Maintenance Categories: A Comprehensive Guide Based on ISO 14224

In the industrial sector—particularly within the petroleum, petrochemical, and natural gas industries—maintenance is far more than a routine task; it's the backbone of safety, reliability, and operational efficiency. Over the past 20 years in maintenance management, I've witnessed firsthand how a well-structured maintenance strategy can transform operations. This guide delves deep into the maintenance categories outlined in ISO 14224:2016, enriched with practical insights.

Overview of Maintenance Categories

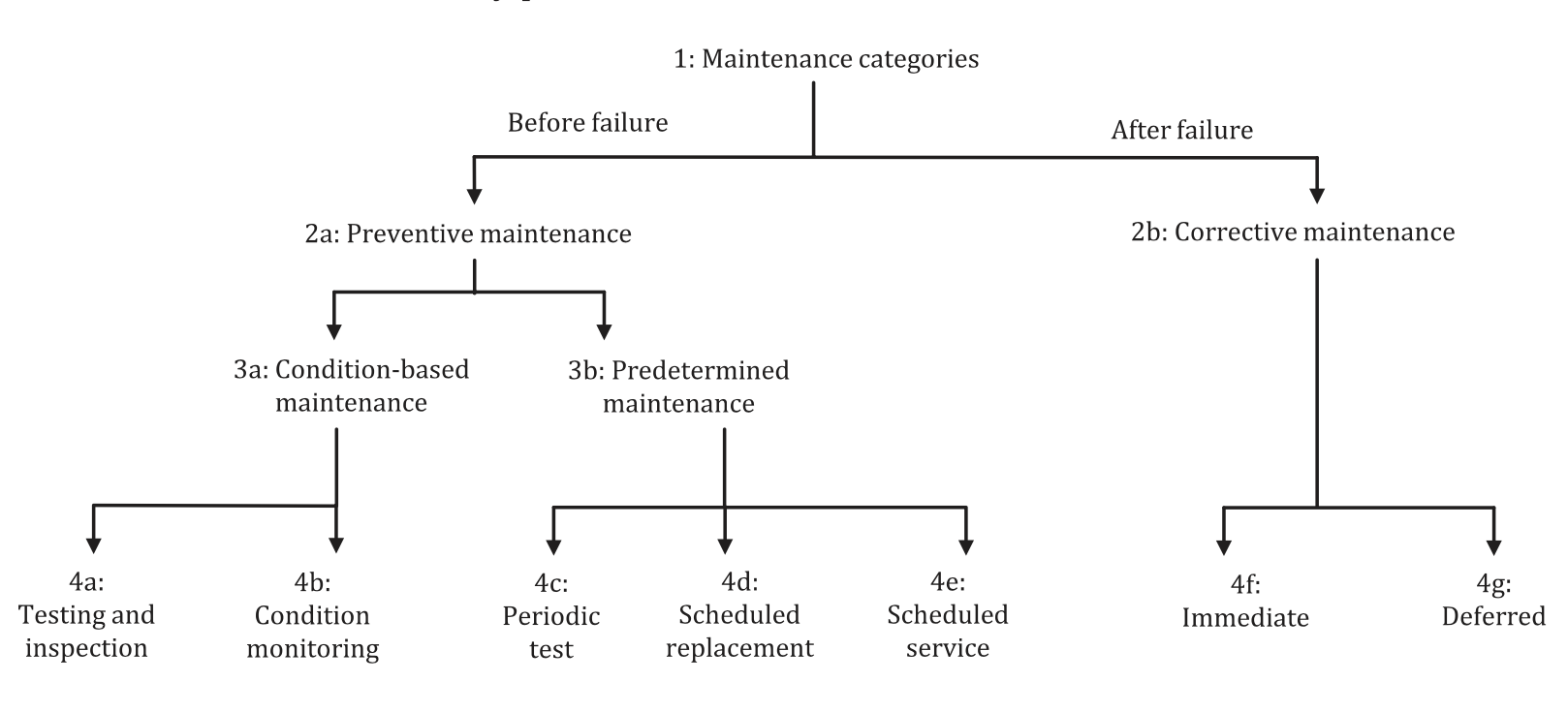

ISO 14224 offers a standardized framework for classifying maintenance activities, primarily divided into two main categories:

- Preventive Maintenance (2a)

- Corrective Maintenance (2b)

These categories help us understand when maintenance activities occur relative to equipment failure—either before (proactive) or after (reactive) an incident.

