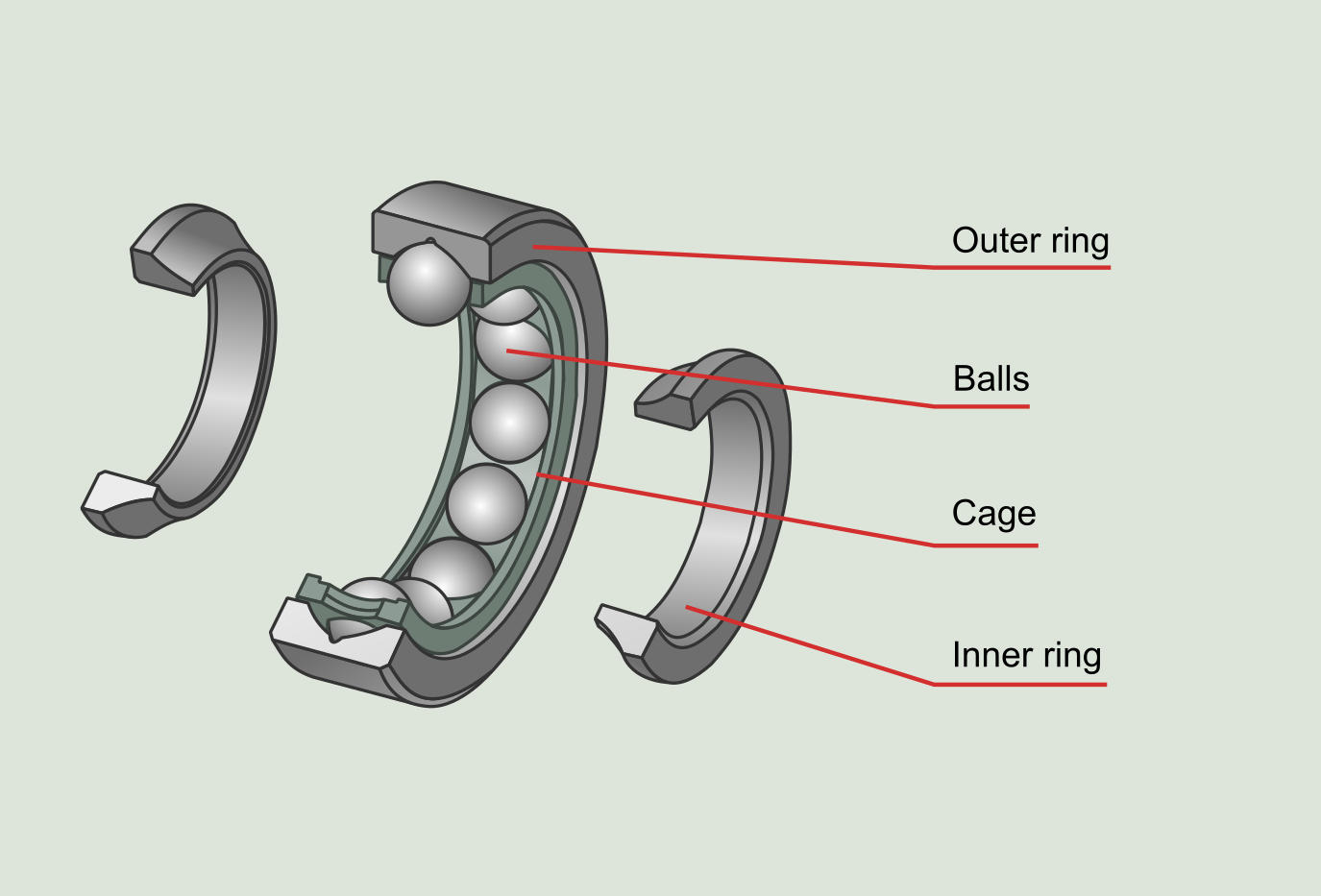

Rolling element bearings consist of several clearly differentiated components: inner race, balls or rollers, cage and outer race.

The deterioration of each of these elements will generate one or more characteristic failing frequencies in the frequency spectra that will allow us a quick and easy identification. The four possible bearing failing frequencies are:

