Introduction

In addition to the mechanical problems of machines with friction bearings such as imbalance, misalignment, bent shaft, eccentricity, resonance, etc. There are some problems or defects typical of the friction bearings such as excessive clearance, oil whirl and inadequate lubrication.

Excessive clearance

In order for a looseness problem to manifest it is necessary the presence of excitation forces due to imbalance, misalignment, etc. that excite the problem, resulting in high levels of vibration. An overloaded bearing is less capable of absorbing forces due to mechanical problems and results in high vibration levels at 1x, 2x RPM and higher harmonics. Half harmonics (1.5x, 2.5x, 3.5x RPM, etc.) and subharmonics (0.5x RPM) can also appear, as discussed in the chapter on looseness. Looseness conditions the position of the shaft within the bearing, so that excessive clearance can lead to incorrect positioning, and consequently, to a phenomenon of misalignment, with the appearance of vibration and frequencies characteristic of this problem.

Oil whirl

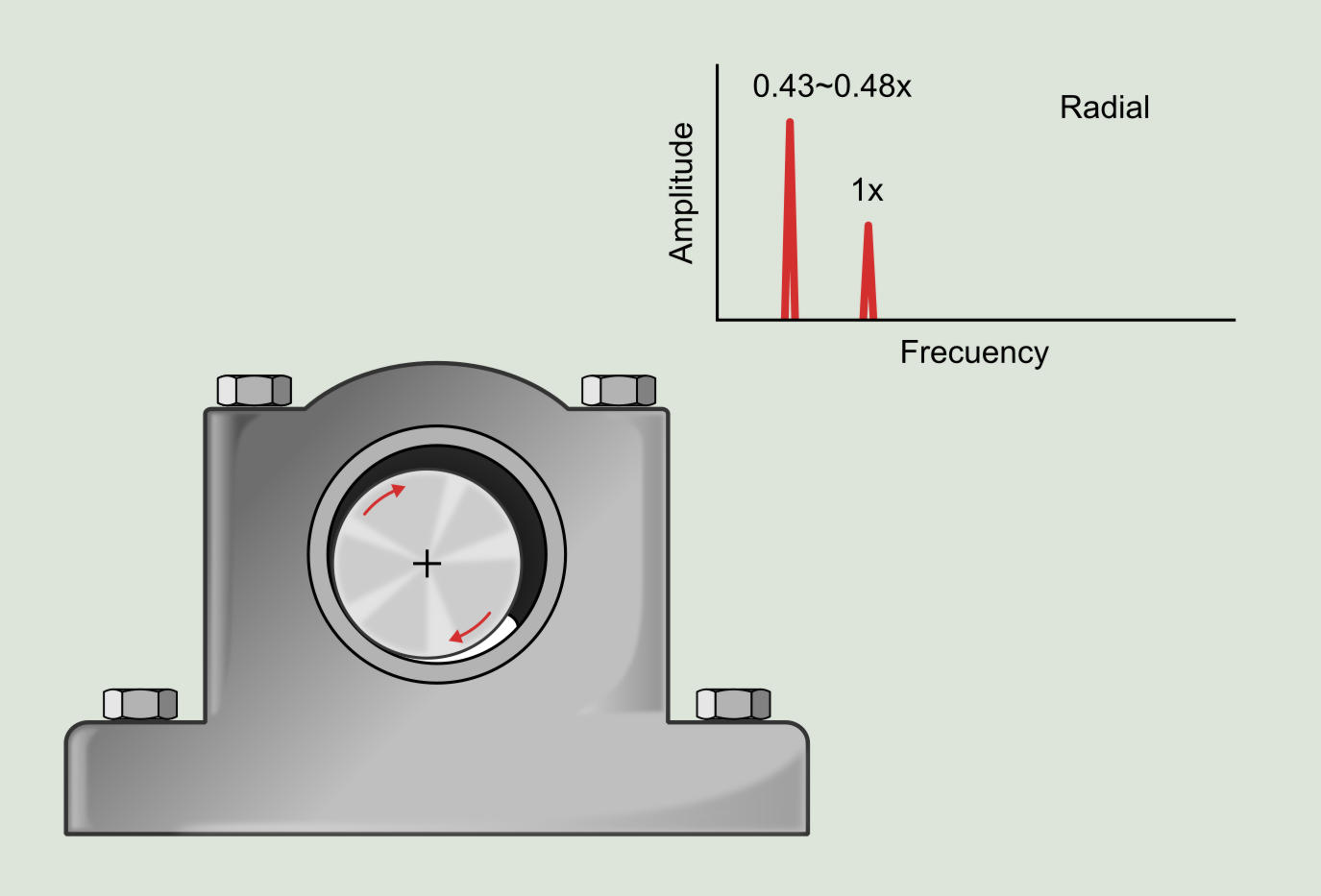

Oil whirl is a typical plain bearing problem. This problem occurs primarily in machines with bearings equipped with high pressure lubrication systems and high operating rotational speeds, usually above the critical speed of the rotor. The typical vibration associated to the oil whirl is subsynchronous, presenting in the spectrum a frequency in a range between 0.43 and 0.48x RPM, being able to produce catastrophic failures if the rotor turning speed is two times one of the critical speeds, due to the excitation of the natural frequency of the rotor. This phenomenon is known as oil whip.

Down below we will describe a little more in detail the phenomenon of the oil whirl in plain bearings. Under normal operating conditions, the rotor is located within the bearing at an eccentric position on an oil film. The rotating movement of the shaft pumps oil creating a high pressure wedge that supports the shaft load. Downstream