The Asset Health Matrix

When predictive maintenance analysts are asked about the condition of an industrial asset, the answer varies depending on what predictive technology they have used. Many failures can be identified by various monitoring technologies. However, there are failures that can only be detected with a single technology.

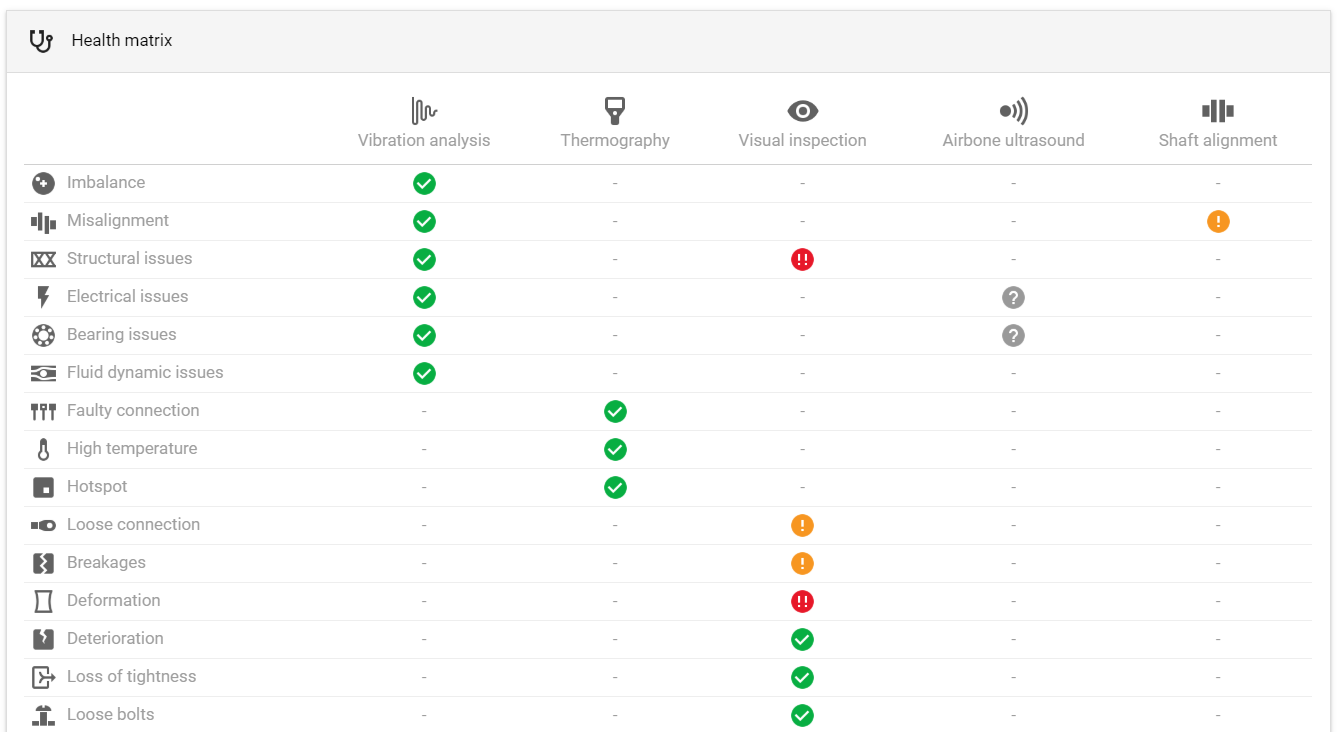

Through the asset health matrix we can visualize the condition of an asset in a concise and accurate way. But first, let's see how an asset health matrix is generated.

