Eccentric gear or bent shaft

Gear eccentricity or bent shaft causes modulation in the GMF at the rotating speed of the eccentric gear. Modulation may also occur at the shaft rotating frequencies in case of a sufficiently serious problem. In case of an eccentric gear, its peak at 1x RPM will have greater amplitude and the side bands will appear spaced at that same 1x RPM frequency.

Symptoms:

- Increased amplitude in 1x, 2x and/or 3x GMF.

- Significant sidebands around 1x, 2x and/or 3x GMF at the 1x RPM frequency of the gear causing the problem.

- Increased amplitude at 1x RPM of the gear that has the problem and, in case of a serious problem, harmonics will also appear.

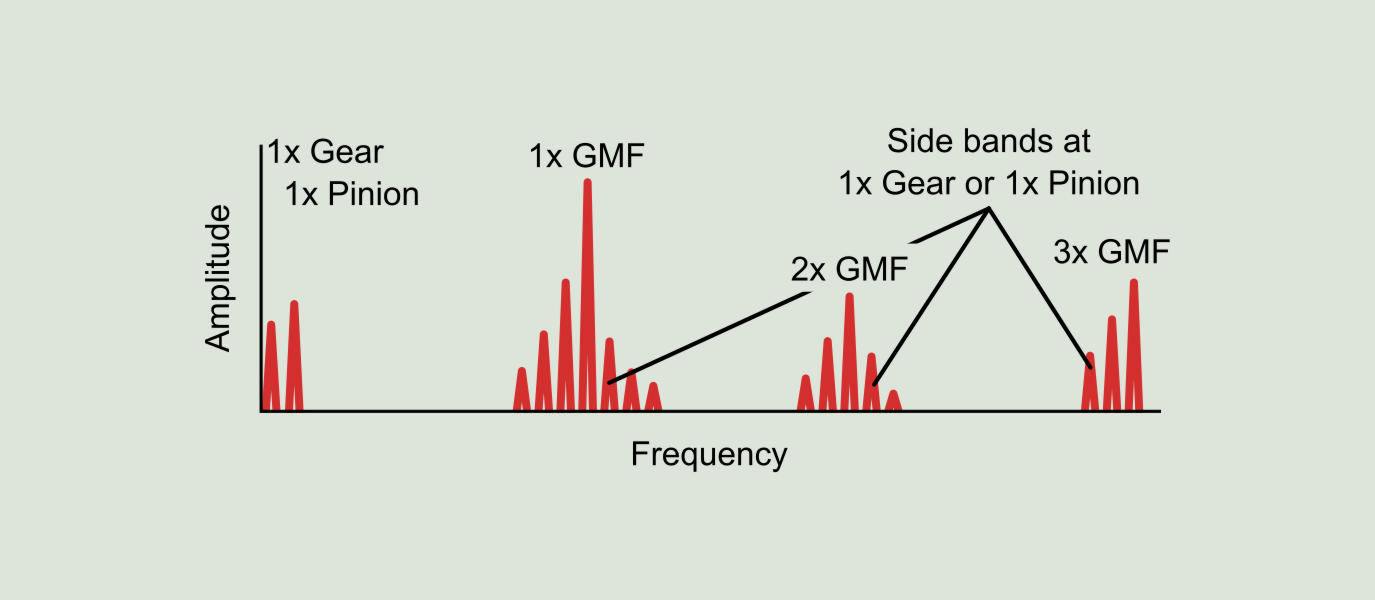

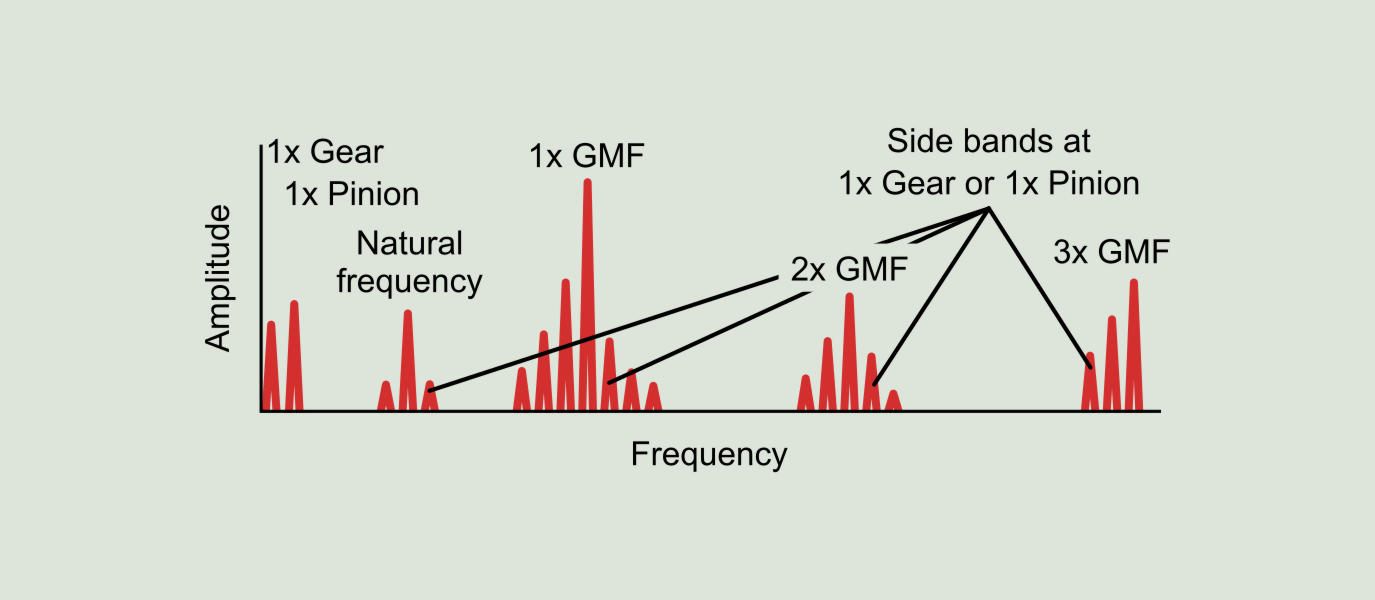

Pitch diameter wear or broken tooth

Gear wear causes important peaks at the GMF and its harmonics. In addition, the friction excites the natural frequency of the gear, which causes the appearance of new frequencies in the spectrum that could correspond with the resonance frequency of the pinion or the crown. The main indicators are the appearance of the resonance frequencies of the gear with sidebands and the size and number of sidebands in 1x, 2x and/or 3x GMF. It is not enough just to study the amplitudes of the GMF and its harmonics as these better reflect load and alignment problems.

Symptoms:

- Increased amplitude at 1x, 2x and/or 3x GMF.

- Important sidebands around 1x, 2x and/or 3x GMF at the frequency 1x RPM of the worn gear.

- Peaks corresponding to the resonance frequency of the pinion or the gear.

- Side bands at 1x RPM of the worn gear around the resonance frequency.