the pressure the fluid goes through is lower than upstream. This pressure difference causes a tangential force on the shaft in the direction of rotation which is the cause of the rotor vibration. The typical value of the characteristic frequency of this movement is directly related to the dragging speed of the fluid film. Indeed, like all moving viscous fluids, the molecular layer of oil in contact with the rotor moves at its speed, while the adjacent layers are drawn by shear forces until the layer adjacent to the bearing wall that has zero speed. Normally, the forces produced by this phenomenon are small compared to the static or dynamic loads acting on the bearing. However, sometimes such oil swirling forces are the main ones, and hence the danger of this phenomenon.

This, together with the fact that the defect is unstable, means that it has to be treated with special attention, analyzing all the possible root causes that originate its appearance.

The oil whirl phenomenon is often related to an inadequate bearing design. For example, if the static load of the shaft in the bearing is too light then the force generated by the rotation of the oil film may be the dominant force, in which case the machine will be very susceptible to suffer oil whirl. Excessive bearing wear is a problem that contributes to oil whirl. The tendency of the machine to develop oil whirl depends on the amount of eccentricity of the shaft within the bearings. However, in a worn bearing, the shaft will turn more and more eccentric, increasing bearing wear and therefore increasing the likelihood of oil whirl. An increase in oil pressure or in viscosity can also increase the chances of oil whirl issues. When an oil whirl problem is found, temporary solutions can be applied to correct it, such as: increasing the oil temperature so that the viscosity decreases or increasing the bearing load by introducing a small imbalance or misalignment. At present there are special bearing designs aimed at reducing the chances of appearance of oil whirl.

