Visual inspections application for predictive and Condition-Based Maintenance

Unlocking the power of visual inspections in predictive maintenance

Visual inspections are the most fundamental, intuitive, and easy-to-implement technique in an industrial plant's condition-based maintenance (CBM) strategy. Visual inspections play a crucial role in CBM, involving monitoring equipment performance and asset management to determine the most cost-efficient time for maintenance. They are used to identify issues with assets before they worsen, informing preventive maintenance tasks, eliminating downtime, and decreasing unnecessary costs. In CBM, visual inspections are combined with other condition monitoring techniques like vibration, ultrasound, oil analysis, and thermography to collect data on asset conditions. Visual inspections are also integral to predictive maintenance, making them a critical tool for maintenance professionals.

[1] Design your visual inspections in Power-MI

Configure inspection parameters for fieldwork

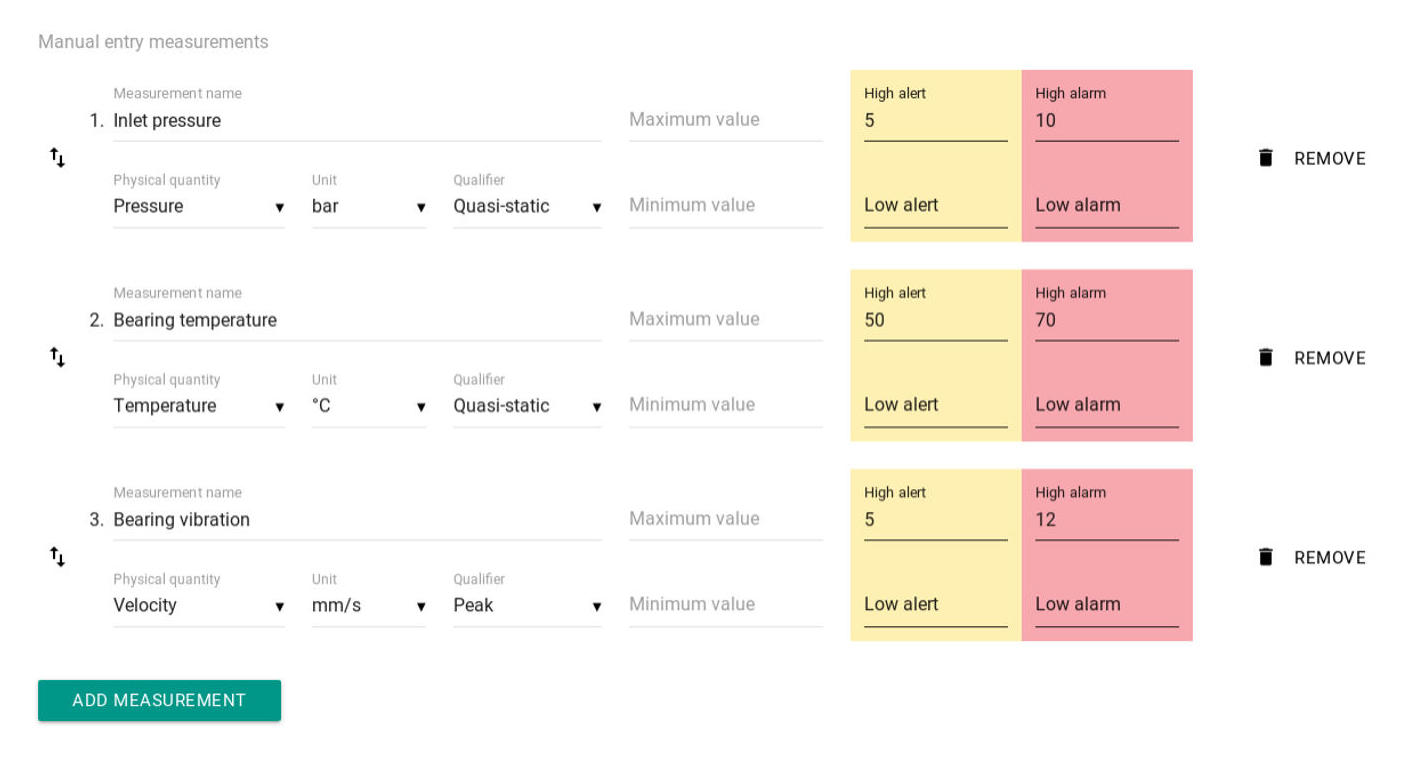

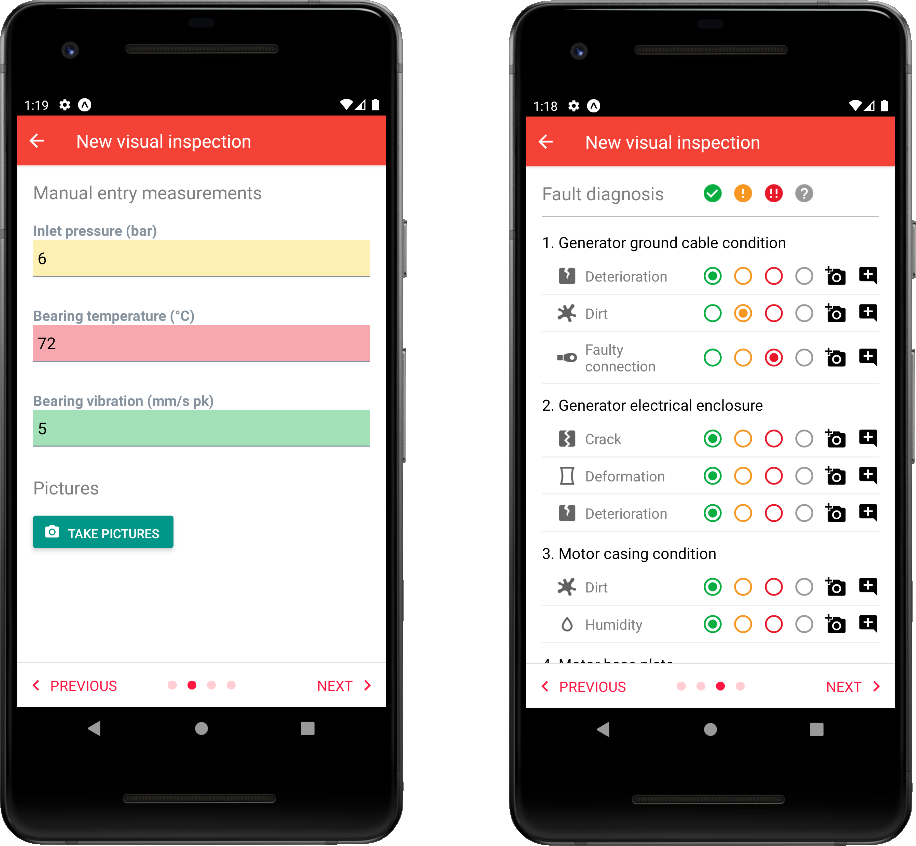

Set up the parameters that the inspector will need to gather in the field. You can configure any magnitude, type of parameter, and alarm levels, allowing the inspector to fill in the information quickly and see on the spot if the parameter is in alarm or not.

