What to Do Before a Laser Shaft Alignment

We must consider some actions before performing laser shaft alignment to ensure that everything goes as planned and for the shaft to be aligned without any problem. So let’s take a look to learn what to do before a laser shaft alignment.

Workplace hazards during laser shaft alignment

As well as many industrial tasks, shaft alignment services expose the personnel to certain workplace hazards. These hazards must be addressed before starting the shaft alignment services to eliminate or at least minimize such hazards.

Some of the hazards involved in the laser shaft alignment services are:

- Caught-in hazards.

- Burning hazards due to contact with hot parts.

- Electrocution hazards.

- Falling hazards.

- Falling objects hazards.

There are other hazards associated with the laser shaft alignment services. If you wish to learn more about the workplace hazards while performing this and other asset inspection activities, you can do it by visiting our workplace hazards learning section.

On the other hand, the actions to take before the alignment of the shaft with laser alignment equipment to eliminate or minimize such hazards are:

- Knowing the personal protective equipment that must be used during the alignment of the shaft.

- Speaking to the health and safety managers to ensure that the machine is consigned and there is no risk to have the machine started.

- As part of the consignation of the machine, the power supply and all the electric switching must be disconnected if possible. In some cases, locking devices are used to prevent the machine from starting operation.

- It is also recommended to identify the machine as consigned by using the corresponding tags.

On-site activities coordination

When the laser shaft alignment is performed on-site, it is necessary to coordinate the activities with the company receiving the shaft alignment services.

This coordination includes:

- Defining the documentation needed to access the areas where the shaft alignment will take place. This includes working at heights permits.

- Informing about the workplace hazards and the measures that must be taken to eliminate or minimize them. This must include the procedures and escape routes in case of emergency.

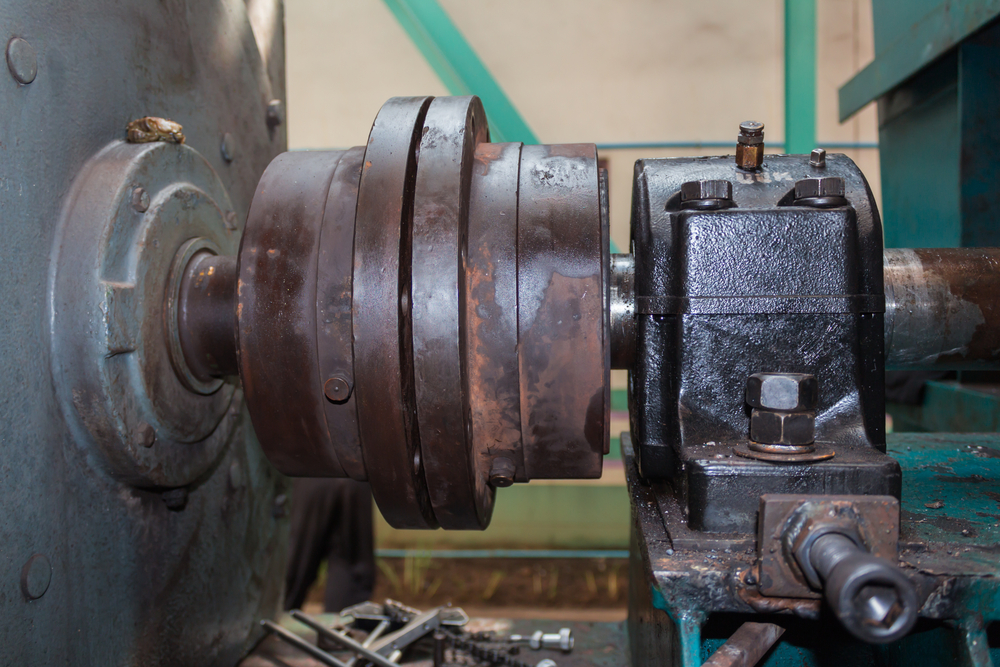

- Requesting photographs of the machines that will be aligned if possible. This allows selecting the correct type of mounting brackets for the laser alignment equipment depending on the machine’s coupling.

- Requesting the information about the machine which is needed to perform the shaft alignment the right way.

Information about the machine needed for the laser shaft alignment

As part of the information that must be coordinated with the company, one of the most important pieces is the information about the machine, which enables a correct shaft alignment. This information includes:

- Type of coupling used in the machine.

- Type of shaft used in the machine, for example, universal joint.

- Location of the machine and access ways.

Soft foot verification

The soft foot in rotating machinery is a significant problem that must be detected and corrected before it creates bigger problems and severe damage on the machines.

It is recommended to verify the possibility of the soft foot before performing the shaft alignment. This problem might be a direct cause of misalignment, meaning that it can also affect the alignment performed. Follow these steps using a shaft alignment system:

- When using the alignment device, the laser and the sensor are placed on the shaft, and the function to measure the vertical displacement of the equipment is selected. This will measure the displacement resulting from loosening a bolt in the base.

- Repeat the process for the 4 or 6 feet of the machine.

The alignment equipment calculates the distance the machine is moving and determines whether there is a soft foot. If the result is in the range of 0.002 inches (0.0508 millimeters) to 0.003 inches (0.0762 millimeters), then there is a soft foot.

Read more about the soft foot in rotating machinery.

Pre-Alignment

Once the previous steps are completed, and only the laser shaft alignment is missing, proceed as follow:

- Remove the shaft protection to get access to it. This is usually requested by the asset owner and performed by the personnel of the site.

- Since the shafts tend to be dirty, they must be cleaned to guarantee the accuracy of the shaft alignment and to protect the integrity of the laser alignment equipment.

- It is recommended to place a rag under the protection to prevent the contamination of the laser alignment equipment with grease and other substances.

- If a soft foot is detected, it must be corrected before aligning.

While correcting the soft foot issue or in case of severe misalignment, pre-alignment is recommended. This can be done quickly by using a dial indicator, and it is a process that speeds up the final shaft alignment.

Also, it ensures that the laser is perfectly pointing into the center of the sensor. In severe misalignment, the problem can be corrected by taking partial measures until the laser gets out of the sensor’s reading area.

To ease the process in these cases, it is also possible to use the laser alignment equipment function, which is called “extend range”. This function allows making the measuring range wider for severe misalignment. Using this function, the equipment is given the input of the point where the laser gets out of the sensor range, then the laser is moved back into the range, and a new measure is taken until it gets out of the range again. This process is repeated until sufficient measures are taken with the angle required for the equipment to generate the alignment circumference.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more