Roll Alignment in the Steel Industry

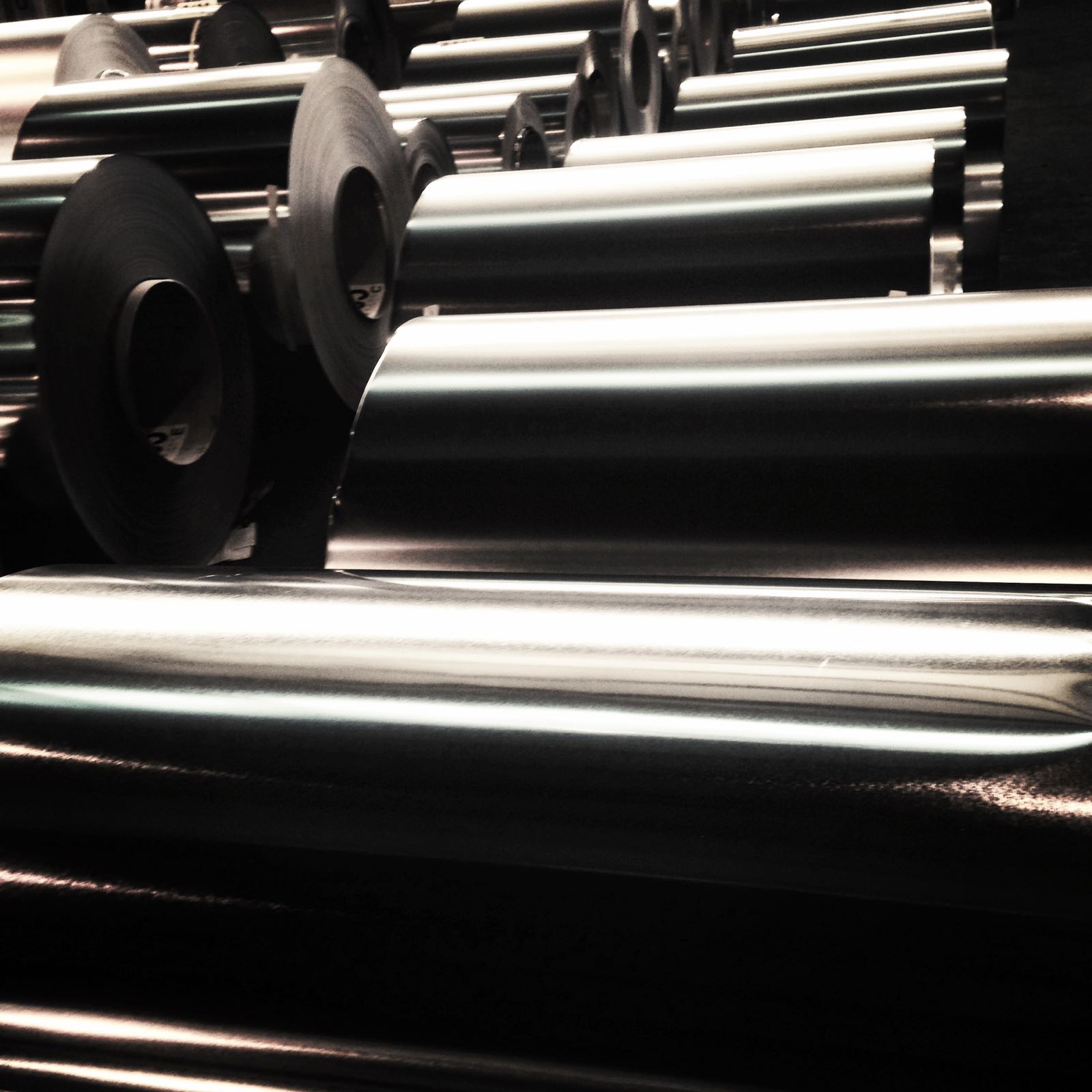

For those of you who are fairly familiar with the steel industry, you may know that steel is processed in coils. Well, steel processing is mostly done by rollers, either hot or cold.

Steel is the alloy of Iron and Carbon. So far, this is what I knew before I started doing roll alignment work in the steel industry.

And this is what I've learned over time. To manufacture steel, a mixture of iron ore (with impurities) and a fuel called coke can be poured into a blast furnace. If it is made from scrap metal, it is previously melted in an electric blast furnace.

The lamination of the steel is done by transforming the finished product reducing its thickness and, logically, elongating it. Steel sheet and obtained from slabs, which changes its granular structure, which determines its hardness, strength, and ductility. That is why flat steel can have several processes among which we have:

- Hot rolled

- Pickling

- Lamination

- Tempered

- Galvanized

In these processes, steel is processed form an extremely long sheet, which is why it is stored and transported in coils.

