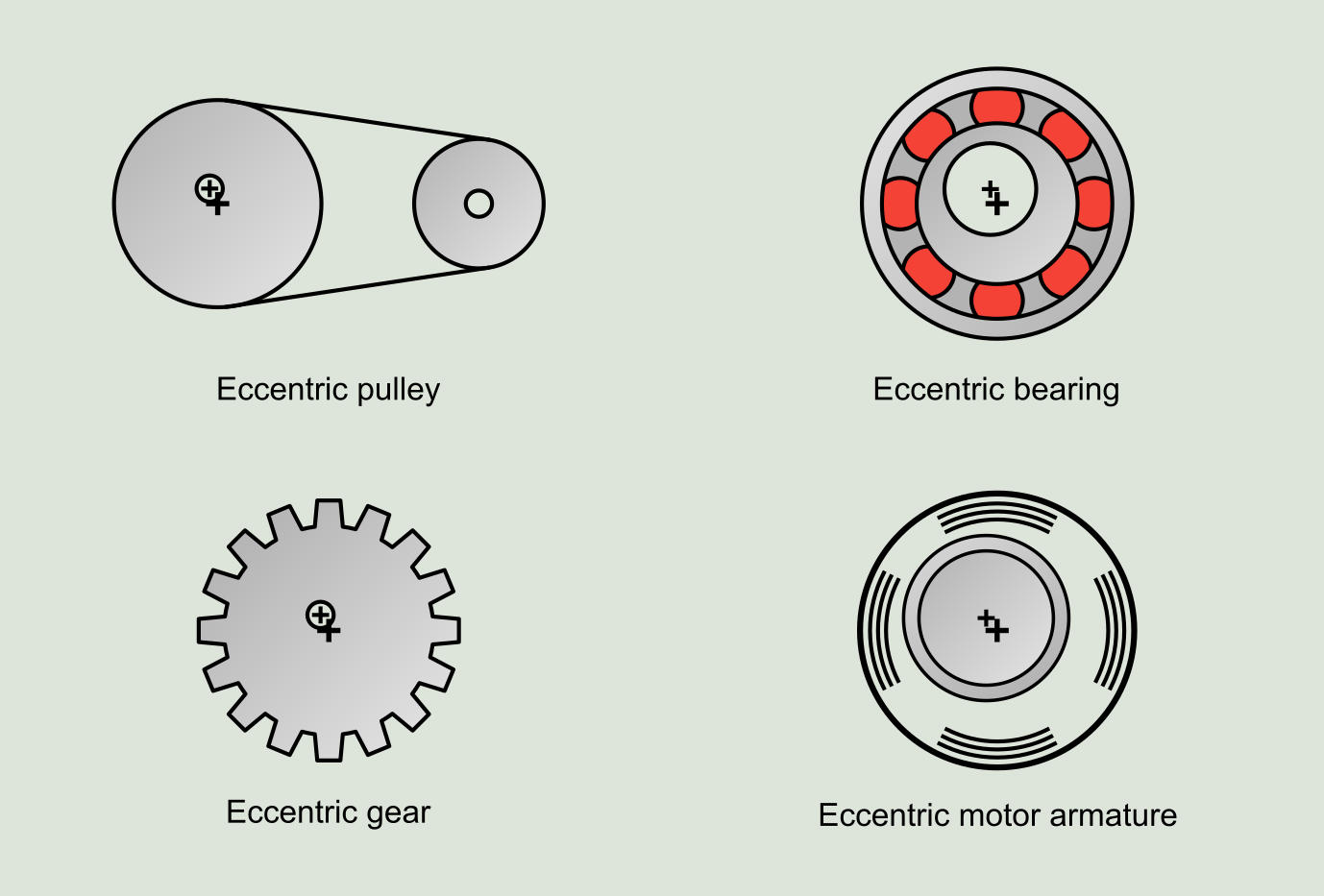

Eccentricity is defined as the offset between the axis of rotation and the axis of symmetry. Eccentricity can take place in different types of mechanical elements, such as pulleys, gears and in any relative positioning between two concentric pieces, as for example the rotor and the stator of an electric motor.

Due to the general improvement in manufacturing processes eccentricity is nowadays not a common phenomenon, having its root-cause mainly in an uneven surface wear. This is the case of wear on pulley grooves. In electric motors, eccentricity caused by the incorrect relative positioning between the rotor and the stator is related to a progressive decrease of the air gap by the manufacturers with the objective of increasing the motor efficiency.

Eccentricity manifests differently in a pure mechanical element, such as a pulley, than in the case of an electric motor where there is also present a magnetic field. Eccentricity problems in electric motors are discussed in detail in Chapter 10.

