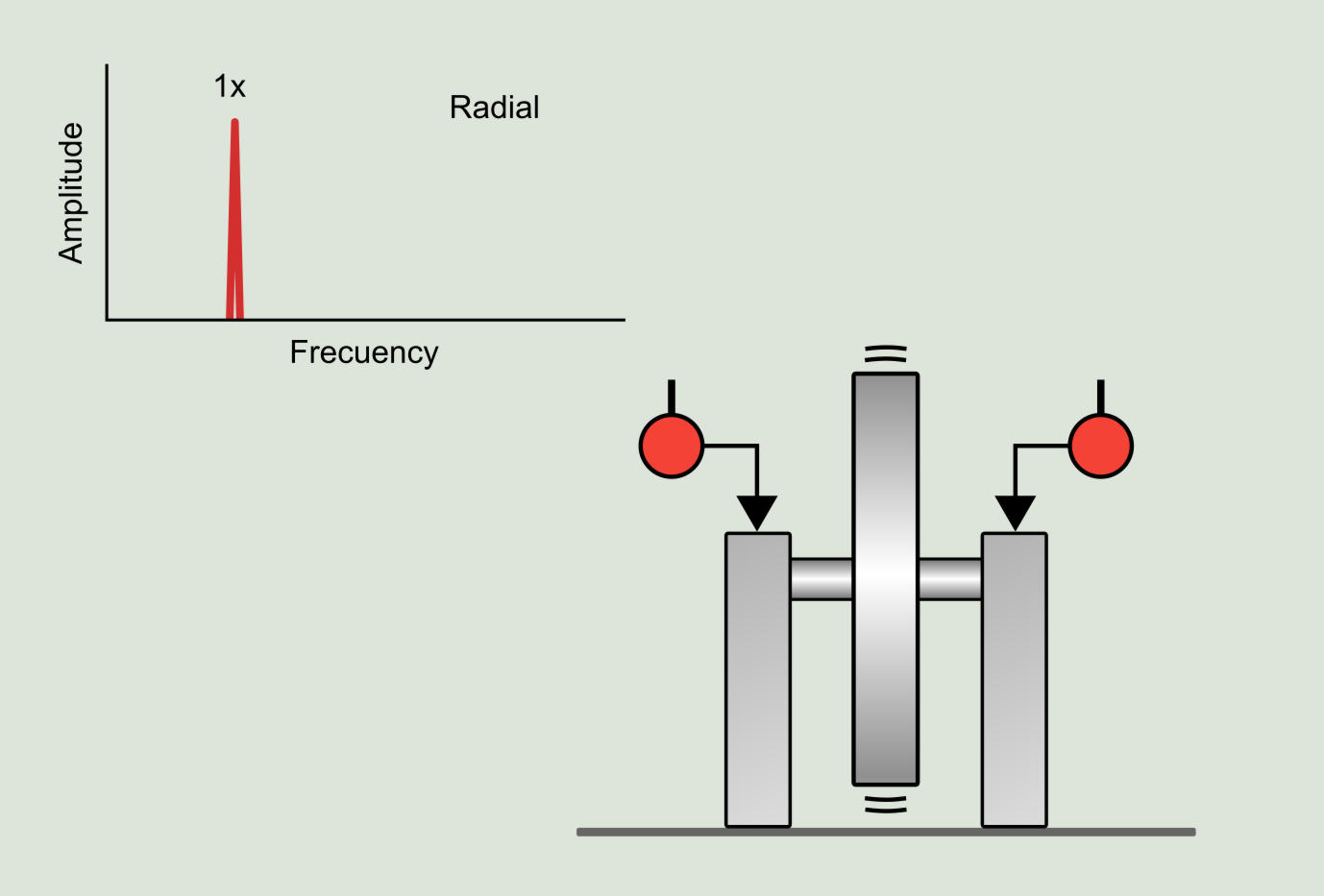

Single plane imbalance

It is also known as static imbalance and is usually the easiest problem to diagnose. Generally produced by non-uniform radial surface wear on rotors in which its length is negligible compared to its diameter. The source of the vibration is a centrifugal force which causes a displacement of the axis of rotation in the radial direction. In the absence of other problems the imbalance generates a pure sinusoidal waveform and therefore the spectrum presents dominant vibration with a frequency equal to 1xRPM of the rotor.

To correct the problem it is recommended to balance the rotor in a single plane (at the rotor center of gravity) with the proper mass at the angular position calculated with a balancing instrument.

Symptoms:

- Radial vibration at 1xRPM.

- Phase difference between a bearing horizontal and vertical direction of approximately 90°, allowing an acceptable variation of ±30°.

