Taxonomy for Assets Hierarchy

To understand how the hierarchy of assets is defined, we must first understand what taxonomy is. According to ISO 14224, it is a systematic classification of elements into generic groups based on factors possibly common to all aspects (location, use, the subdivision of equipment, etc.). In other words, taxonomy is in charge of creating the identification of assets according to their position in the hierarchy based on the factors mentioned above.

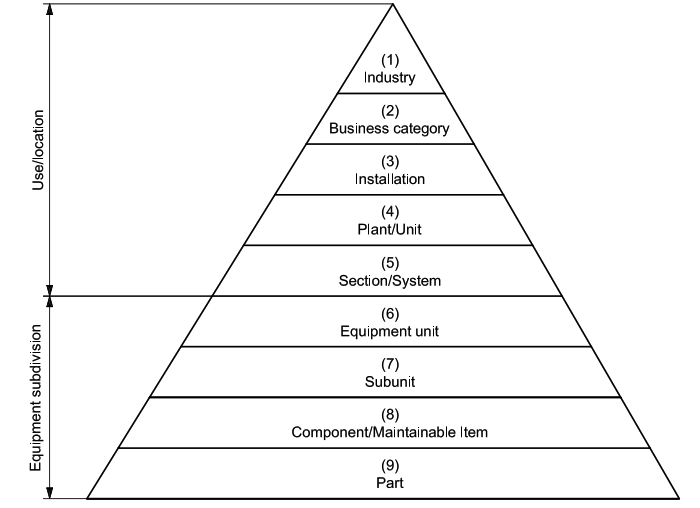

The ISO 14224 standard offers a hierarchical pyramid of taxonomic classification with nine levels, with level 1 being the highest, representing the type of industry, and level 9 being the lowest, representing a part or piece.

Besides, the pyramid also indicates that levels 1 through 5 refer to the use and location of the asset. Levels 6 through 9 represent the subdivision of the asset.

The taxonomy in condition monitoring

The taxonomy of assets in the inspection or condition monitoring analysis is vital so that the information collected in the reports is easier to understand and thus facilitate decision-making. In other words, the taxonomy helps that this information is related to the corresponding taxonomic hierarchy level and therefore has a clear and comparable meaning to determine the condition of the inspected asset.

The ISO 14224 standard focuses on level 6 of the taxonomic hierarchy, that is, at the level of the industrial asset to collect reliability and maintenance data. However, the same industrial asset, such as a hydraulic pump or any other asset, can be used in different industries and, even more, in various plant configurations. That is why, to carry out the inspection or monitoring analysis of similar equipment conditions, it is also essential to know the context in which they operate.

Therefore, the most important levels when applying the taxonomy in condition monitoring include:

- Industrial plant

- Section

- Industrial Asset

Let's analyze how these levels are defined and at what they represent within the hierarchy of ISO 14224.

Industrial plant

An industrial plant is a facility or a place of production that is made up of different parts, intertwined with each other, and called sections. According to ISO 14224, the plant is level 4 of the asset hierarchy taxonomy. Some examples of this level are methanol plants and compression stations.

Section

A section is a system within a plant that executes a function, but whose beginning and end are interlaced to other sections of the same plant. Likewise, a section can be a location within the same plant and whose function is auxiliary to the plant. According to ISO 14224, the section is level 5 of the taxonomy of the asset hierarchy. Some examples of sections are compression, natural gas, charging systems, among others.

Industrial Asset

An industrial asset is an equipment that can be classified according to the type of function it performs. In predictive maintenance, an industrial asset is what an inspection report or condition monitoring analysis refers to. According to ISO 14224, the asset is level 6 of the taxonomy of the asset hierarchy. Some common examples of this level are boilers, tanks, valves, sensors, compressors, heat exchangers, hydraulic pumps, and many others.

Important considerations

It should be noted that the three levels mentioned above are not the only ones to include in inspection reports, condition monitoring analysis, and other types of reliability analysis. Some analyzes, such as root cause analyzes, may require information about the failure mechanism at the level of components or elements that correspond to lower levels of the hierarchy. This information must also be appropriately categorized using the taxonomy described here.

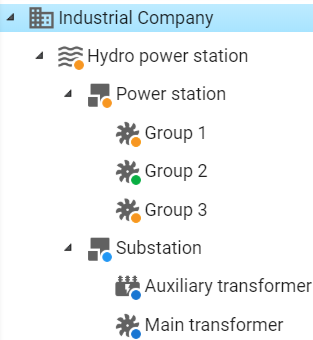

Power-MI allows users to create assets hierarchy according to ISO 14224, where you can allocate plants, sections, sub-sections, and assets. Condition monitoring users encounter an intuitive cloud-based Industry 4.0 workplace that allows managing predictive maintenance professionally, and it is effortless to use. The development of all software functionalities is based on user feedback. This enables us to continuously improve our solution while keeping it intuitive and straightforward for optimal user experience.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more