Cosentino Digitalizes Predictive Maintenance with Power-MI

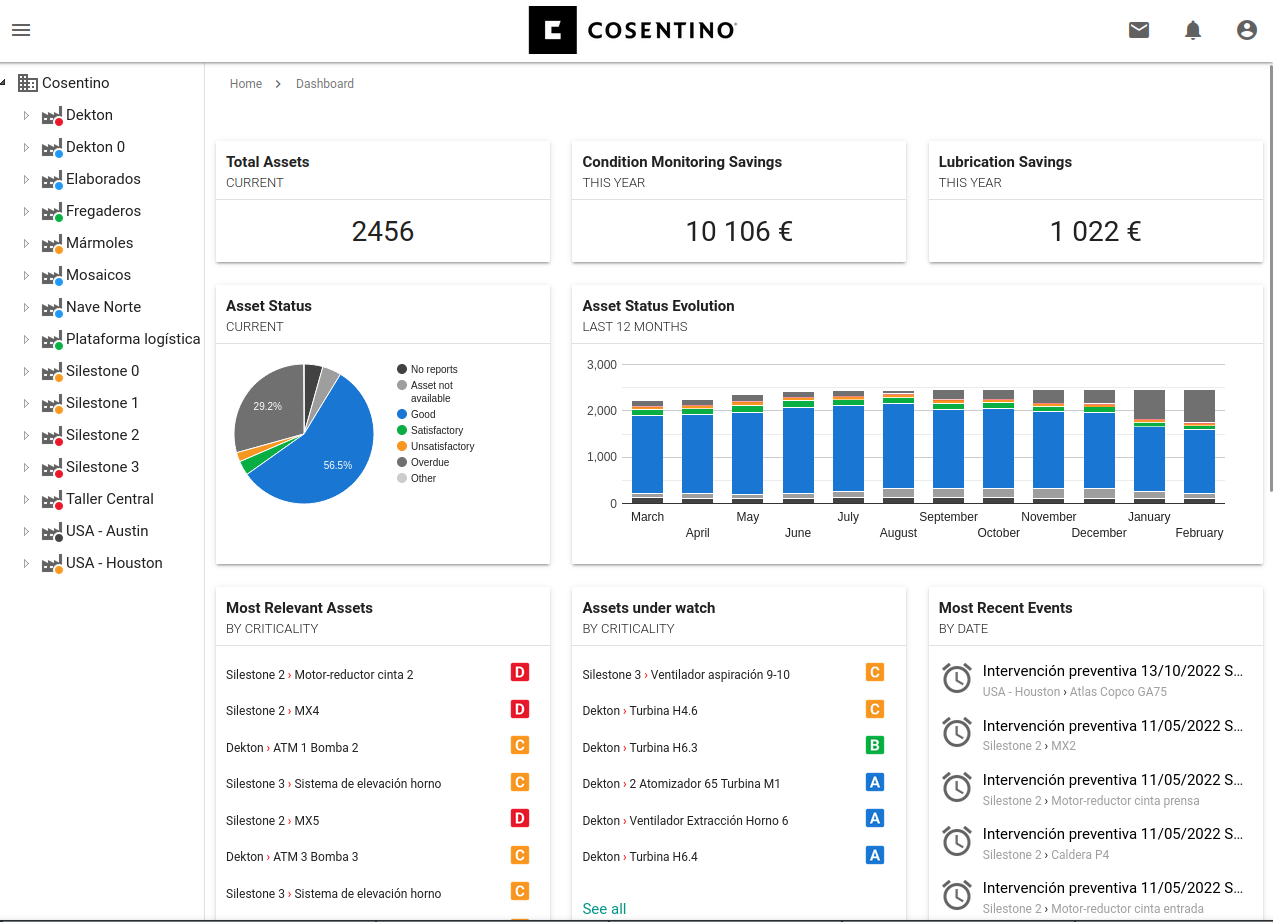

Cosentino Group, a global company in the design and architecture industry, has digitalized its predictive maintenance process with Power-MI connected to SAP PM. With over 2000 assets under predictive maintenance, Cosentino has implemented a strategic management model to maximize the impact of predictive maintenance on the company. The successful digitalization process has streamlined maintenance procedures and ensured that the company is at the forefront of innovation in the industry.

Digitalizing Current Procedures

Cosentino first documented its current procedures to streamline its predictive maintenance processes, including diagnostics, reporting, maintenance notifications, work orders, savings calculations, and failure records. The company then launched a pilot plan using Power-MI, a cloud software that provides an intuitive approach to predictive maintenance management. The pilot plan was implemented with 30 machines and produced impressive results, including faster reporting times for analysts, improved document management, failure statistics, and automatic work orders.

