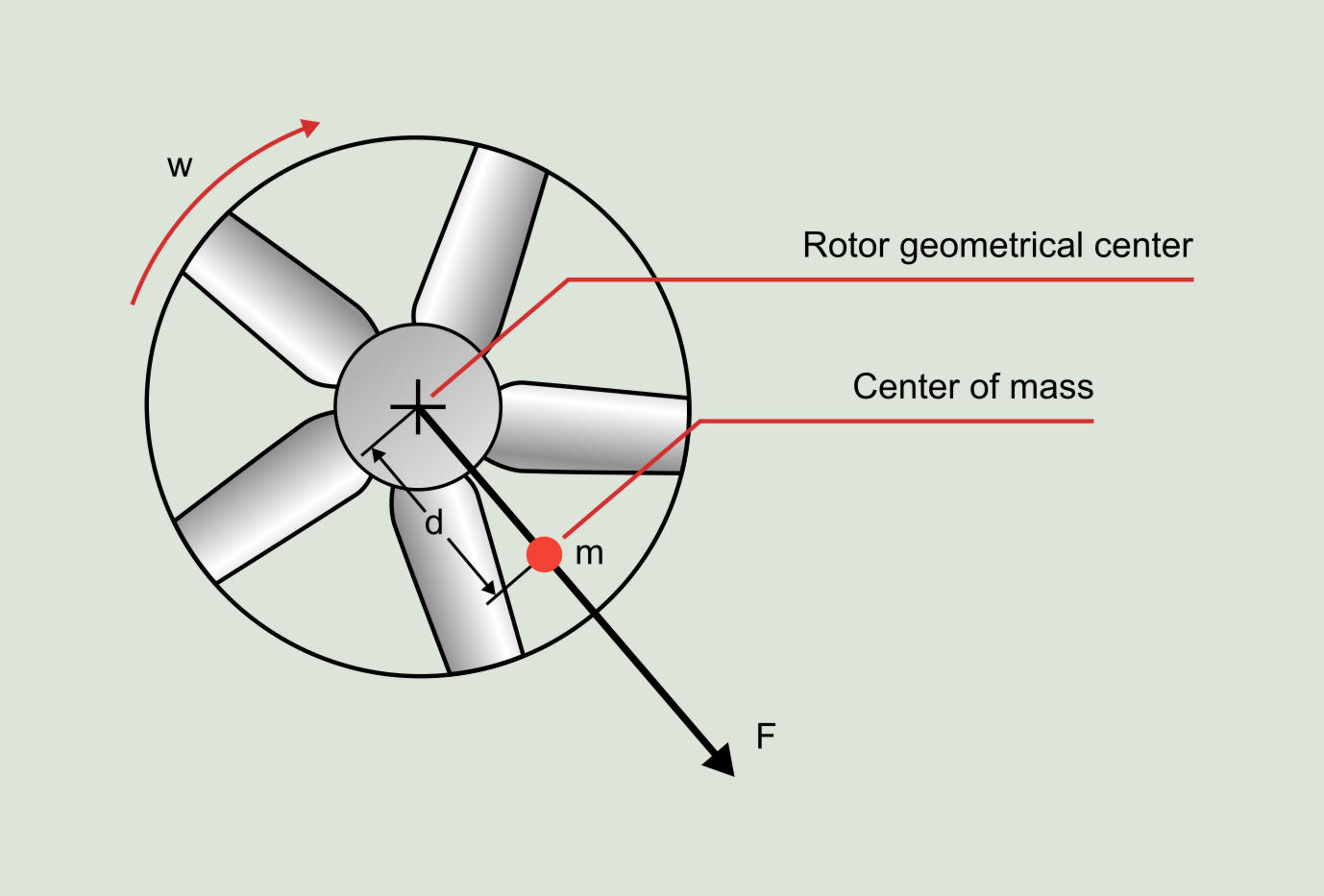

A rotating machine is imbalanced when the rotor center of gravity or center of mass does not coincide with its center of rotation or geometric center. This results in a centrifugal force which (as shown in Figure 5.2) originates at the center of rotation is directed radially and rotates synchronously with the shaft causing excessive vibration.

Among the main characteristics of imbalance we can highlight the following:

- The vibration amplitude is directly proportional to the amount of imbalance.

- A variation in imbalance will cause a variation in vibration phase angle.

- The vector sum of all weights at the same plane is equivalent to a single resulting imbalance.

- The amount of imbalance can be quantified by the weight and distance from the rotor center to the weight (grams x cm). An increase in the imbalance weight or the radius will cause an increase directly proportional to the amount of imbalance where,

m = imbalance mass

d = imbalance radius

w = angular velocity

`sf "F" = sf "m" xx sf "d" xx sf "w" ^ sf "2"`

The source of imbalance can be of very different origin or nature such as the following:

- Uneven accumulation of dust in fan blades.

- Erosion and uneven corrosion of pump impellers.

- Lack of homogeneity in cast parts, such as bubbles, blow holes and porous parts.

- Rotor eccentricity.

- Unequal distribution in electric motor rotor bars or windings.

- Bent roller, especially in paper industry machines.

- Missing balance weights.

- Bent shaft.

- Eccentricity.