Create inspection guidelines with checkpoints and detectable failures

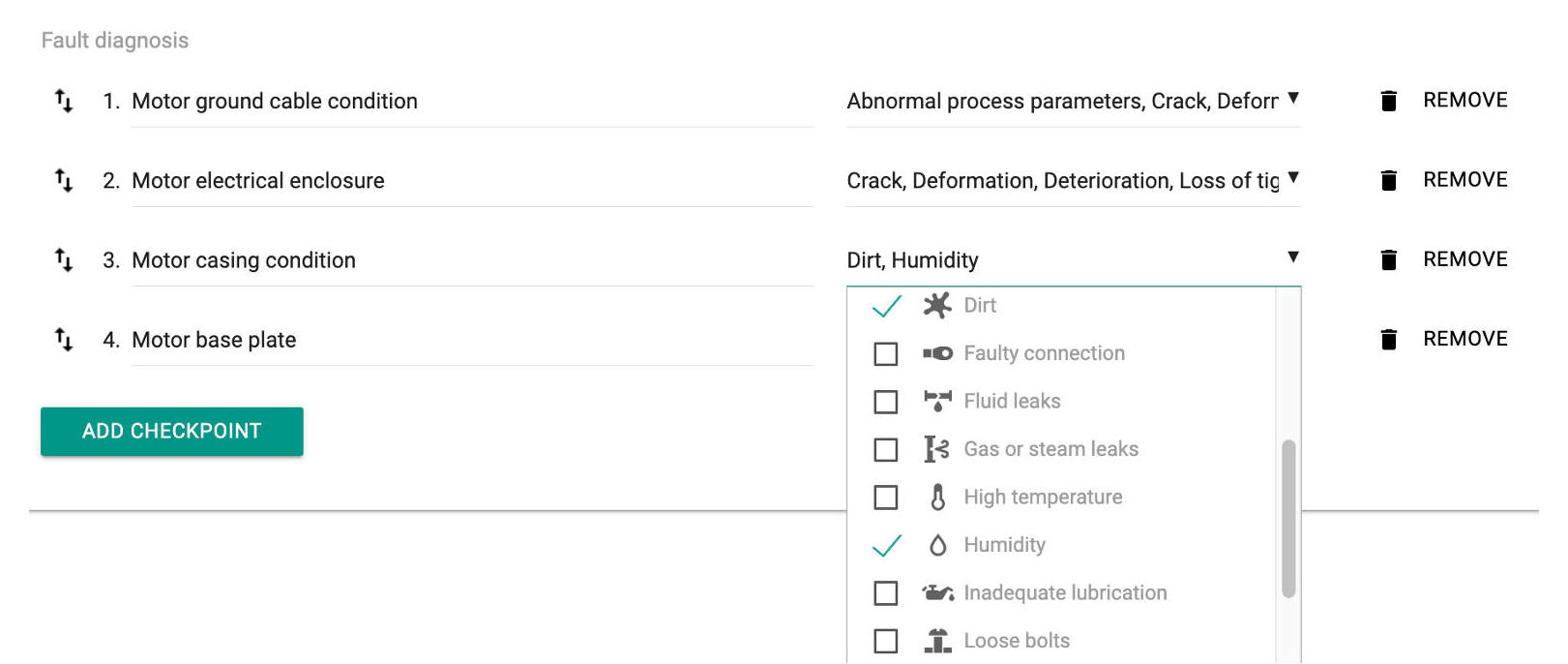

Design your inspection guidelines by establishing checkpoints and possible detectable failures. This facilitates the inspector's work by providing a clear check-list to follow during the inspection.

