Air Gap Monitoring in Motors and Generators

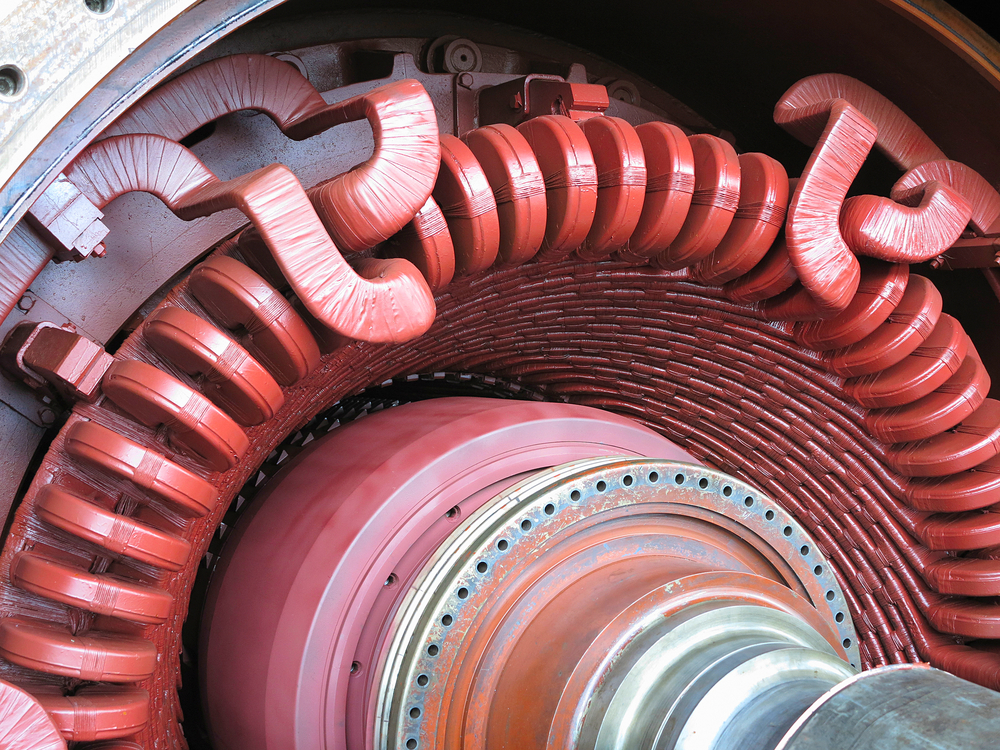

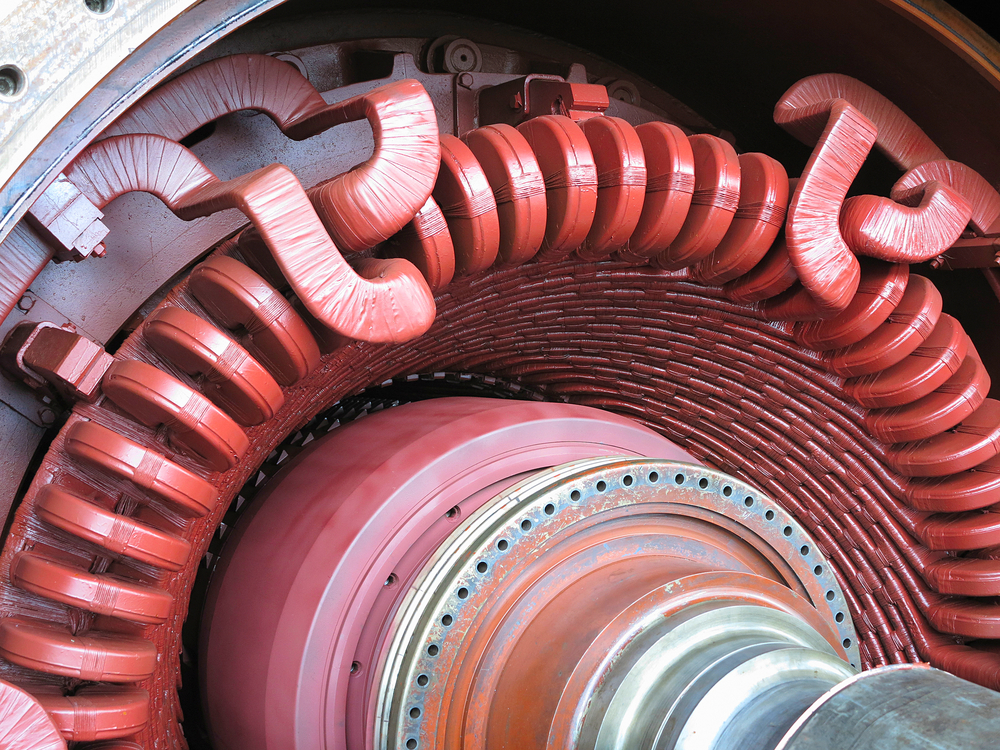

Before talking about air gap monitoring in motors and generators, it is essential to clarify an electric motor or generator's air gap and what it does.

What is the air gap?

A simple way to define the air gap is to say that it is the air in the space between the stator and the electrical machine's rotor.

Monitorización del entrehierro en motores y generadores

Antes de hablar sobre la monitorización del entrehierro en motores y generadores, es importante tener claro qué es y qué función tiene el entrehierro de un motor o de un generador eléctrico.

¿Qué es el entrehierro?

Una manera simple de definir el entrehierro es decir que es el aire contenido en el espacio entre el estator y el rotor de la máquina eléctrica.

How to Calculate Condition-Based Maintenance Savings

Calculating the savings by predictive maintenance allows us to justify all the investments in technology, services and personnel. It also serves as the foundation to calculate the ROI (Return or Investment) of condition-based maintenance.

In this article, we will explain in a simple way how to calculate the direct savings generated by predictive maintenance to be able to justify investments, gain visibility in the company (or client) and quantify the value that is contributed to the company.

Cómo calcular los ahorros generados por tu mantenimiento

Calcular los ahorros por mantenimiento predictivo nos permite justificar todas tus inversiones en tecnología, servicios y personal. Igualmente, nos sirve de base para calcular el ROI (Return On Investment) del mantenimiento basado en la condición.

En este artículo, vamos a explicar de forma sencilla cómo calcular los ahorros directos generados por mantenimiento predictivo para poder justificar inversiones, ganar visibilidad en la empresa y cuantificar el valor que se aporta a la empresa.

Somos miembros de SAP PartnerEdge open ecosystem