- There are no significant phase differences in the phase readings between both sides of the shaft in the same radial directions.

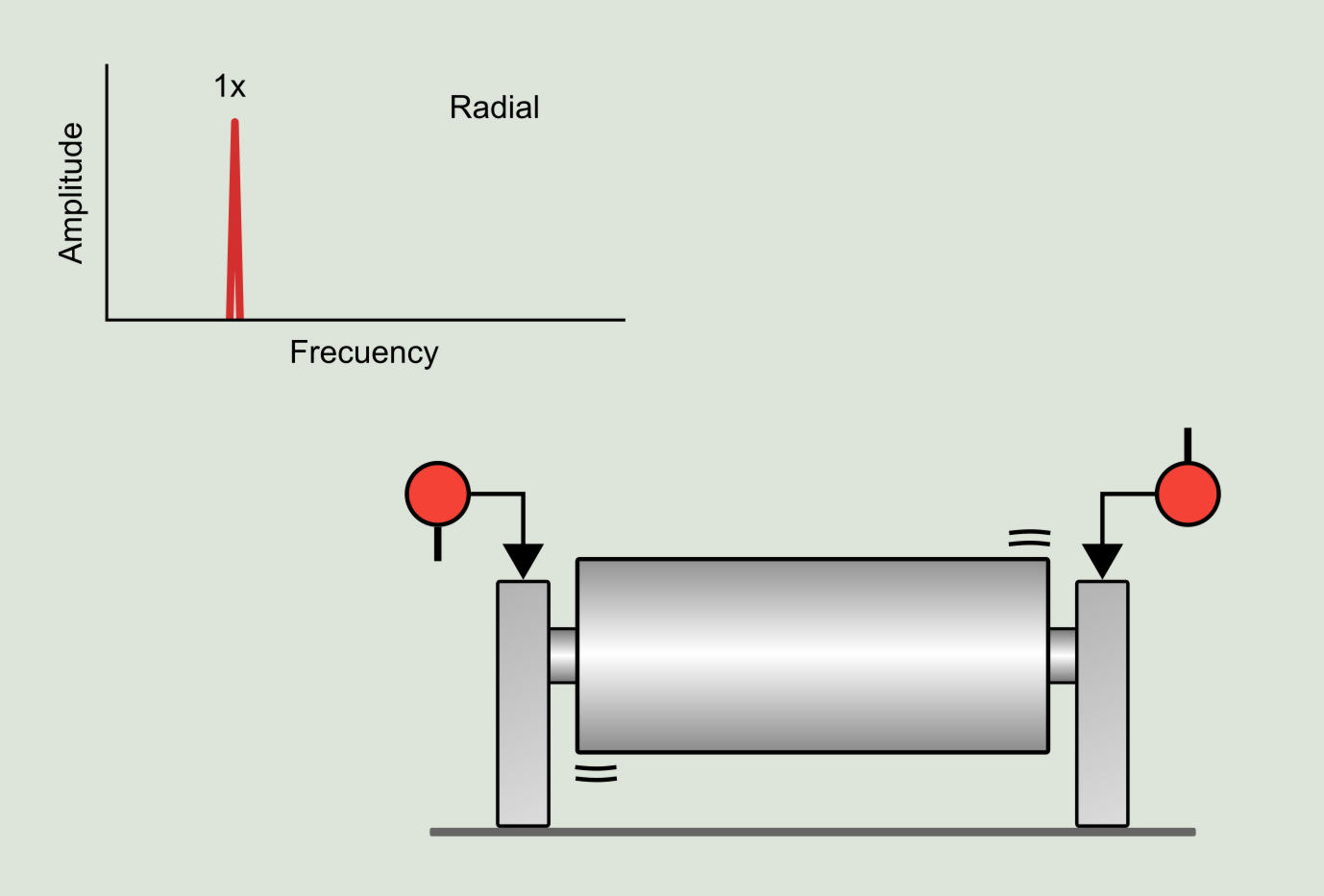

Two plane imbalance

In this case the origin of the imbalance is not a force, but a pair of forces. That is, two forces of equal magnitude and opposite direction. The dynamic imbalance occurs in medium and long rotors and it is mainly due to simultaneous radial and axial wear on the rotor surface. The spectrum exhibits dominant vibration and simultaneous sway at a frequency equal to 1xRPM of the rotor.

To correct the problem, it is recommended to balance the rotor in two planes with the appropriate masses and at the angular positions calculated with a balancing instrument.

Symptoms:

- Radial vibration at 1xRPM.

- Phase difference between bearing horizontal and vertical directions of approximately 90°, allowing an acceptable variation of ±30°.