Preventive Maintenance (2a)

Preventive maintenance involves proactive measures to prevent equipment failures and ensure continuous operation. By anticipating potential issues, we address them before they escalate into significant problems, thereby safeguarding operational integrity.

Condition-Based Maintenance (CBM)

Condition-Based Maintenance is a dynamic approach that relies on monitoring the actual condition of equipment to make informed maintenance decisions. This strategy leverages real-time data and periodic assessments to detect anomalies early.

Example: In a refinery, continuously monitoring the vibration levels of compressors and pumps helps identify bearing wear or misalignment. Early detection allows for timely interventions, preventing unexpected shutdowns and costly repairs.

Another example: Utilizing thermal imaging cameras to monitor electrical panels can reveal overheating components. Identifying these "hot spots" early prevents failures that could lead to production halts or safety hazards.

Testing and Inspections (4a)

Regular testing and inspections assess both the functional performance and structural integrity of equipment. This systematic approach uncovers potential issues that aren't apparent during normal operation.

Example: Conducting ultrasonic thickness measurements on storage tanks to detect internal corrosion. In the petrochemical industry, this practice is essential to prevent leaks or catastrophic tank failures that could have environmental and safety implications.

Condition Monitoring (4b)

Condition monitoring involves the continuous or periodic assessment of equipment health using advanced diagnostic tools and sensors.

Example: Implementing oil analysis programs for critical gearboxes. By analyzing lubricant properties and detecting contaminants, we can predict wear patterns and schedule maintenance before a failure occurs.

Predetermined Maintenance (3b)

Predetermined maintenance, often referred to as scheduled or time-based maintenance, involves performing maintenance activities at set intervals, regardless of the equipment's current condition. This approach is based on statistical data, manufacturer recommendations, or industry best practices.

Periodic Tests (4c)

Conducting tests at regular intervals ensures that equipment continues to meet operational and safety standards.

Example: Testing the insulation resistance of high-voltage motors annually. This practice helps prevent electrical failures that could disrupt production and pose safety risks.

Scheduled Replacement (4d)

Replacing components based on a fixed schedule, informed by expected life cycles, prevents failures due to wear and tear.

Example: Changing out wear plates in crushers every six months to maintain efficiency in mining operations. This proactive replacement avoids unexpected downtime and maintains consistent production rates.

Scheduled Service (4e)

Routine services such as cleaning, lubrication, and adjustments are performed at predetermined times to maintain optimal equipment performance.

Example: Lubricating conveyor bearings every three months in a packaging plant. Regular lubrication prevents excessive wear, reduces energy consumption, and extends equipment life.

Corrective Maintenance (2b)

Corrective maintenance involves actions taken after a failure has occurred, aiming to restore equipment to its operational state. While it's reactive by nature, effective corrective maintenance minimizes downtime and prevents recurring issues.

Immediate Corrective Maintenance (4f)

Urgent repairs are carried out immediately after a failure that significantly impacts operations. The goal is to restore functionality as quickly as possible.

Example: Rapidly addressing a failed boiler in a power plant to restore electricity generation. Immediate action is crucial to avoid extended outages and meet energy demands.

Deferred Corrective Maintenance (4g)

Repairs that can be postponed without severely affecting operations are scheduled for a more convenient time when resources are available.

Example: Planning the repair of a non-critical HVAC unit during the next scheduled shutdown. By deferring maintenance, we optimize resource allocation without impacting immediate operational needs.