Establish workplace hazards for inspection locations

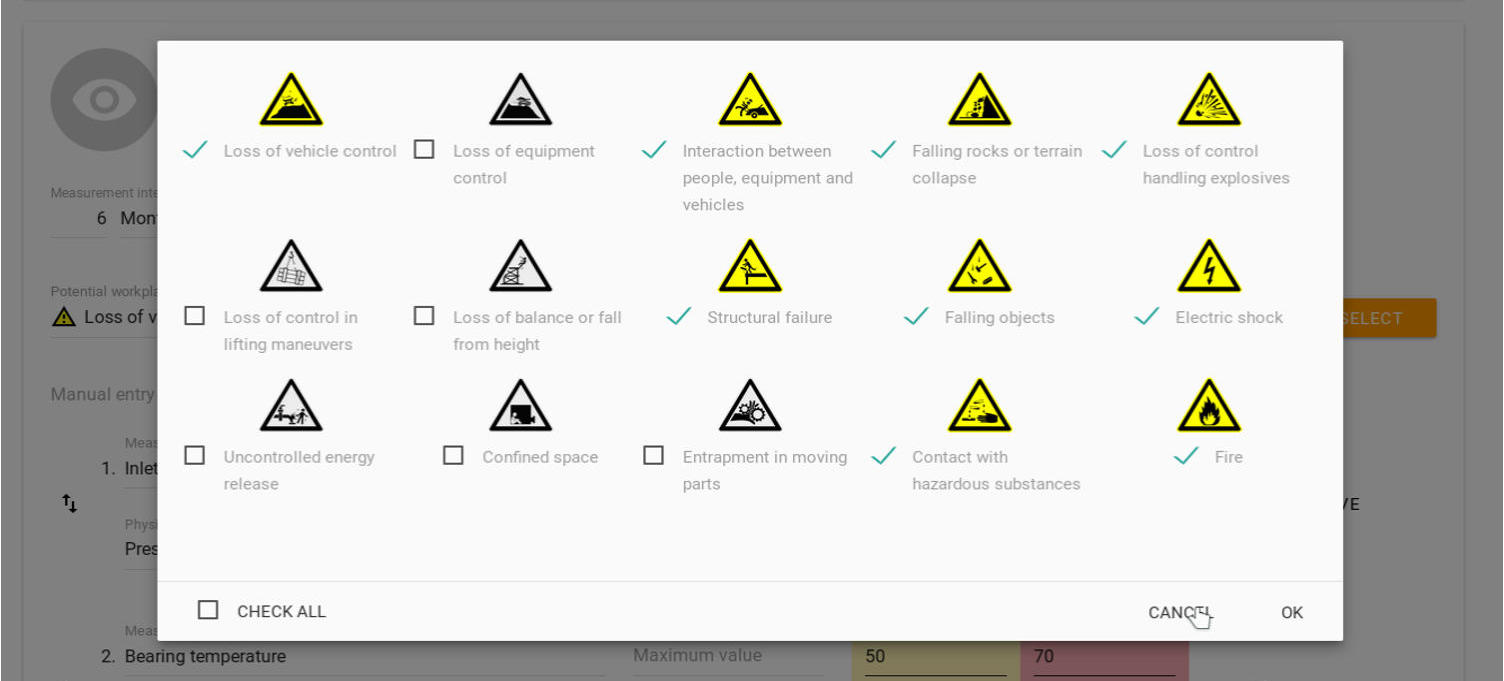

Define the occupational risks of the inspection site to ensure that the inspector is always working safely and is informed of the risks they may be exposed to during the inspection.