- The radial phase reading will indicate that both sides of the shaft have a phase shift of 180°

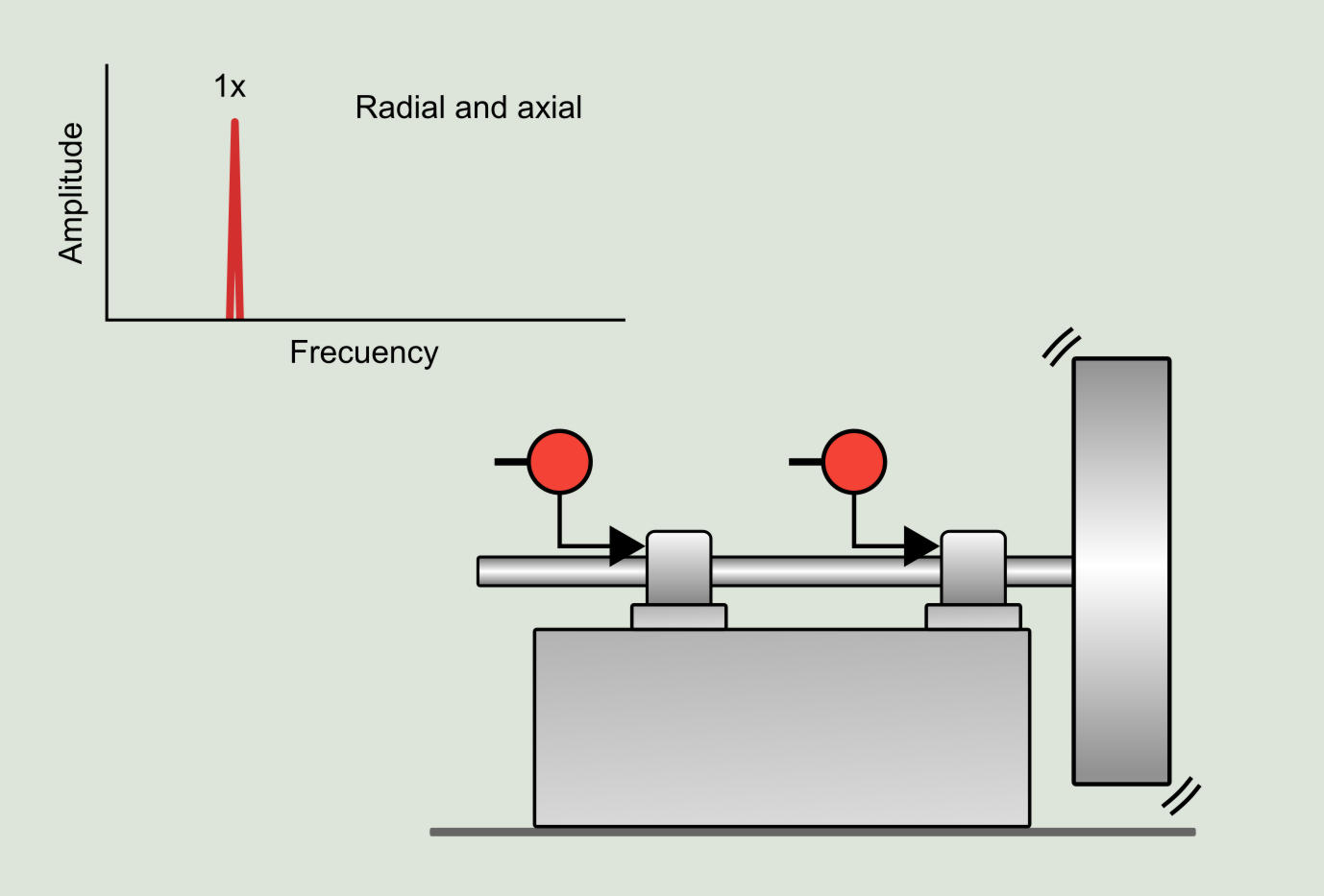

Overhung rotor

It occurs in rotors at the end of a shaft. It is produced by wear on the rotor surface and bending of the shaft. The spectrum presents dominant vibration at 1xRPM of the rotor, very notorious both in axial and radial directions.

To correct the problem, first check that the rotor has no eccentricity and that the shaft is not bent, then proper balancing must be performed.

Symptoms:

- Radial vibration at 1xRPM.

- Axial vibration at 1xRPM.

- Phase difference between bearing horizontal and vertical directions of approximately 90°, allowing an acceptable variation of ±30°.

- Axial phase readings between bearings normally in phase.

- Phase measurements in radial direction between the bearings might be out of phase.