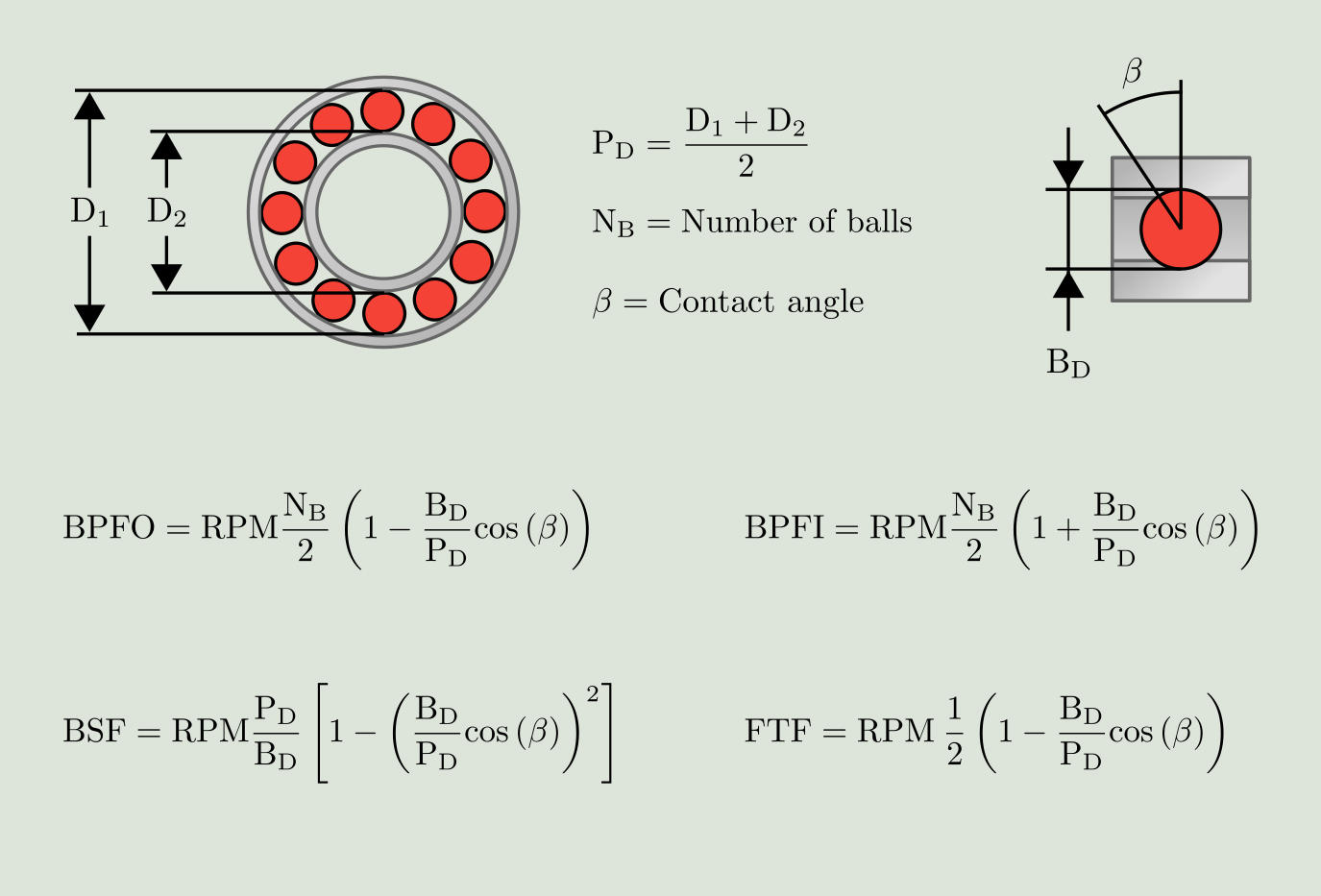

- BPFO (Ball Pass Frequency Outer) or outer race failing frequency. Corresponds physically to the number of balls or rollers that pass through a given point of the outer race each time the shaft makes a complete turn.

- BPFI (Ball Pass Frequency Inner) or inner race failing frequency. Corresponds physically to the number of balls or rollers that pass through a given point of the inner track each time the shaft makes a complete turn.

- BSF (Ball Spin Frequency) or rolling element failing frequency. Corresponds physically to the number of turns that a bearing ball or roller makes each time the shaft makes a complete turn.

- FTF (Fundamental Train Frequency) or cage failing frequency. Corresponds physically to the number of turns that makes the bearing cage each time the shaft makes a complete turn.

Formulas for the calculation of the bearing failing frequencies

Each bearing has its own geometric characteristics from which we can determine its failing frequencies. These frequencies will appear in the spectral signatures when the bearing is deteriorated, and the formulas for its calculation are shown in Figure 9.2. For most bearings these failing frequencies will not be integer numbers, so that the dominant vibration, when there is a defect in any of the bearing components will be non-synchronous (not coincident with rotating frequency harmonics).

When one of the bearing components is damaged, we will distinguish in the frequency spectrum the fundamental frequency corresponding to the damaged element, always accompanied by harmonics. In those cases where the bearing physical parameters are not known, there are some empirical formulas that will allow us to determine the failing frequencies of the bearing races and the cage in function of just the number of rolling elements and the rotating speed:

`sf "BPFO" = sf "0.4" xx sf "N"_sf "B" xx sf "RPM"`

`sf "BPFI" = sf "0.6" xx sf "N"_sf "B" xx sf "RPM"`

`sf "FTF" = sf "0.4" xx sf "RPM"`

Influence of the variation of the contact angle in the bearing failing frequencies

Bearing failing frequencies, according to the mathematical formulas expressed above in Figure 9.2, depend on the contact angle, hence any slight variation of this will result in a variation of the ideal bearing failing frequencies, making it difficult to identify these frequencies in the spectrum. The possible causes that can produce a variation of the contact angle can be very diverse: misalignment, thermal growth, excessive bolt tightening, pitting or peeling in the bearing races, etc. All this will influence these precalculated frequencies (ideal frequencies) so that they do not exactly coincide with the frequencies that appear in the spectrum (actual frequencies), and therefore in some cases a certain level of margin must be allowed in the identification of the failing frequencies.