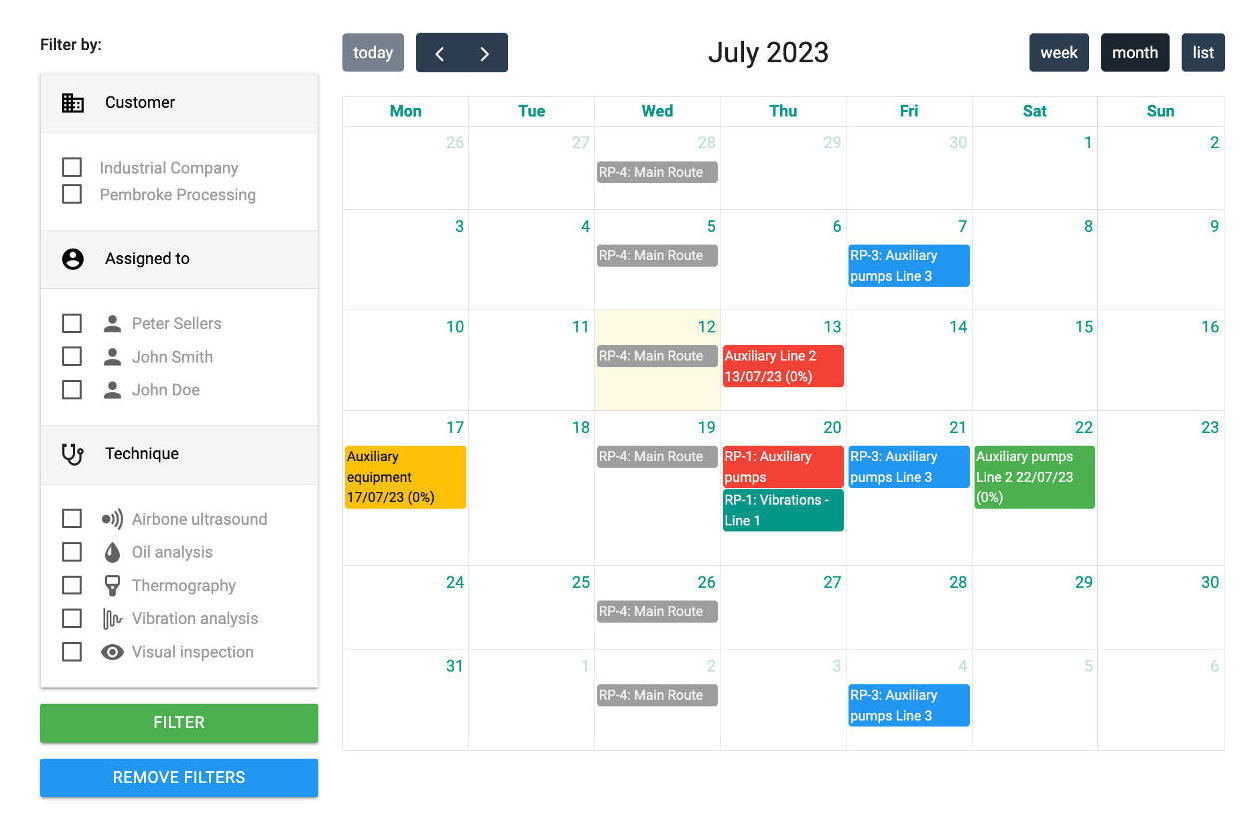

Visual inspections routes and scheduling

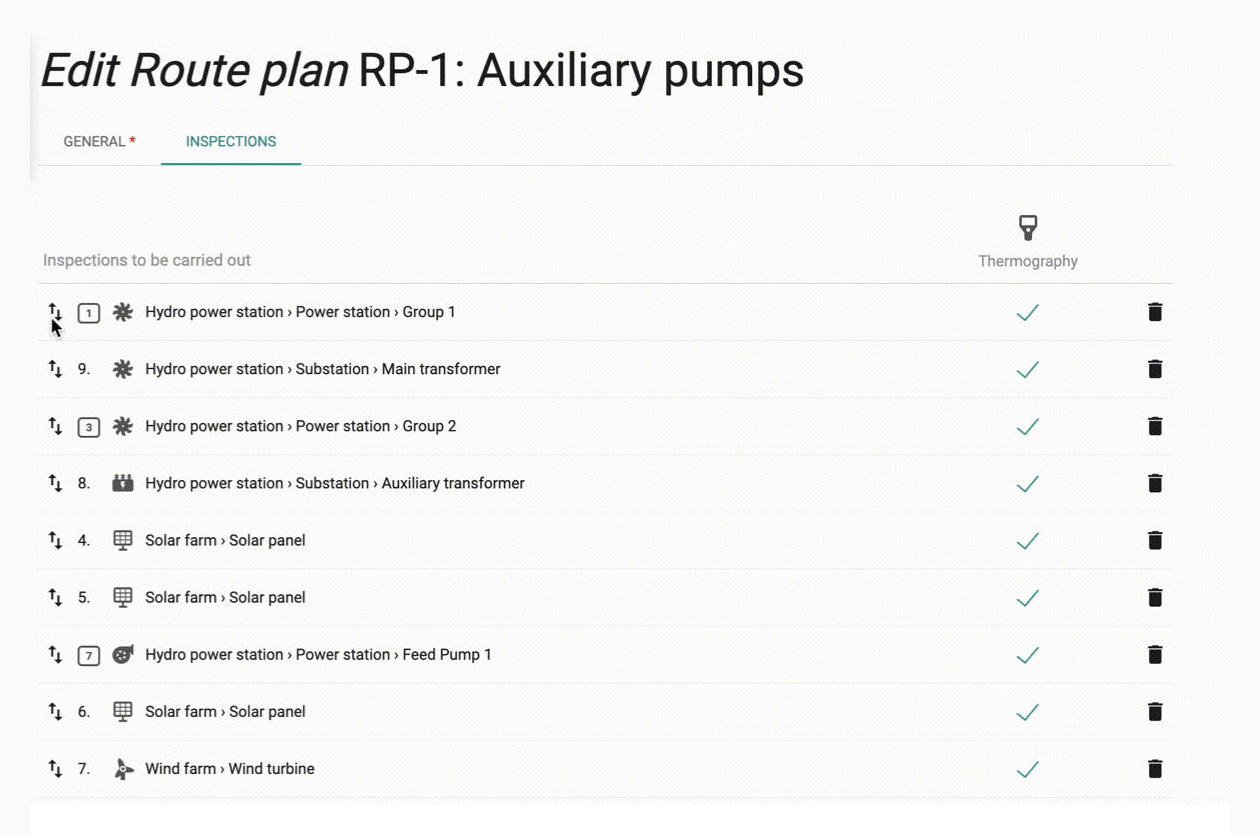

Manage inspection routes, inspector calendars, and report logs.