Power-MI es ahora miembro de SAP PartnerEdge open ecosystem a partir de septiembre de 2020. Como miembro del SAP PartnerEdge open ecosystem, Build, nuestros usuarios pueden transferir las órdenes de trabajo creadas en Power-MI a SAP Plant Maintenance (SAP PM). La aplicación nos permite crear órdenes de trabajo a partir de Application Programming Interfaces (APIs).

We Are Now a Member of the SAP PartnerEdge

Power-MI is now a member of SAP PartnerEdge open ecosystem as of September 2020. As a member of the SAP PartnerEdge open ecosystem, Build, our users can transfer work orders created in Power-MI to SAP Plant Maintenance (SAP PM). The application allows us to create work orders from Application Programming Interfaces (APIs).

Nueva versión de la guía del usuario Power-MI

El software de mantenimiento predictivo Power-MI lanza nueva versión de la guía del usuario. La nueva guía del usuario es ahora online y contiene los temas principales de ayuda para configuración y uso del software para gestionar el mantenimiento basado en la condición (CBM).

Otra novedad es que la guía del usuario de Power-MI incluye videos de ayuda para acelerar el aprendizaje de los usuarios. Los videos están disponibles en nuestro canal de Youtube.

The New Version of Power-MI User Guide

Power-MI predictive maintenance software launches a new version of the user guide. The latest user guide is now online and contains the main help topics for setting up and using the software to manage condition-based maintenance (CBM).

New to the Power-MI user guide includes help videos to speed up user learning. The videos are available on our Youtube channel.

Vibration Analysis in Gearboxes

What is a Gearbox?

A gearbox is a kind of container for integrated and synchronized gear trains. In the operational sense, a gearbox is a machine component with the ability to change speed and torque between a driving device and a driven device, for example, between a motor and a coupled load. Gearboxes are also used to change the direction of rotation and the direction of the drive shaft. The mechanical components that enable these functions are called gears, and within gearbox terminology, there are different types.