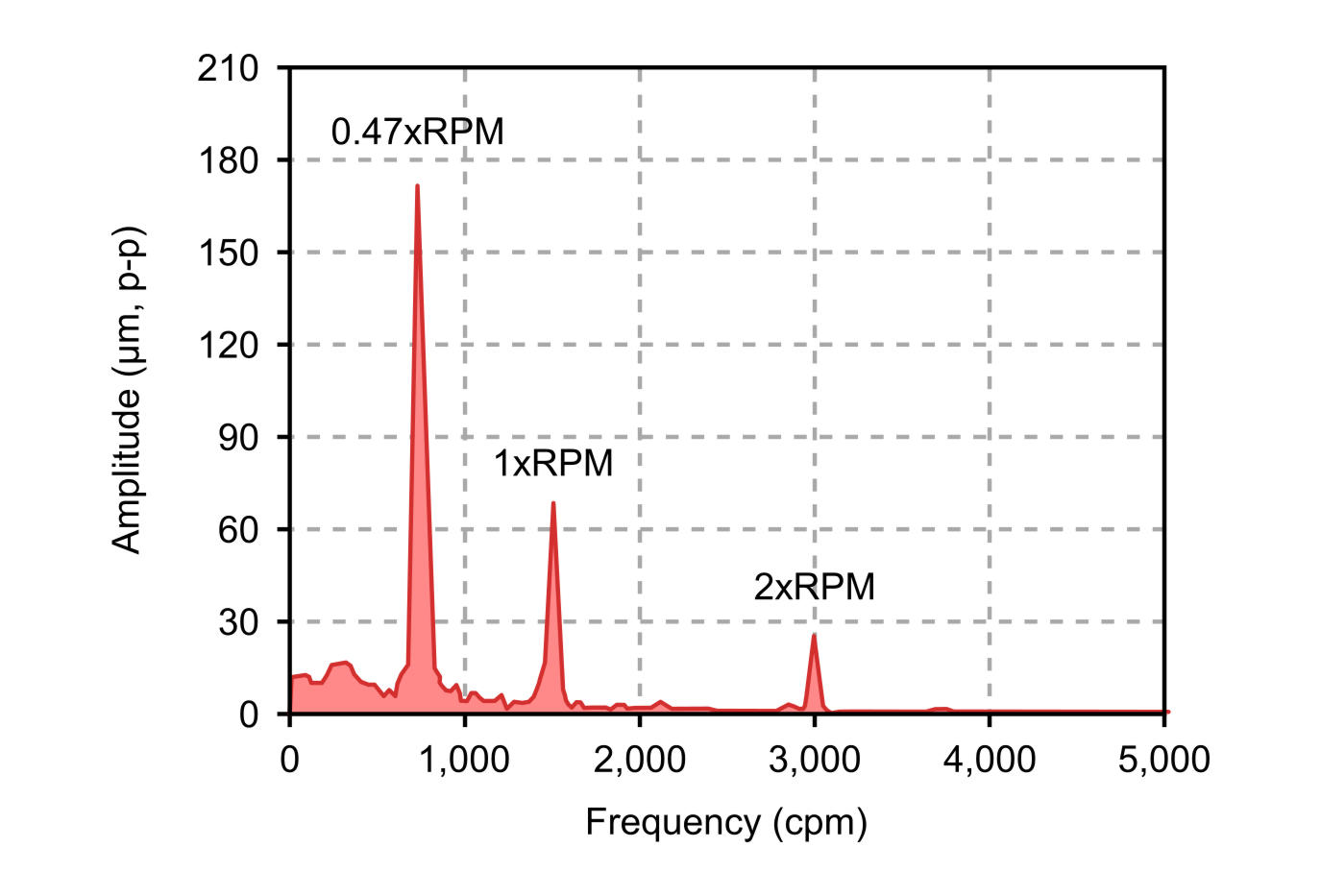

In the following figure we present a characteristic spectrum of an oil whirl problem. The spectrum was taken by connecting to the continuous monitoring system front panel buffered output of a nuclear power plant refrigeration vertical pump, and a dominant peak was observed at 0.47×RPM. During the data collection it was observed how the amplitude of the peak amplitude was very variable, characteristic that shows the instability of the phenomenon itself.

Inadequate lubrication

When the lubrication system fails or the oil used is not the adequate, the rotor can reach the bearing wall producing fricction and originating a tangential vibration as in the previous case, but conceptually different and also at a very different frequency, generally high and unrelated with the RPM of the machine.

cloud_download

cloud_download