Cyber-Physical Spaces

The new industrial revolution, known as Industry 4.0, brings us a new vision of how to generate smart factories. The first industrial revolution introduced mechanized production with the steam machine, the second introduced mass production with the electric motor, and the third introduced process automation with PLCs; however, the digital transformation of the industry will take place thanks to the concept of cyber-physical spaces.

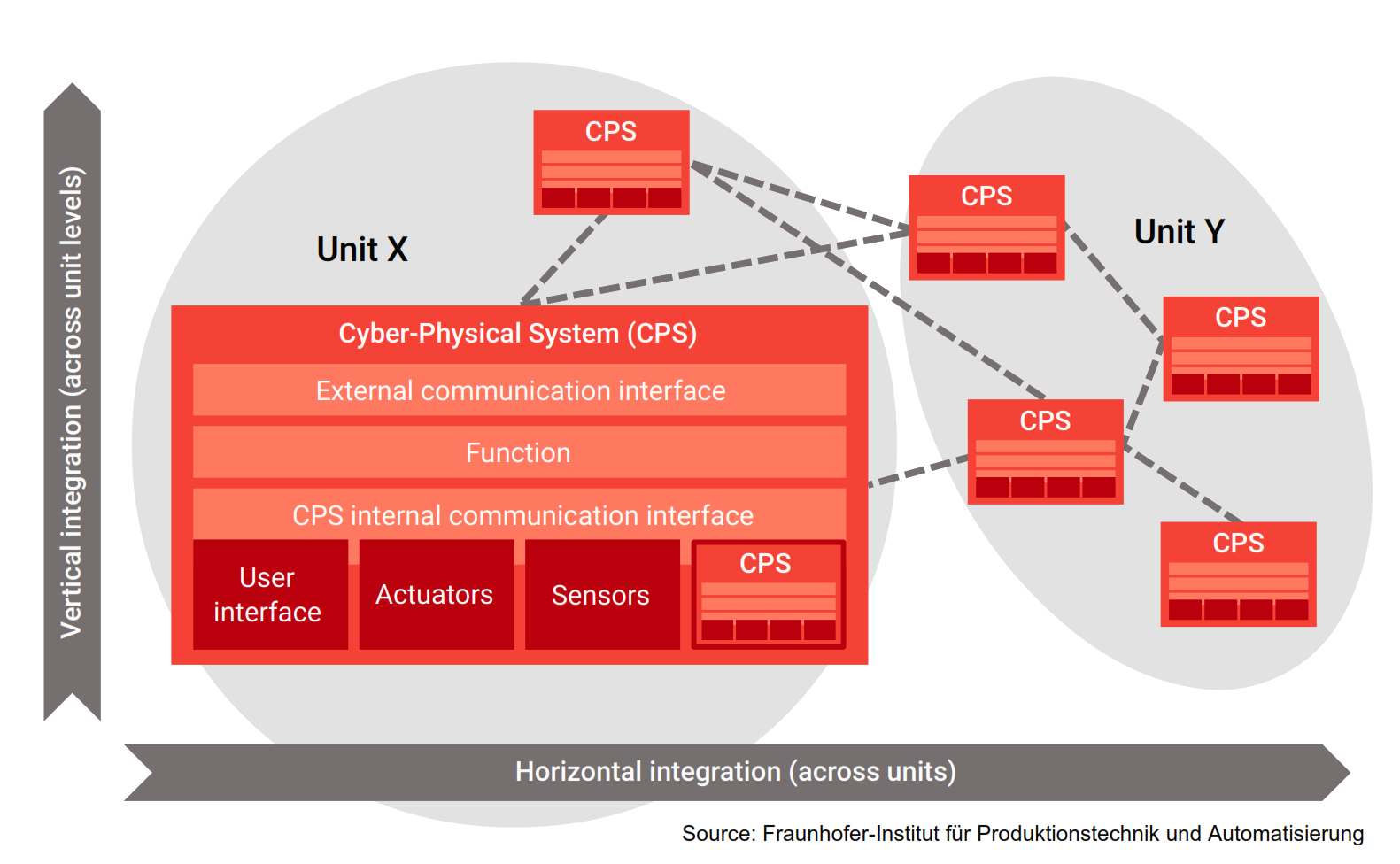

The concept of cyber-physical space refers to the environment where different systems with particular data processing and storage capabilities, and communication capabilities interact with the production processes. Also, the connection of the productive processes (physical) with the virtual world and the digital networks to achieve a higher level of control and processes optimization becomes possible. This way, the high level of interaction between the cyber-physical systems (CPS) and other technologies such as big data and cloud computing allows for compliance with the basic concept of the Industry 4.0, the smart factory.

How is a cyber-physical space formed?

As mentioned before, a cyber-physical space comprises a series of systems. However, its components can be described as follows:

-

Cyber-physical systems (CPS)

these systems are the ones described before with the capabilities that allow the interaction between the virtual world and the physical production processes. They can be found in different areas inside and outside the factory, but they must always be interconnected to belong to the same cyber-physical space. -

External communication interface

this is part of the cyber-physical system, and it offers the opportunity to view and control the interaction of a cyber-physical system with other systems that belong to the same space. -

Functions

another internal component of the cyber-physical system, which is responsible for the main functions of the system as the name suggests. -

CPS internal communication interface

similar to the external communication interface, but this one is dedicated to the interaction of the components inside the same cyber-physical system. -

User interface

it is connected to the other components of the system through the internal communication interface, allowing the person in charge to monitor the general operation, make the necessary decisions, and take the necessary actions to achieve the objectives. -

Sensors and actuators

these are connected to the system from the productive processes in the factory.

Cyber-physical space features

Among the features of a cyber-physical space, we can mention adaptability, independence, collaboration security, and usability.

It is important to highlight that one of the most important features of a cyber-physical space is it allows the integration of different systems, both vertically (inside the organization) and horizontally (the organization with the exterior, other organizations, etc.). Vertically speaking, integrating the different departments and the different hierarchical levels in the organization is possible, and horizontally speaking, we can observe the integration of different areas or phases of the cyber-physical space. Moreover, there is no cyber-physical space if there is no horizontal integration, as that would be the case of an internal system applied only by the organization, not a cyber-physical space.

What is the role of predictive maintenance in the Industry 4.0?

Although maintenance tasks are generally considered traditional, and it is difficult to relate them to Industry 4.0, predictive maintenance has a very important role in this industrial revolution. In a smart factory, the level of integration is so high that nothing can be taken for granted, which is why the maintenance of the machinery involved in the productive processes must also be included.

Predictive maintenance grants the ability to monitor the operating conditions over time, and it also allows the use of systems such as Power-MI. Thus, information can be quickly sent to different departments for more optimized decision making, and to ensure any maintenance need is covered at the right moment. In other words, the interaction inside the cyber-physical space is achieved.

Power-MI is a software platform in the cloud that allows the integration of structured data from different sources. The data is processed anonymously to create a comparison between assets of the same type and which operate within the same industrial sector. This way, horizontal interaction is achieved.

Likewise, inside an organization, Power-MI allows to link the measures taken on the machines, process such information to obtain work orders for the maintenance department and calculate the savings for the financial department. This is now possible thanks to cloud computing.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more