Below are the most typical bearing defects and their identification in the frequency spectrum:

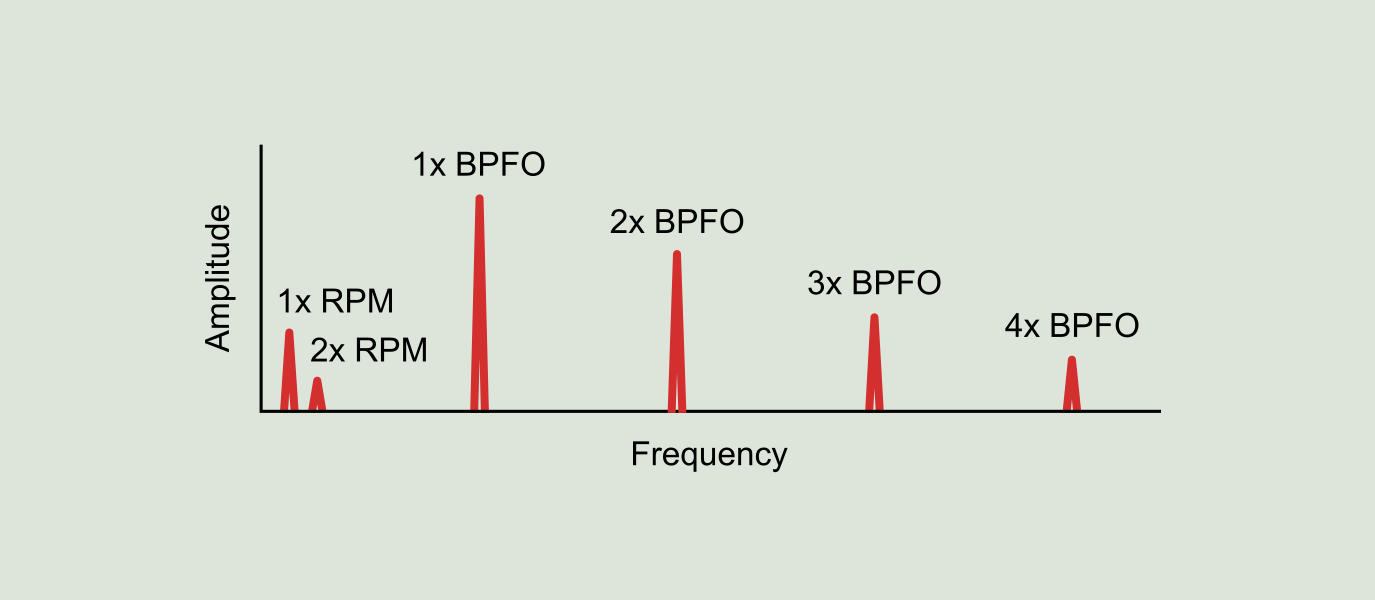

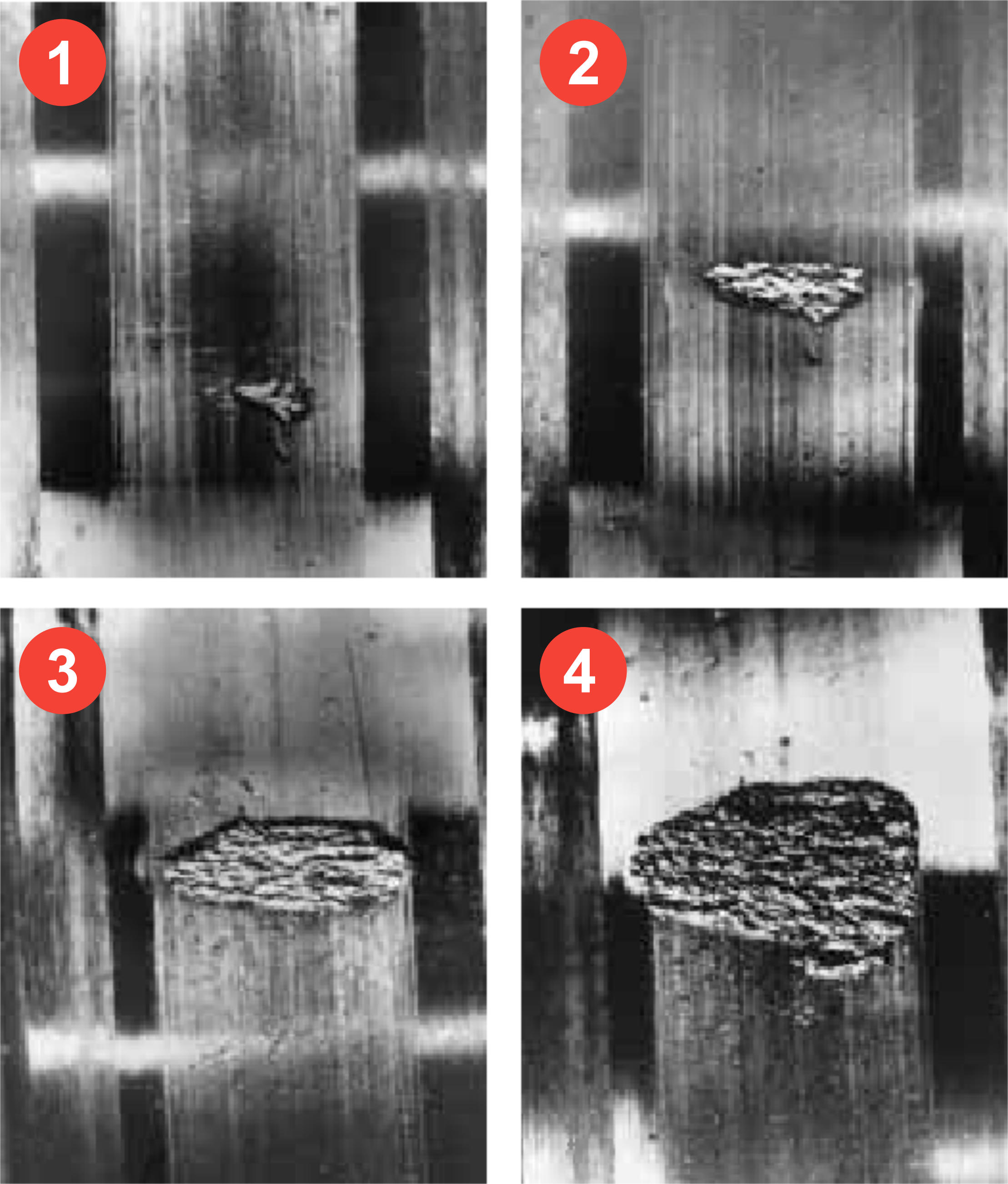

- Outer race defects: the spectrum is characterized by the presence of harmonic peaks of the outer race failing frequency (between 8 and 10 harmonics of the BPFO).