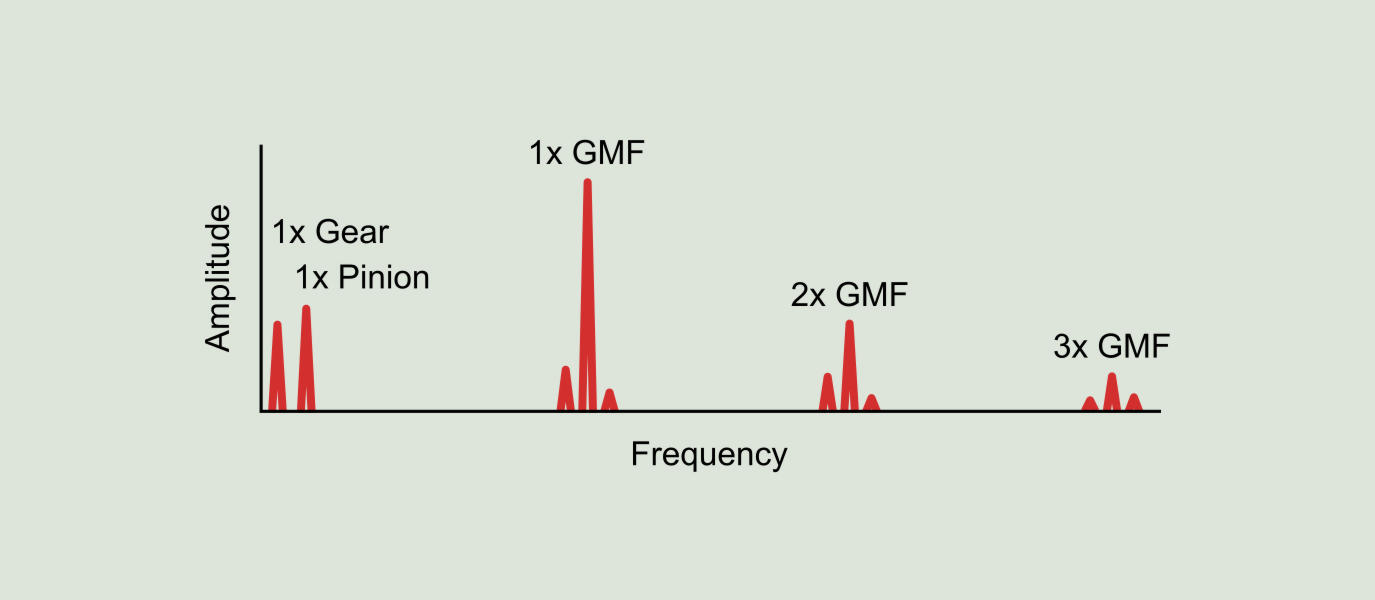

Overload

Usually affects the GMF and its harmonics to a greater extent than to the relatively few and lower amplitude running speed sidebands. Variations in the amplitude of the GMF and its harmonics (without significant changes in the sidebands) does not, on its own, indicate the presence of a problem. Even if the load remains constant, GMF of the gear that supports the load can constantly change without any deterioration of its condition. There may also be a change in the load level with a strong effect on the spectrum without this implying the presence of a problem.

Symptoms:

- Higher amplitudes in 1x, 2x and/or 3x GMF.

Misalignment

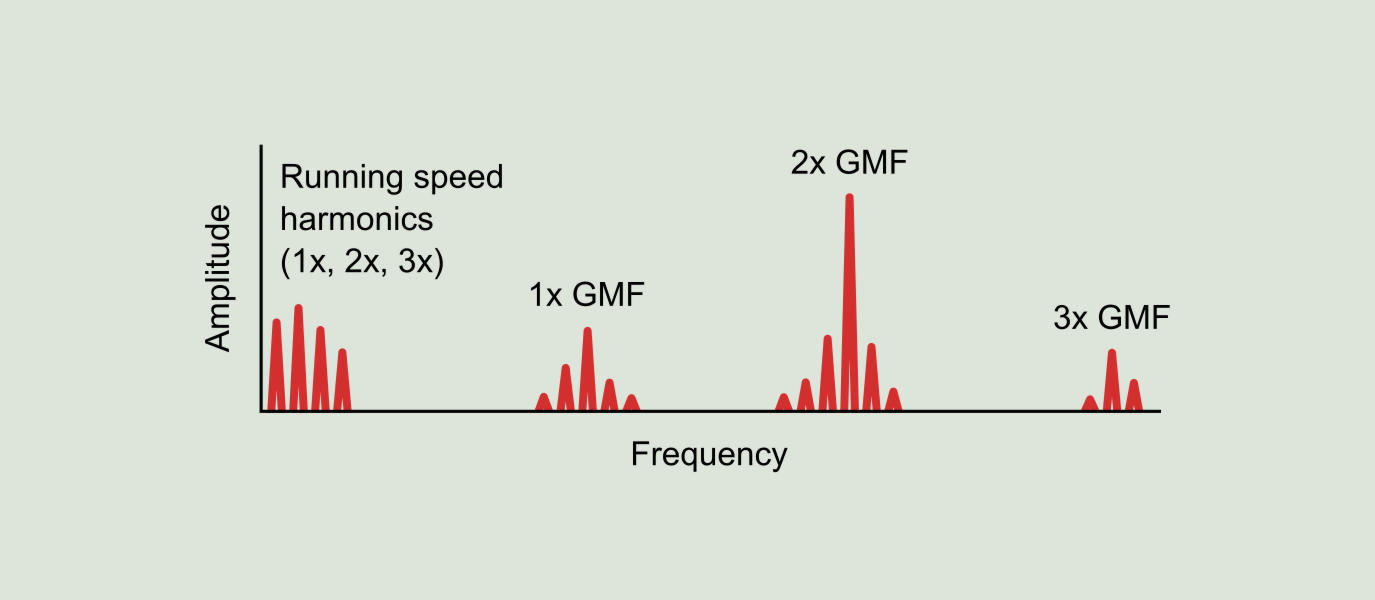

The predominant vibration occurs at 1x RPM and at 2x RPM of the misaligned shafts, being even able to excite the gearmesh frequency so the first three harmonics of the GMF might appear. It changes the normal rotation of the gears by making more difficult to engage the teeth in the areas where they are misaligned, causing a momentary reduction of the rotating speed. The FFT displays this phenomenon via peaks at twice the rotating speed and at twice the gearmesh frequency. Each of these two symptoms, mainly the peak in 2x GMF, may be due to an alignment problem in the gear, which in turn, could be caused by a misalignment in a coupling or other external factors as for example a problem in the machine foundation.