[2] Execute visual inspections with the mobile app

Power-MI is synchronized in real-time with the mobile phone and tablet application, enhancing the efficiency and effectiveness of visual inspections.

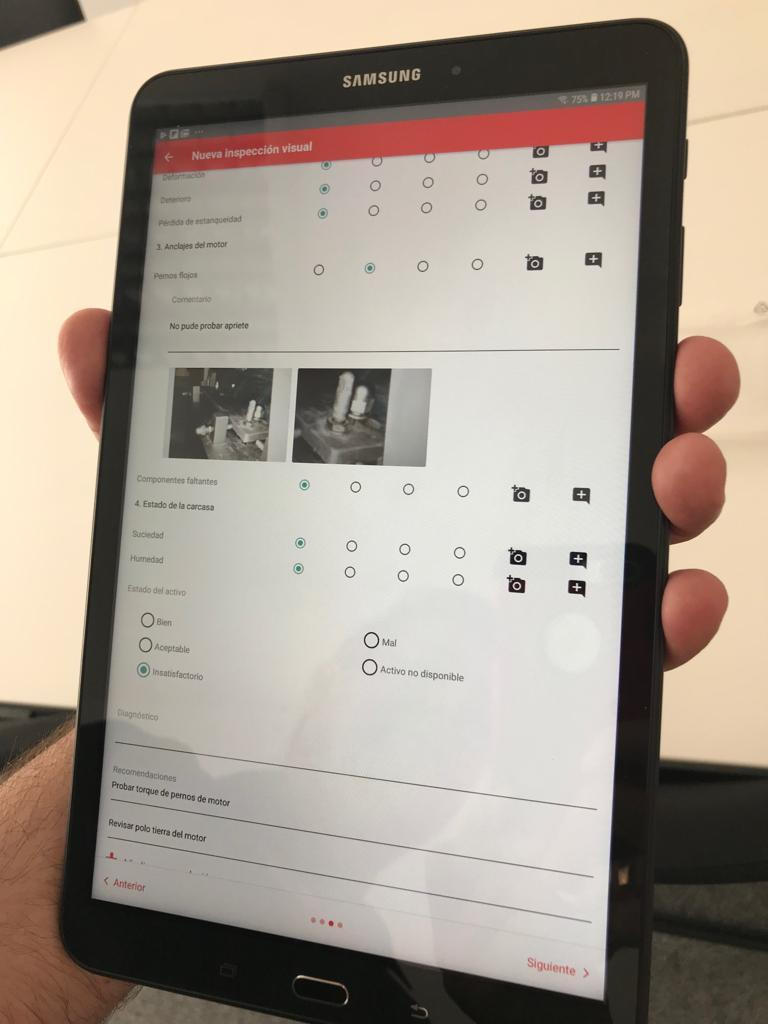

Agile information and data collection with user-friendly interface

Inspectors will appreciate the application's easy-to-use interface for quick and efficient data collection. Simplicity is key, making the inspection process smooth and enjoyable.

Mobile visual inspections app for Android and iOS

Whether on a cell phone or tablet, the Power-MI application is compatible with Android and iOS platforms. The offline functionality ensures uninterrupted work, even without an internet connection.

Risk prevention in visual inspections

Safety is paramount. The application provides in-app risk warnings and detailed information about the inspection location, ensuring that inspectors are aware of potential hazards and can take necessary precautions.

Photo acquisition and synchronization in visual inspections

Capture the evidence you need right on the spot. The application allows in-situ photo capture of detected failures during inspections, seamlessly integrating these images into the report for comprehensive documentation.

[3] Integrate visual inspections into your Condition-Based Maintenance

Seamlessly incorporate visual inspections into your existing condition-based maintenance strategy with Power-MI's advanced features.