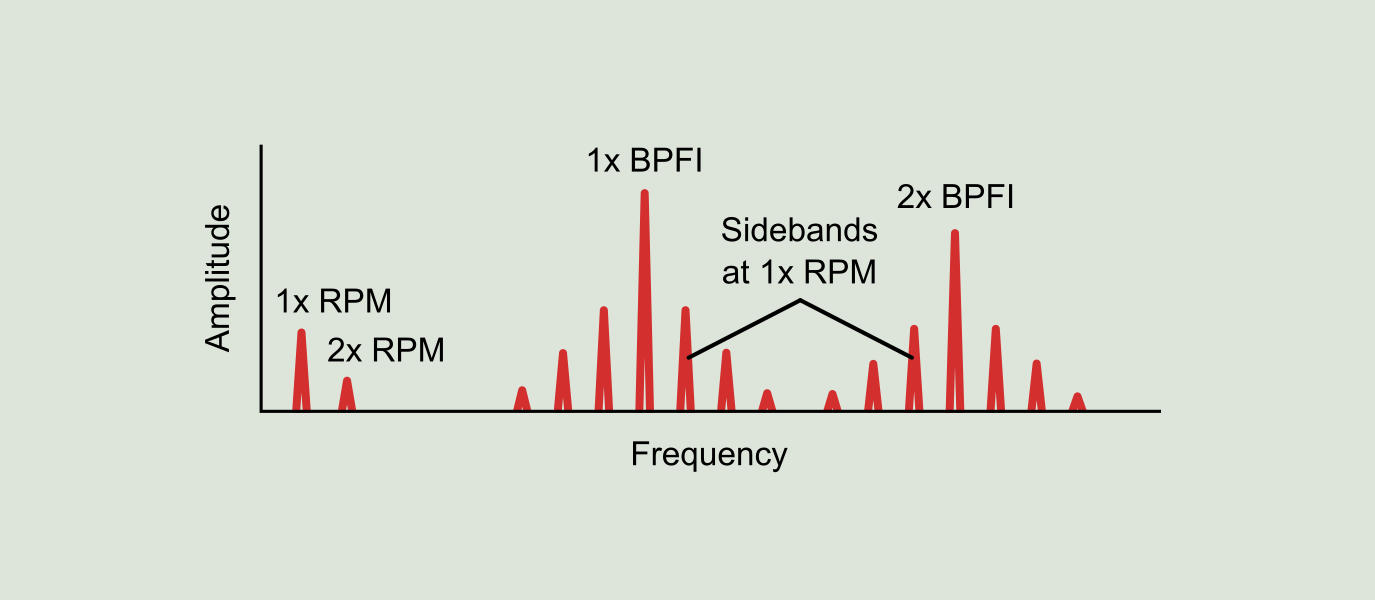

- Inner race defects: the spectrum shows several harmonic peaks of the inner race failing frequency (usually between 8 and 10 BPFI harmonics) modulated by sidebands at 1x RPM.

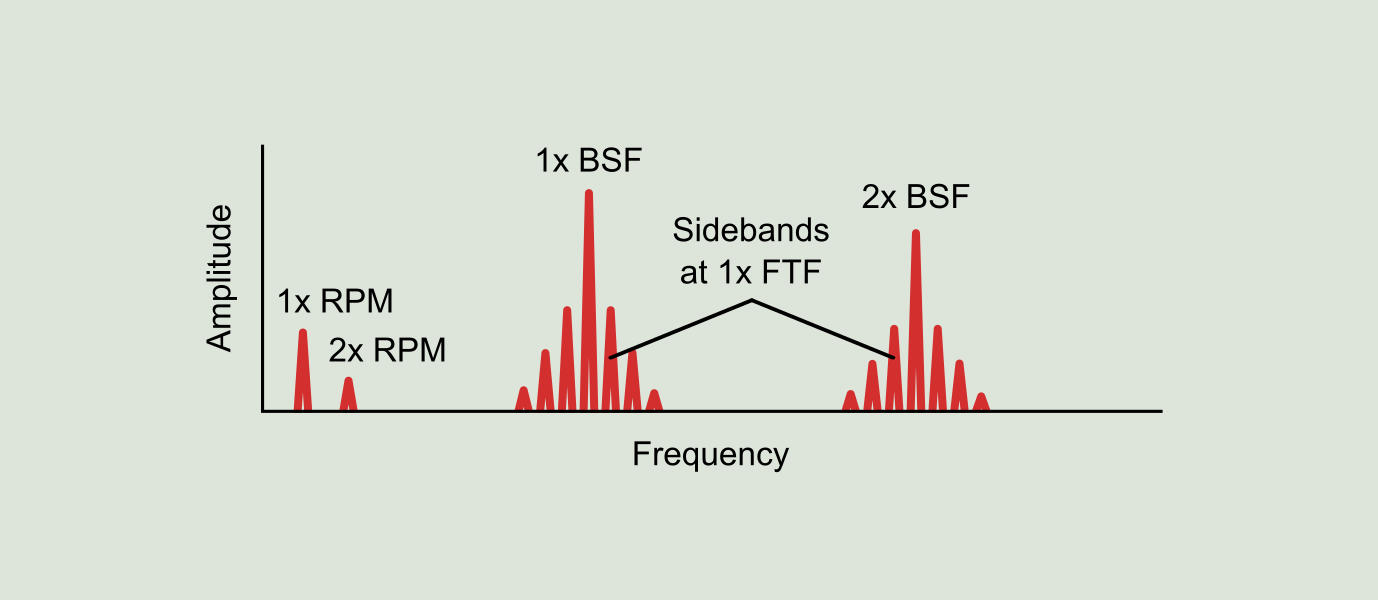

- Ball or roller defects: they are characterized by the presence in the spectrum of harmonics of the rolling element deterioration frequency (BSF). In most cases, the harmonic of greater amplitude usually indicates the number of deteriorated balls or rollers. They are usually accompanied by defects on the races.

