Criticality Analysis of Industrial Assets

One of the first tasks at the moment of implementing or optimizing predictive maintenance is analyzing the criticality of industrial assets, whether they are machines, static equipment, distribution systems or electrical panels. By using the criticality analysis, we can prioritize those assets that require the highest level of monitoring and where the predictive maintenance can have the highest impact.

Criticality is mathematically defined as follows:

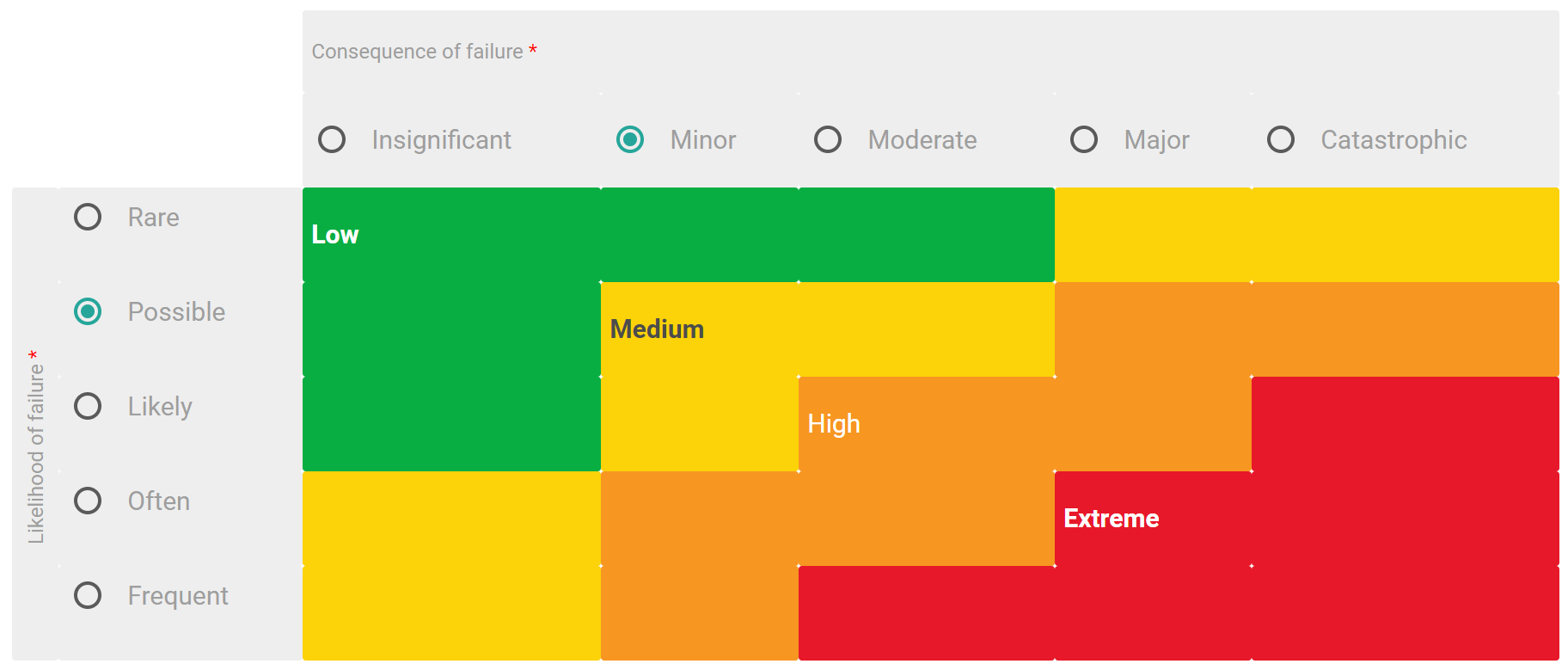

`sf "Criticality" = sf "Probability of failure" xx sf "Consequence of failure"`

The probability of failure refers to the frequency of failure of equipment. The higher the probability (higher frequency), the higher the criticality of the asset. The probability of failure has the following scales: rare, possible, probable, usual, frequent.

The consequence of the failure of the analyzed asset is determined by each plant, and it includes in a higher or lower measure the impact on the productive process, the impact on the repairing costs, and the effects on safety and the environment. The higher the consequence of the failure, the higher the criticality of the asset. The consequence of failure has the following scales: insignificant, minor, moderate, severe, catastrophic.

Depending on the probability of failure and the consequence of failure, the criticality has the following scales: low, medium, high and extreme.

The matrix of criticality is done to facilitate the criticality analysis of industrial assets.

It is important to make the criticality analysis with uniform criteria for all the assets. As the number of assets, plants, and people involved in the analysis increases, it will be necessary to standardize the scales of the probability of failure and consequence of failure with more detail.

Power-MI has a tool of criticality analysis of assets as part of its platform on the cloud of predictive maintenance where analysts and maintenance personnel interact. The analysts make their reports faster thanks to our failure catalog with the same format and with quality control. Maintenance personnel have in one single dashboard the condition of all their assets, all their reports in the same format and with their work orders ready to export to their CMMS (Computerized Maintenance Management System) or maintenance software.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more