Symptoms:

- Amplitude increase in 2x GMF.

- Peaks in other harmonics of the GMF (1x, 3x, etc.).

- Important sidebands in 2x GMF and in 1x or even 2x RPM.

- Harmonics of the rotating speed of each shaft in 2x and even 3x RPM.

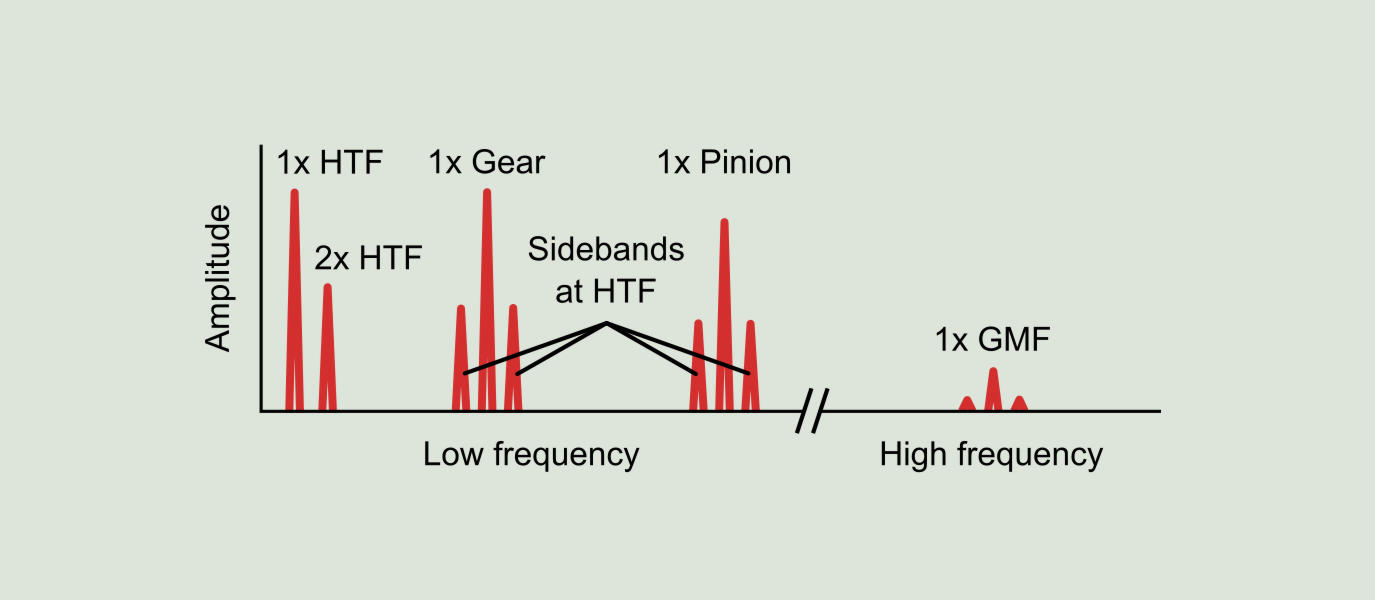

Hunting tooth frequency

The so-called hunting tooth frequency (HTF) is the rate at which a tooth in a gear engages to a particular tooth in another gear. If the transmission ratio between the two gears is an integer number, the hunting tooth frequency will match the RPM of the largest gear and the same two teeth will be in contact once per revolution. This causes uneven wear on the gears, since a small defect in one tooth will repeatedly contact the same tooth in the other gear, causing localized wear on these two teeth. For this reason, gearboxes are not built with these simple transmission ratios, unless absolutely necessary. Ideally, the hunting tooth frequency should be as low as possible to evenly distribute the wear on the two gears. This is achieved by making the number of teeth in each gear a prime number. In some gearboxes, the hunting tooth frequency will appear in the vibration spectrum and when this is the case, its trend over time should be monitored, since under these circumstances wear develops quite rapidly.

Symptoms:

- Peak at 1x HTF and possibly at 2x HTF.

- HTF sidebands around 1x RPM of each shaft.

- HTF sidebands around 1x GMF and its harmonics.

- Low frequency gear pulsating noise.