Gradual Implementation

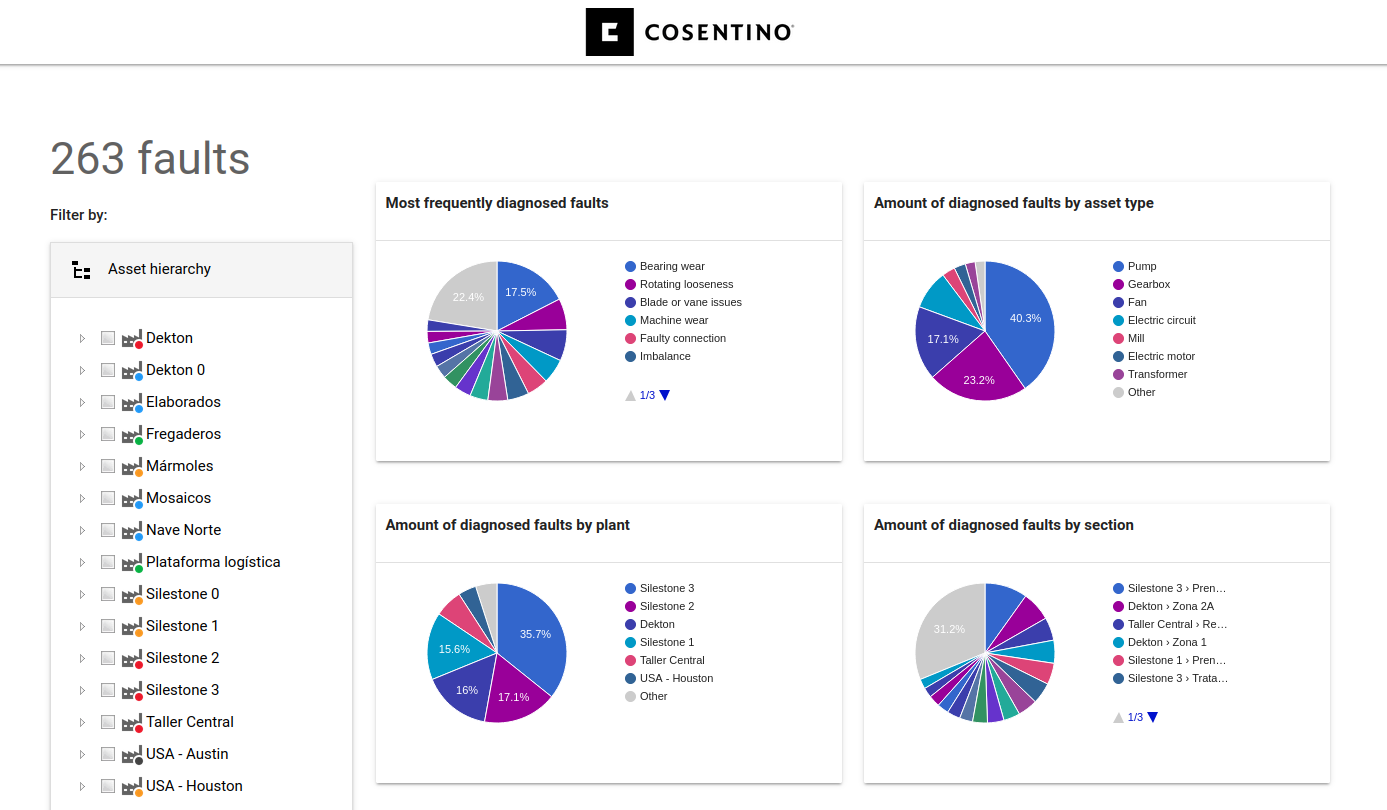

Building on the success of the pilot plan, Cosentino gradually expanded its implementation of Power-MI by adding machines and registering all relevant personnel, including service providers and maintenance and production staff. The company also added new features like route planning, analysts' calendars, and root cause analysis to enhance its predictive maintenance management. As a result, Cosentino could quantify the savings generated and renegotiate its critical machinery insurance contracts by providing visibility into predictive maintenance and demonstrating the comprehensive monitoring of all critical machines.

Connecting with SAP PM

Integrating Power-MI with SAP PM presented some challenges, as connecting a cloud service with on-site software requires strict cybersecurity protocols and authentication methods. However, after successfully connecting the two platforms via API, Cosentino was able to automate its predictive maintenance processes fully. In 2023, the company will begin condition-based lubrication and visual inspections using Power-MI mobile app. In the coming years, Cosentino aims to integrate Machine Learning and utilize asset health data in its investment decision-making.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more