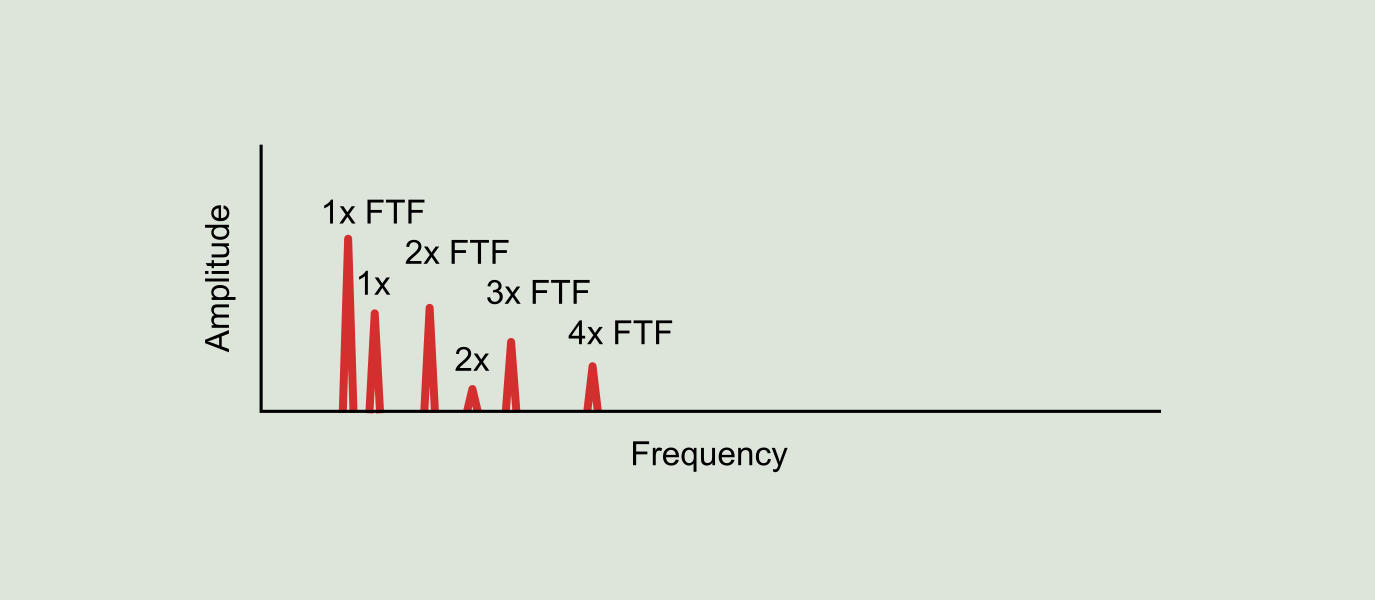

- Cage defects: are characterized by the presence in the spectrum of the cage failing frequency (FTF) and its harmonics. Generally, a defect in the cage is accompanied by defects in the races and the FTF usually modulates one of these race failure frequencies leading to sums and/or differences of frequencies.

- Defects of multiple components: it is quite common to find bearings with multiple deteriorated components, and in such case multiple failing frequencies and their corresponding harmonics will appear.

- Looseness: we can distinguish the following types:

- Excessive bearing internal clearance. Usually features a spectral signature characterized by the presence of synchronous vibration (rotating speed harmonics), subsynchronous vibration (0.5x RPM) and non-synchronous (1.5x RPM, 2.5xRPM, 3.5x RPM, etc.) . These frequencies sometimes can be modulated by the FTF.

- Looseness between bearing and shaft. Several rotation frequency harmonics appear and normally the dominant one is the 3x RPM.

- Looseness between bearing and casing. It presents several harmonics of the rotating frequency, being the peaks at 1x and 4x RPM the ones with higher amplitudes.

- Bearing misalignment: as already mentioned in the chapter about misalignment, spectral signatures are characterized by the presence of vibration at various harmonics of the rotating frequency, with the amplitude being the most significant at NB x RPM, where NB is the number of rolling elements in the bearing.

- Inadequate lubrication: lubrication problems are characterized by high frequency vibration (between 1 kHz and 20 kHz), with bands of peaks spaced apart from each other, due to the excitation of the resonance frequencies of the bearings in these frequency ranges.

Frequency bands for the analysis of bearing condition

The possibility of splitting the spectrum overall value into multiple frequency bands allows us to know in advance the areas in which the most typical problems are usually manifested and help us to identify them even before we can visualize the spectrum in frequencies and wave in the time. For typical machines where the aim is monitor low and medium frequency issues (umbalance, misalignment, looseness, etc.) and high frequency issues (bearings) we recommend to use the frequency bands indicated in the following table.

| Spectral parameter | Bandwidth |

| Imbalance, missalignment, looseness, rub and belt wear. | 1.5 to 2.5x RPM |

| Missalignment and looseness. | 1.5x to 2.5x RPM |

| Looseness, missalignment and BSF. | 2.5 to 4.5x RPM |

| First harmonics of the bearing fault frequencies BPFO, BPFI and BSF. | 4.5 to 20.5x RPM |

| Higher bearing fault frequencies harmonics and presence of frequencies related to electrical issues. | 20.5 to 50x RPM |

| High frequency spectral band, in units of acceleration (G's). Alarm parameter in case of early bearing deterioration stage, presence of cavitation or lack of lubrication. | 1 to 20 kHz |