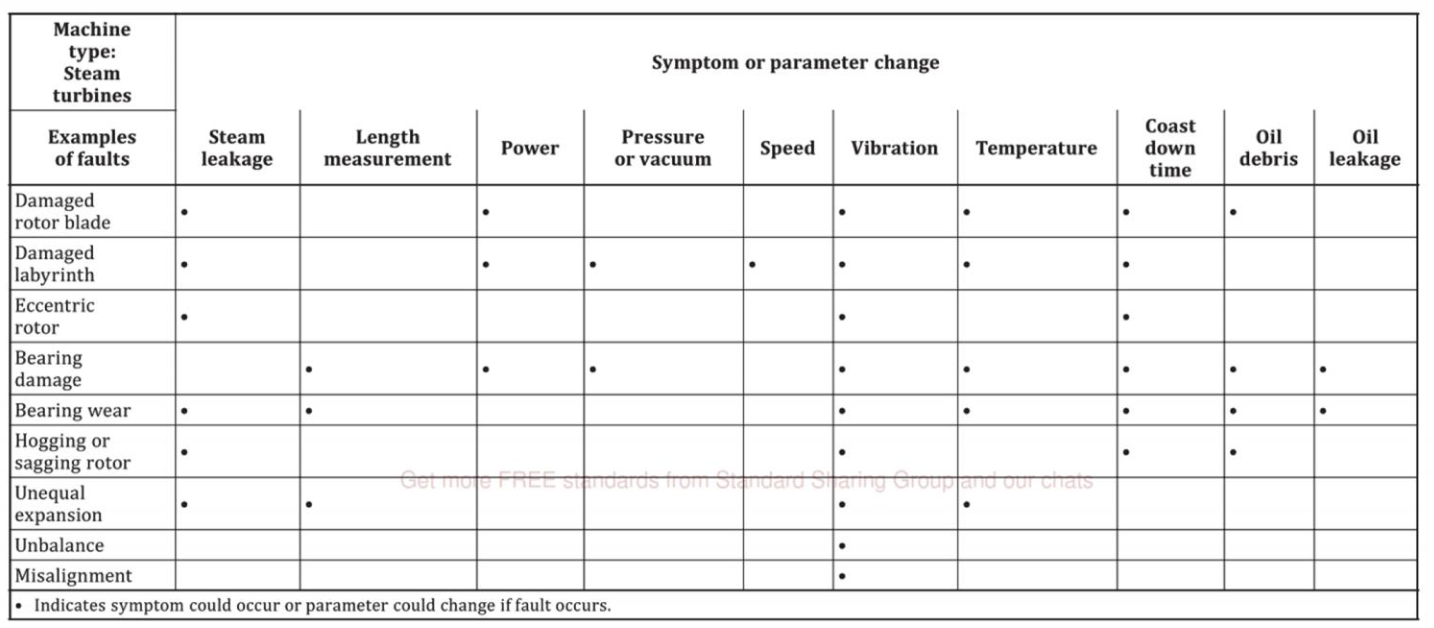

Before starting a condition monitoring program for an asset, it is necessary to identify the possible defects that each asset may have. For that we do the failure mode analysis. As a result we obtain a list of possible failures that are the basis of the predictive maintenance program that we want to manage. The maintenance managers analyze the possible failures and based on that they determine the inspections of machinery to be executed by different technologies: vibrations analysis, thermography, ultrasound, visual inspections, etc.

In making these inspections, asset analysts will report not only the overall status of the asset, but also what failures have been detected. Thus, the list of detectable failures with a predictive technology is a check-list that they must evaluate in their analysis.

ISO 17359 describes the procedure to implement a condition-based maintenance emphasizing the methodology for initial audits, implementation of monitoring, data acquisition and analysis methods. This standard proposes as a guide an asset health matrix.

This ISO standard matrix helps us to adapt the concept to our maintenance management based on the condition. Thus, if we correlate the possible failures of an asset with predictive technologies, we can generate a matrix according to our inspections.

At a glance you can see the status of the condition of a machine or any industrial asset. However, the matrix contains more information: if there is still no data, if the period for the next inspection has expired, the severity of the failure detected by the analyst.

Power-MI automatically displays the asset health matrix automatically to show the condition of the asset at a glance. This is possible thanks to managing all condition monitoring inspections on a single platform. This is essential in managing predictive maintenance.

Power-MI is a cloud platform based on Industry 4.0 that allows you to manage predictive maintenance professionally and analysts find it easy to use. Through the use of Power-MI, proper predictive maintenance management is guaranteed.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more