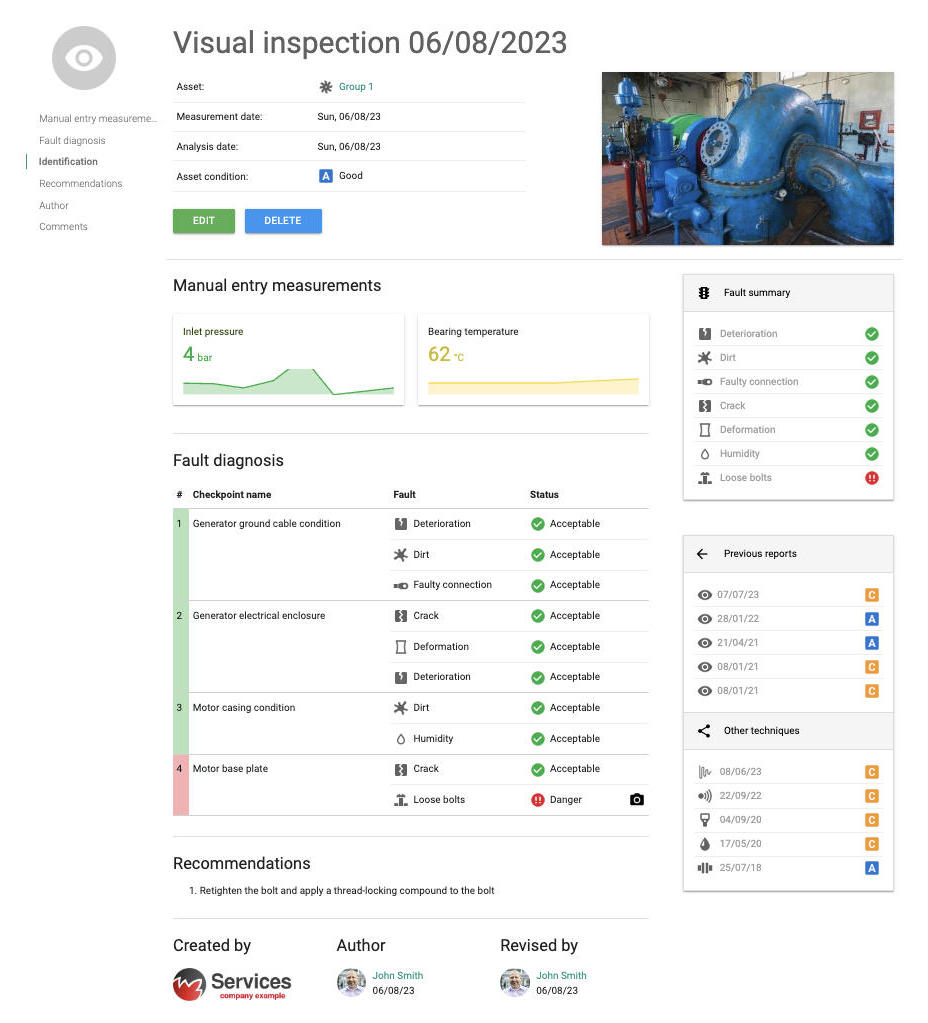

Automatic cloud reporting for visual inspections

Simplify your reporting process with automatic report generation from the data and information inputted by the inspector. This feature ensures consistency and saves valuable time.

Standardized visual inspections criteria and format

Maintain uniformity across all inspections with standardized criteria and format. This standardization ensures that every inspection is conducted according to the same set of guidelines, enhancing the reliability of the results.

