Is Shaft Alignment Predictive Maintenance?

Shaft alignment by concept is a corrective maintenance task. The shaft is moved to achieve more efficient power transmission. Traditionally installing dial indicators, adjusting and measuring only to take readings and then not correct, is a useless task.

The incorporation in the industry of laser shaft aligners allows an alignment measurement extremely easy, fast and delegable to any person of the maintenance team. There is a noticeable change in the industries that incorporated this technology, and they begin to make measurements of checking the alignment. Users measure to verify the alignment status of the shafts and not just to correct.

In critical machinery, periodic shaft alignment measurements are only programmed to check whether or not the machine's alignment needs to be corrected. The readings measured is compared with limits or tolerances. Thus, alignment equipment is used not only to align but also to monitor the condition of the machine. It is from this perspective that the measurement of the alignment of the machine is a task of predictive maintenance or condition-based maintenance if it is done to monitor the alignment condition.

Semantically it is incorrect to say that aligning is predictive maintenance, the action of aligning implies corrective action. However, the measurement of alignment is a predictive maintenance task under the concepts of verification. In fairs, congresses and discussion forums we have opened this debate, and there are always different opinions, even the types of maintenance are understood in different ways.

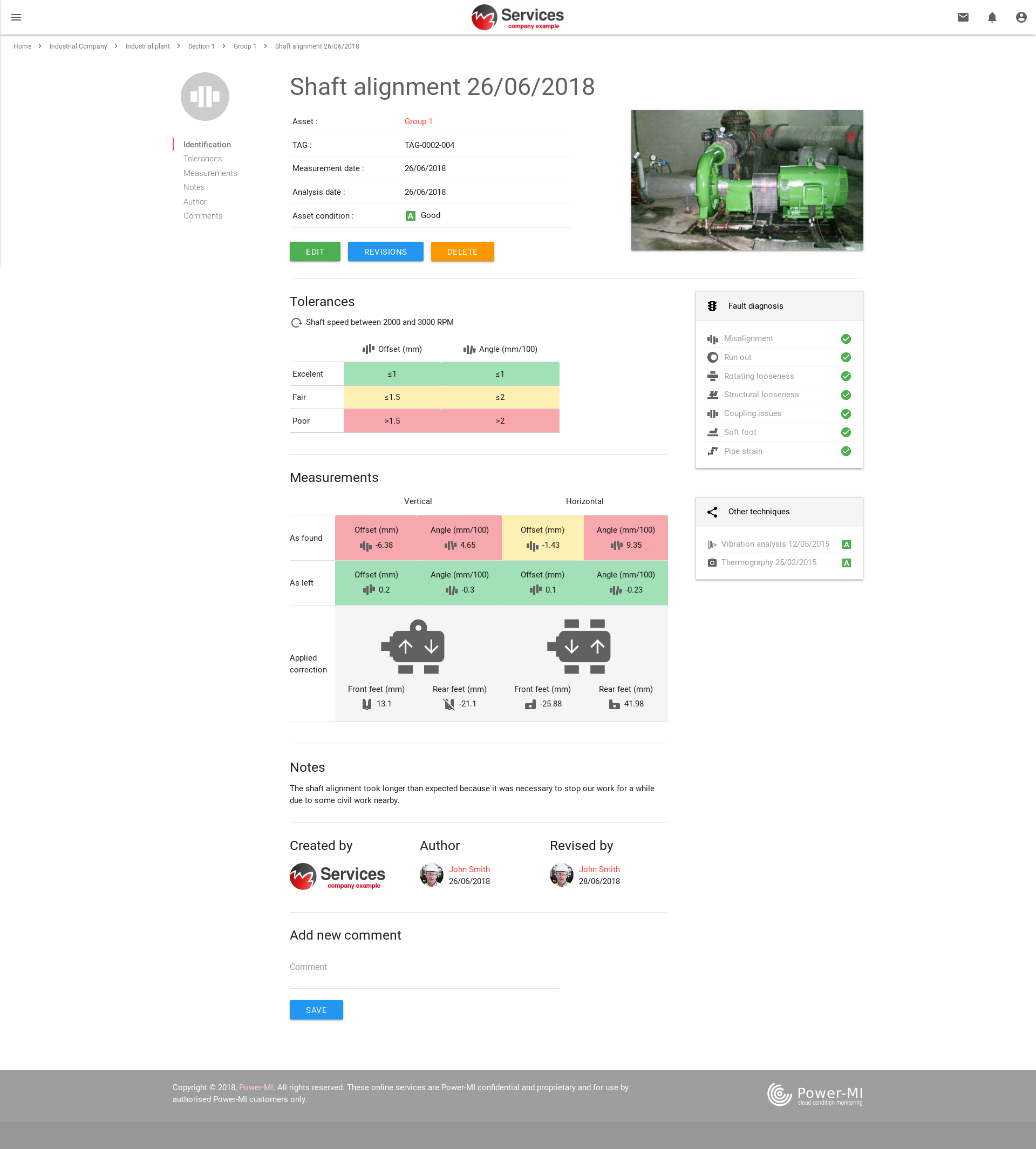

We consider the measurement of shaft alignment for condition monitoring as predictive maintenance, that is why we must report it and save its history. Like all predictive technology, it is necessary to combine it with other techniques to make valid decisions. That's why our Power-MI software platform includes "Shaft alignment" as a predictive maintenance task and allows users to group alignment reports with vibration, oil analysis, thermography and other predictive technologies into a single software.

The alignment has a custom report format and its failures catalog that can be detected during an alignment measurement routine. This will be the subject of another article.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more