Mechanical looseness can be of very different nature: not enough tightening between different mechanical elements (loosening of bolts, fracture of fixations, etc.), increase of tolerances produced by wear and tear (excessive gaps in rolling element bearings, sleeve bearings, gears, etc.), etc. Looseness manifests in the vibration measurements provided that there is a source of excitation due to a problem other than looseness, such as unbalance, misalignment, etc., so that small external excitation forces can result in high vibration amplitudes, in the presence of looseness.

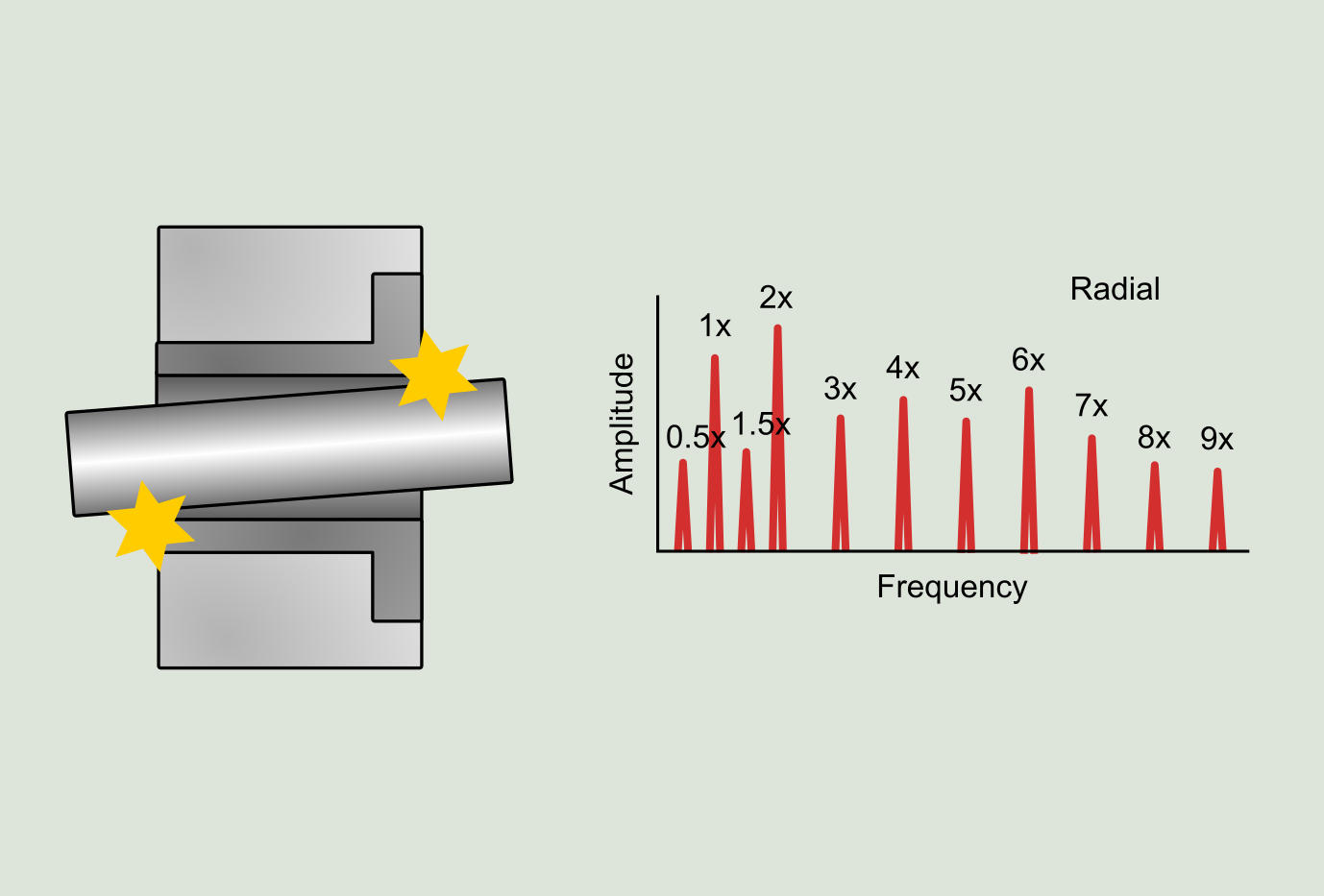

Looseness is characterized by the presence in the frequency spectrum of multiple harmonics of the shaft rotating speed. The vibration levels experienced by the machine are often important. Depending on the evolution of the looseness, harmonic peaks of the rotating frequency (1x, 2x, 3x, etc.), half harmonics (1,5x, 2,5x, 3,5x, etc.) and even subharmonics of that same frequency (0,5x) can appear in the spectra. On the other hand, the time waveform will be characterized by being erratic and without any pattern of repetition.

We can make a general classification of looseness, distinguishing between looseness of rotating elements (rolling element bearings, sleeve bearings, couplings, rotors, etc.) and structural looseness (benches, casters, anchor bolts, etc.). Each one of these has its own characteristics that are discussed below.

Rotating element looseness

This type of looseness is characterized by a spectrum containing many frequencies related to the rotating frequency of the rotor, being able to distinguish: harmonics (1x, 2x, 3x, etc.), subharmonics (0.5x) and half harmonics (1.5x, 2.5x, 3.5x, etc.). They generally manifest more clearly in the radial directions of measurement (horizontal and vertical) than in the axial direction.

As the wear increases, the frequency spectrum changes, allowing a classification of the severity of the looseness into the following four groups:

- Incipient looseness: presence of the first four or five harmonics of the rotating speed, showing less amplitude the higher harmonics.

- Potentially serious looseness: increase of the amplitude of the first harmonic of the rotating speed and appearance of very low amplitude half harmonics.

- Serious looseness: increase of the amplitude of the harmonics and half harmonics of the rotating speed.

- Severe looseness: it is characterized by presenting half harmonics, harmonics and subharmonics of the rotating frequency of the rotor, so that a wide energy band is observed in the spectrum.