Likewise, these processes involve the processing of the continuous sheet of steel in rollers. And it is there where we come to the point.

Rollers in the steel process

The rollers are in charge of supporting the weight of the steel, guiding the steel, and reducing the thickness. The rollers are the primary and most expensive consumables of rolling mills, and their performance depends on many factors such as its material, loads, and operating conditions, between the s that is its alignment.

What is roll alignment?

When I mention roller alignment, I mean the parallelism that has to be between them. However, some people call roll alignment t the collinearity between rollers and motor either by coupling or cardan shafts. Here, I am going to refer to the parallelism of the rollers.

How is roll alignment measured?

The alignment of rollers has traditionally been a highly specialized task due to the precision it entails and, usually, in a short time with which the machine is counted once it is stopped.

I still find companies that hire the services of technicians who use theodolites to measure the parallelism of the rolls. However, I find theodolites fewer due to visual connection mus exist to measure between objects.

Theodolite is very useful when you want to set the rollers to "zero." That is, referred to gravity. Its most significant drawback, in addition to what was mentioned previously, is that it takes a long time to align a roller. I don't think you could check more than ten rolls in one day. Furthermore, its precision is not too demanding.

Other alignment methods are mechanical and laser systems, which is the visual comparison of projected references.

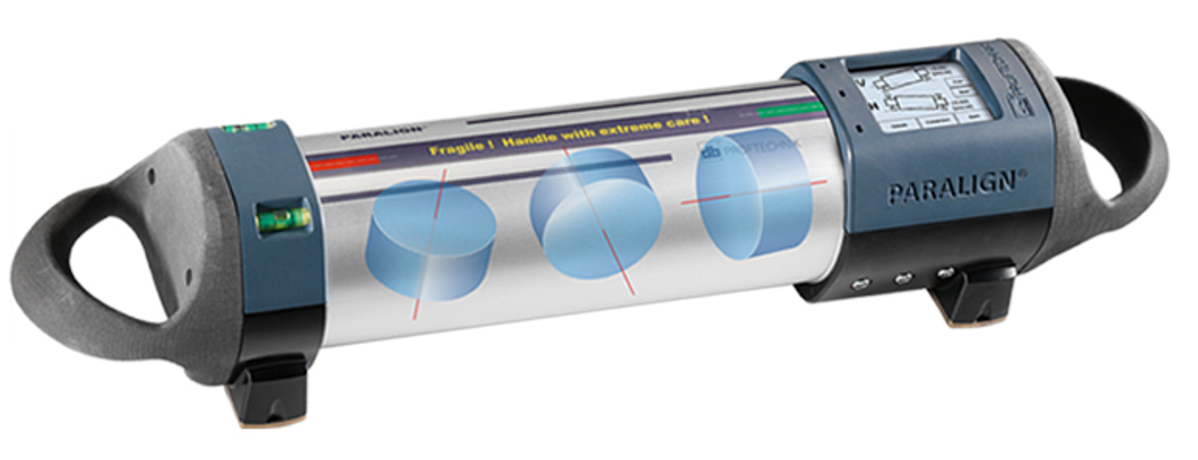

The method of measuring roller parallelism, of which I am an expert, is the PARALIGN® method of the PRÜFTECHNIK company, which is a system that uses aerospace technology in installations with belt guidance (steel, pulp, and paper, plastic, printing, tires ...).

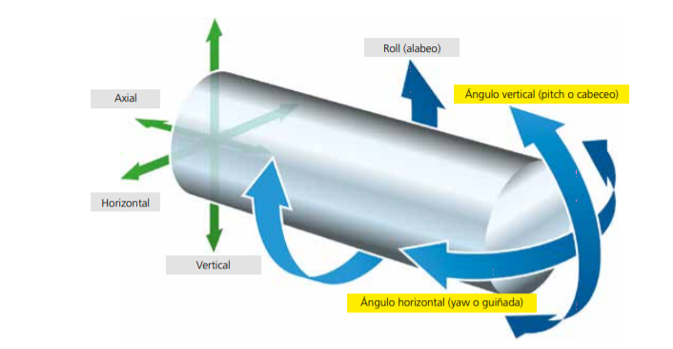

The device houses three ring laser gyros that describe the three possible positions, roll, pitch, and yaw.

To make the measurements, simply slide the PARALIGN® on the surface of the roller, or instead attach the device on the roller and rotate the roller so that, by gyroscopes, you get the axis of rotation of the roller and transferred by Bluetooth to a PC.