Opportunistic Maintenance

While not explicitly defined in ISO 14224, opportunistic maintenance is a practical approach where maintenance tasks are performed during unscheduled downtimes or alongside other maintenance activities. This strategy maximizes efficiency and minimizes additional downtime.

Example: During an unexpected production line stoppage, replacing components nearing the end of their life. This approach reduces the frequency of planned downtimes and makes efficient use of available maintenance windows.

Advantages and Disadvantages of Each Maintenance Type

Developing an effective maintenance strategy requires understanding the strengths and limitations of each approach.

Condition-Based Maintenance

Advantages include early failure detection, which identifies potential issues before they become critical. Optimized maintenance scheduling allows maintenance to be performed based on actual equipment condition, reducing unnecessary interventions. Cost efficiency is achieved by preventing catastrophic failures, thereby reducing repair costs and downtime.

Disadvantages involve the initial investment required for advanced monitoring equipment and training. Data management can be challenging without proper systems due to the generation and analysis of large amounts of data.

Example: Vibration analysis can detect misalignment in pumps early, preventing failure. However, setting up such systems requires investment in sensors and skilled personnel to interpret the data.

Predetermined Maintenance

Advantages are simplicity in planning and scheduling, and reduced failure risk as regular maintenance decreases the likelihood of unexpected failures.

Disadvantages include potential over-maintenance, which may lead to unnecessary work if the equipment is still in good condition, and cost implications due to routine replacement of parts that may not need it.

Example: Changing oil in generators every three months ensures reliability but may be unnecessary if the equipment hasn't been heavily used.

Immediate Corrective Maintenance

Advantages consist of quick restoration, minimizing downtime by promptly addressing failures, and being essential for critical equipment when failure halts operations.

Disadvantages are high costs due to urgent repairs often involving overtime and expedited parts shipping, and stress on personnel as emergency situations can lead to fatigue and errors.

Example: Repairing a broken conveyor belt in a mining operation immediately is costly but essential to maintain production flow.

Deferred Corrective Maintenance

Advantages include resource optimization, allowing for better planning and allocation of maintenance resources, and cost savings as deferring non-critical repairs can reduce immediate expenses.

Disadvantages involve the risk of deterioration since delayed repairs may lead to further equipment degradation, and potential safety hazards as unaddressed issues could pose risks to personnel.

Example: Postponing the replacement of a leaking valve until the next shutdown saves costs now but requires careful monitoring to prevent escalation.

Conclusion: Integrating Maintenance Strategies for Optimal Performance

In my three decades of experience, I've learned that no single maintenance strategy fits all scenarios. The key to operational excellence lies in integrating various approaches tailored to the specific needs of each asset and operation. Implementing the guidelines of ISO 14224:2016 provides a robust framework for categorizing and executing maintenance activities effectively.

Key Takeaways

Customized maintenance plans should be developed based on asset criticality, failure frequency, and operational impact. A holistic approach that combines preventive, corrective, and opportunistic maintenance ensures comprehensive asset care. Continuous improvement is essential; regularly review and adjust maintenance practices based on performance data and evolving industry standards.

Final Thoughts

Effective maintenance management is a journey of continuous learning and adaptation. It demands technical expertise, strategic planning, and a deep understanding of both equipment and people. As maintenance engineers, we bring a rich perspective that values hard work, innovation, and community. By fostering collaboration and embracing best practices like those outlined in ISO 14224, we can drive our industries toward greater efficiency, safety, and sustainability.

By integrating these maintenance strategies thoughtfully, we not only enhance equipment reliability but also contribute to the overall success and competitiveness of our industries. Let's continue to learn, share, and apply our knowledge to build a stronger, more resilient industrial future.

References:

ISO 14224:2016 - Petroleum, petrochemical and natural gas industries — Collection and exchange of reliability and maintenance data for equipment.

Mobley, R. K. (2002). An Introduction to Predictive Maintenance. Butterworth-Heinemann.

Campbell, J. D., & Reyes-Picknell, J. V. (2015). Uptime: Strategies for Excellence in Maintenance Management. Productivity Press.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more