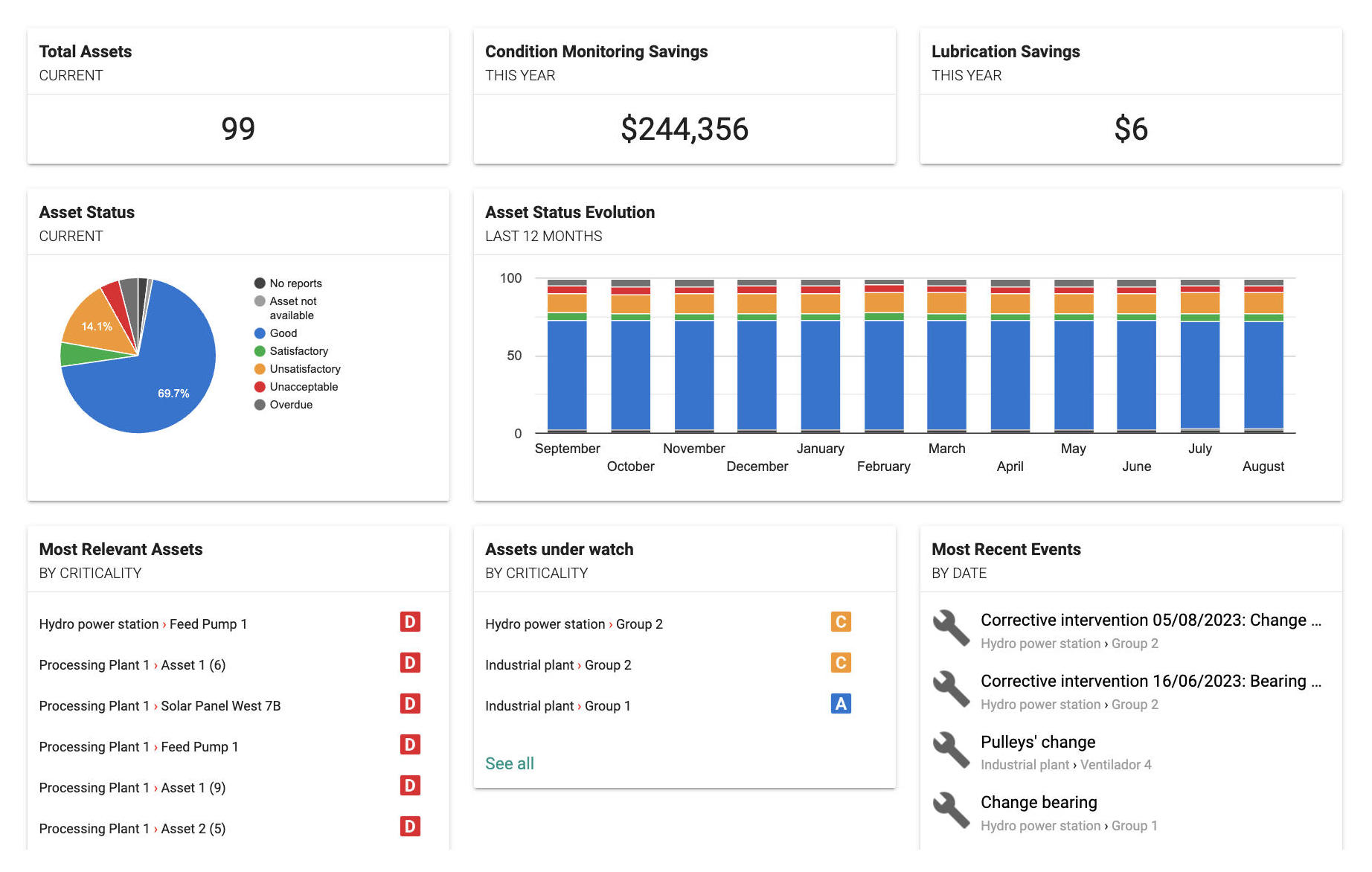

Live KPIs for visual inspections

Stay informed with real-time Key Performance Indicators (KPIs) synchronizing with predictive maintenance data. This live tracking allows for immediate insights and more informed decision-making.

Integration with CMMS for visual inspections

Integrating visual inspections with your existing maintenance software, CMMS, or ERP via API ensures a smooth workflow. This integration facilitates a more cohesive maintenance strategy, aligning visual inspections with other maintenance activities.

Benefits of managing visual inspections with Power-MI

-

done

Easy setup and user-friendly interface

Simplify your inspection process with an intuitive interface that requires minimal training, making it easier for your team to get started.

-

done

Integrate visual inspections into your predictive maintenance strategy

Seamlessly incorporate data, information, failure records, and workflows from visual inspections into your predictive maintenance process for a more cohesive maintenance strategy.

-

done

Increase productivity with visual inspections app

Efficiently manage your inspectors and streamline workflows, allowing your team to accomplish more in less time.

-

done

Cost-effective condition monitoring with visual inspections app

Leverage visual inspections as a key component of your broader maintenance strategy to reduce costs through early issue detection, preventive maintenance, and quality assurance.

-

done

Safety and quality assurance in visual inspections

Ensure compliance and safety with a formal, documented process for visual inspections, reducing risks and enhancing the quality of your maintenance activities.

Get visual inspections application