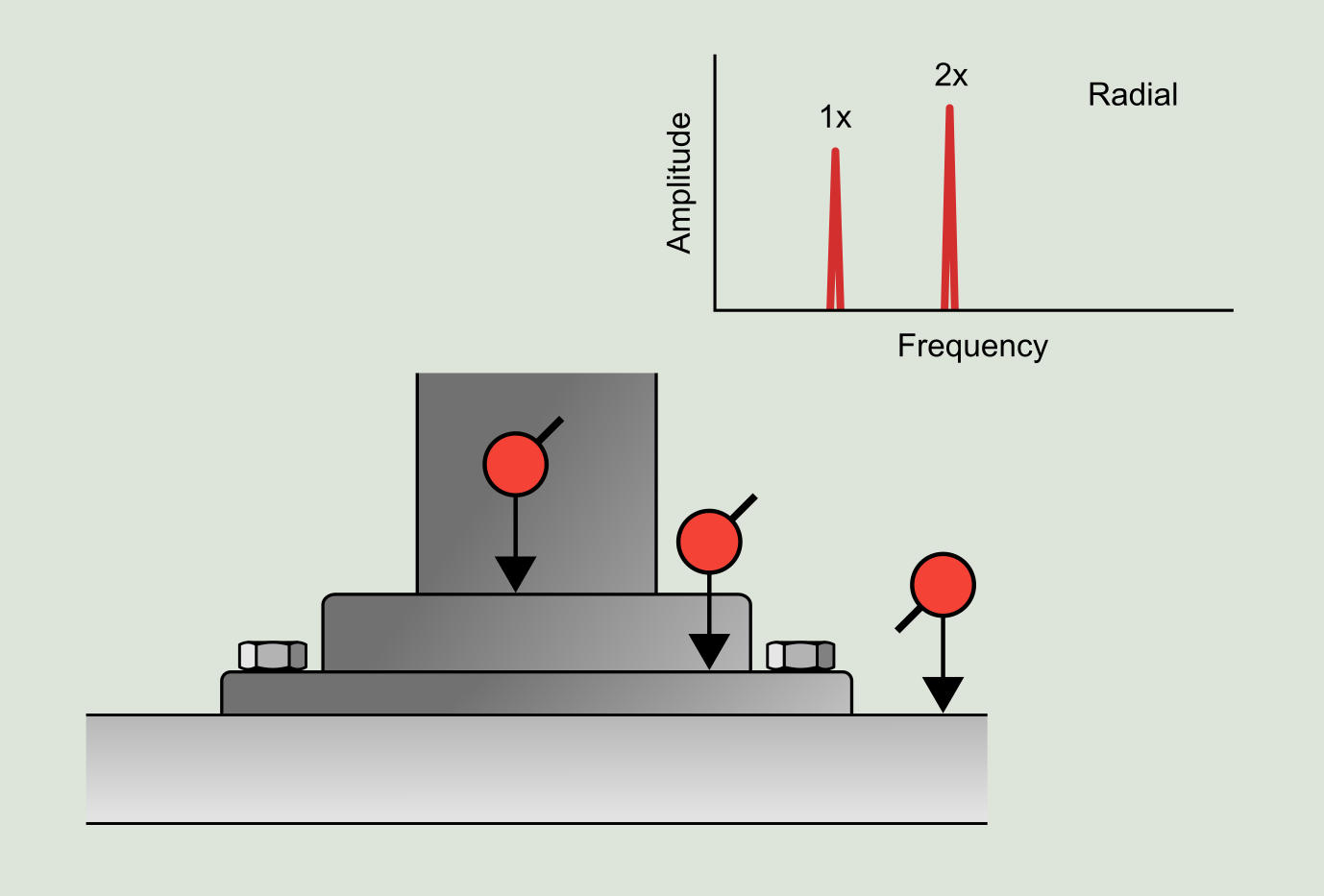

Structural looseness

These refers to looseness associated with the mechanical non-rotating elements of the machine: bench fixings, joints between pipes, bearing casings, etc. Normally, it manifests more clearly in the radial measurement directions than in the axial ones, with the presence in the frequency spectrum of several harmonics of the rotating speed of the shaft. The comparison of the amplitude of the 2x and 3x harmonics with respect to the frequency at 1x provides an indication of looseness severity, so that an amplitude of these harmonics above 50% of the amplitude of the peak at 1x, points to a greater severity of the looseness. The reason why this kind of looseness manifests in frequency spectra with several harmonics of the rotating frequency (1x, 2x, 3x, 4x, etc.) is illustrated in the following figure. The rotor presents a slight unbalance as a driving force of the looseness due to loosening of the fixings between the bearing supports and the bench. In the four stages of the figure we can see that as the unbalance heavy spot rotates to complete a full revolution, there are four forces or impulses, indicated in the four stages, two of which are due to the unbalance and the other two to the return of each of the sides of the support to the bench. This will give rise to several harmonics of the rotating frequency in the vibration spectrum.

To identify and locate whether or not looseness is present between two structural elements, such as a motor foot and the bench, due to loosening of the bolts or breakage of the anchor, there is a very simple method that consists of taking vibration amplitude and phase readings, in all possible measurement directions (axial, horizontal and vertical) in the two elements under analysis. The data obtained can give us two possible well differentiated results, according to which we will determine with total reliability the presence or not of looseness between them:

- If the spectra obtained in the same direction for the two elements shows similar amplitudes and in addition the phase readings are identical then this is indicative that there is a good union between the two elements.

- On the other hand, if the amplitudes of the harmonic peaks of the rotating frequency in the same measurement directions for the two elements are different, and in addition there are important differences in phase between them, then we can confirm the existence of looseness between both elements.