Pulley eccentricity

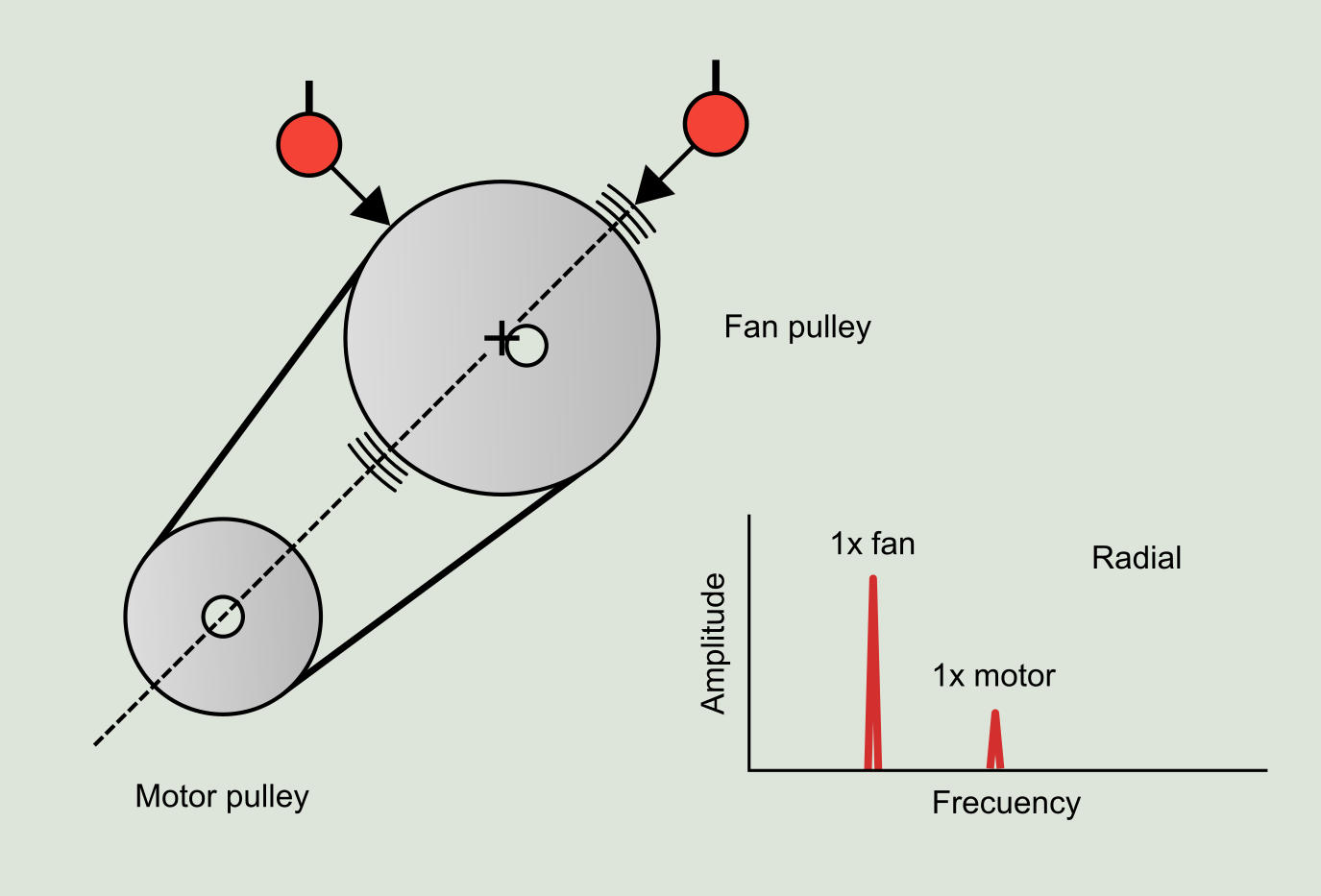

Eccentricity manifests in the same way as unbalance, with a strong vibration component at the turning frequency of the pulley in the radial direction. If it is diagnosed as an unbalance, the problem may be corrected, but the eccentricity is usually dependent on the load, so when the load conditions change with respect to those during the balancing, then vibration levels can increase.

The phase is a parameter that is available to differentiate eccentricity from unbalance. As discussed in the previous chapter, with unbalance there is a 90° diference between the two radial readings. In the case of eccentricity, a periodic variation in the belts tension is produced. The reaction force on the pulleys causes a movement of the pulleys in the direction of the this force so if radial phase readings are taken on the pulley, these readings will be in phase as shown in Figure 6.2.

In a spectral reading taken in line with the two pulleys, the frequency of the worn pulley is usually seen from the other pulley.

If the belts are removed and the rotating speed harmonic is significantly reduced, it is quite likely that the problem is wear on the pulley's outside diameter.