The measurement result is displayed on the PC at the moment. In just 1 minute, a roller can be measured with unmatched precision.

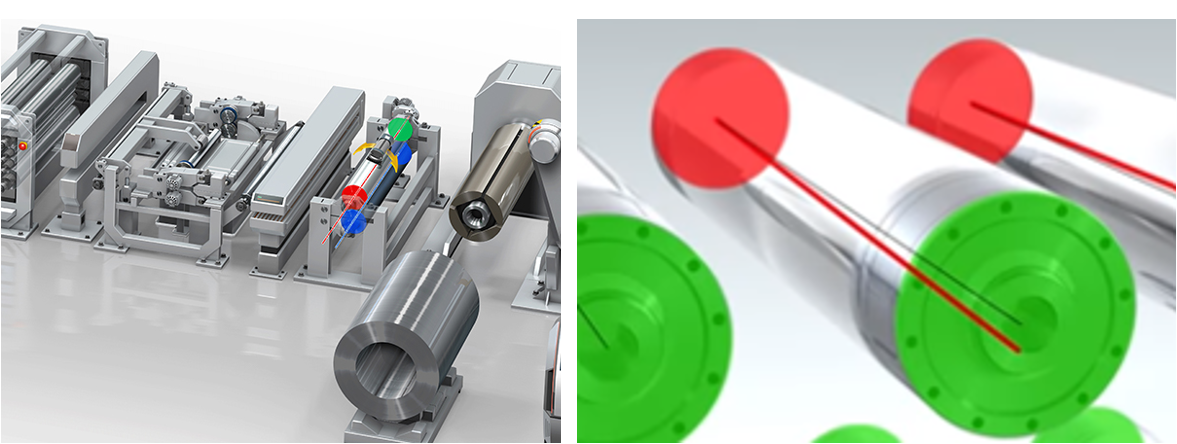

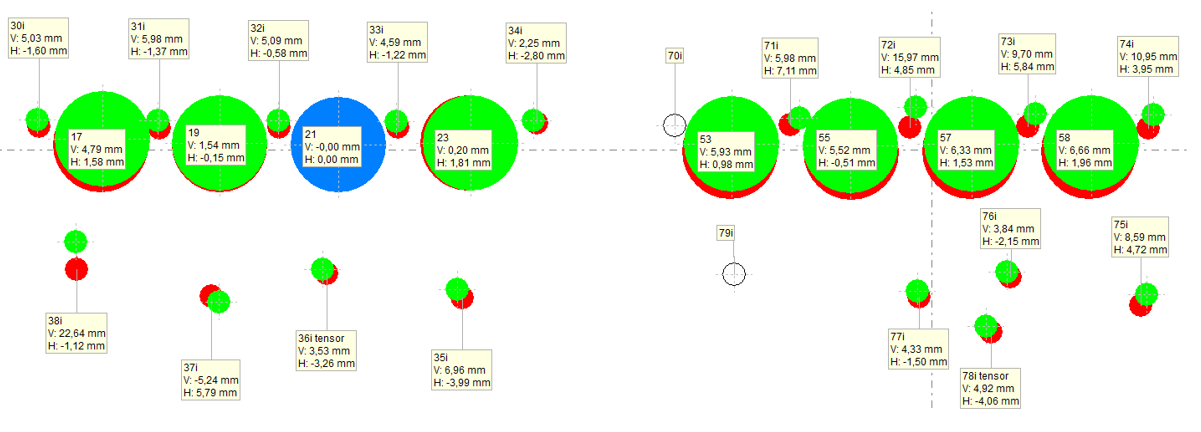

The way to present the measurements is with the observer's perspective from the operator side (represented by a green circle) towards the machine or transmission side (represented by a red circle)

Ideally, the green circle should hide the red circle, thus representing perfect alignment.

When to use PARALIGN?

Given the speed at which the rollers can be measured, around 80 or 100 rollers could be measured under normal conditions in about 8 hours. Although I have measured over 600 rollers in 12 hours at a flexible packaging printing company.

The PARALIGN is a highly recommended device in companies that do not have much time at a line stop, in a company in which alignment tolerances are very demanding, or in those that have a large number of rollers to measure.

In the same way, this equipment does not have any visual limitation, since it does not need any visual reference to carry out the measurements.

The way of reporting the rollers is shown in the following figure, where the corrections to be made, from the operator side, both horizontally and vertically with an accuracy of 0.05 mm appear for each roller.

Greetings!

Sources:

A Basic Understanding of the Mechanics of the Rolling Mill Rolls

Dr. Karl Heinrich Schröder

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more